High-temperature-resisting SCR (Selective Catalytic Reduction) flue gas denitration catalyst and preparation method thereof

A denitrification catalyst and high-temperature-resistant technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as difficult molding and demolding during the production process, difficulty in adapting the catalyst to high temperature, and unsatisfactory denitrification efficiency. Achieve the effects of widening the working temperature window, long life, and improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

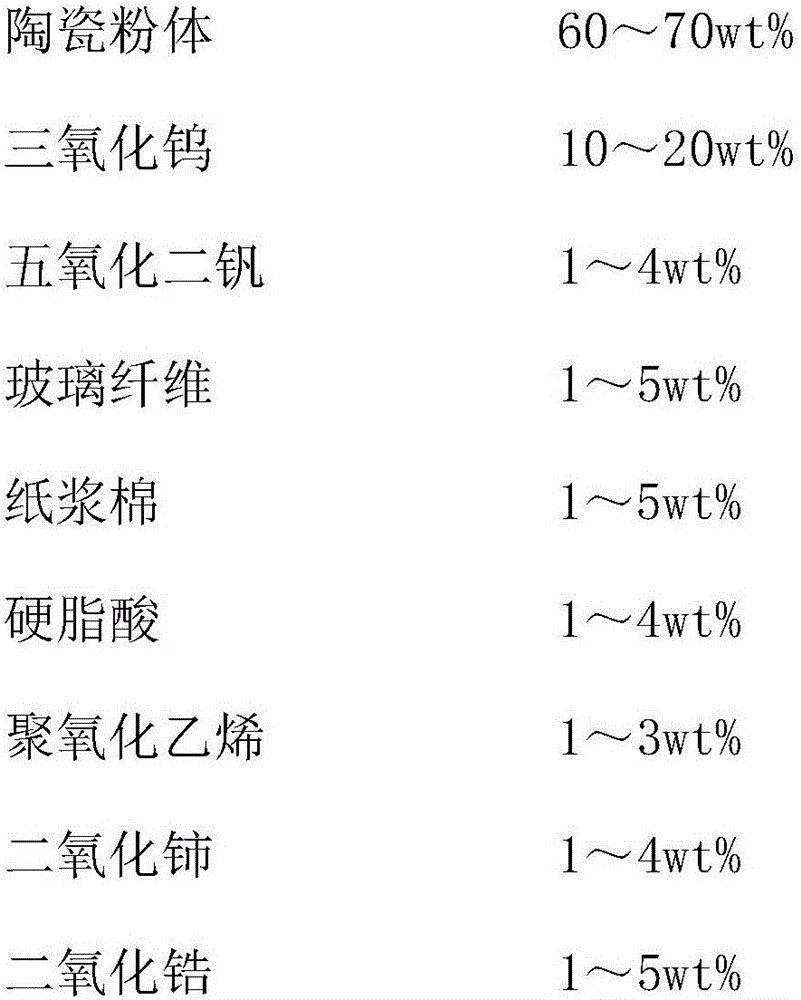

Method used

Image

Examples

Embodiment 1

[0023] (1) SiC-Al 2 O 3 Preparation of composite carrier: take silicon carbide powder with a particle size of 100 nm and add it to a dodecyl phosphate ester triethanolamine alcohol solution with a concentration of 0.01 mol / L, stir at 60 °C for 4 h, suction filtration, and use ethanol and After washing with distilled water, vacuum drying at 40°C for 4h;

[0024] The modified dry powder was placed in an aqueous solution of aluminum chloride with a mass fraction of 4%, stirred evenly at 20°C, and then added with a sodium carbonate solution with a mass fraction of 15%, and stirred until the solution produced a white gelatinous precipitation. After completion, it was left to age at room temperature for 4 hours;

[0025] After the aging, the precipitate is washed successively with a weakly alkaline solution with a pH of 8 and distilled water, and washed 4 to 5 times respectively. After the washing is completed, vacuum drying at 40° C. to obtain the SiC-Al 2 O 3 Composite carrier...

Embodiment 2

[0029] (1) SiC-Al 2 O 3 Preparation of composite carrier: take silicon carbide powder with a particle size of 300 nm and add it to a dodecyl phosphate ester triethanolamine alcohol solution with a concentration of 0.02 mol / L, stir at 70 °C for 5 h, suction filtration, and use ethanol and After washing with distilled water, vacuum drying at 50°C for 5h;

[0030] The modified dry powder was placed in an aqueous solution of aluminum chloride with a mass fraction of 6%, stirred evenly at 25°C, and then added with a sodium carbonate solution with a mass fraction of 20%, and stirred until a white gelatinous precipitation was produced, and the precipitation was complete. After 5 hours of aging at room temperature;

[0031] After the aging, the precipitate is washed successively with a weakly alkaline solution with a pH of 9 and distilled water, and washed 4 to 5 times respectively. After the washing is completed, vacuum drying at 50° C. to obtain the SiC-Al 2 O 3 Composite carrie...

Embodiment 3

[0035] (1) SiC-Al 2 O 3 Preparation of composite carrier: take silicon carbide powder with a particle size of 500 nm and add it to a dodecyl phosphate ester triethanolamine alcohol solution with a concentration of 0.015 mol / L, stir at 80 °C for 6 h, suction filtration, and sequentially use ethanol and After washing with distilled water, vacuum drying at 60°C for 6h;

[0036] The modified dry powder was placed in an aqueous solution of aluminum chloride with a mass fraction of 8%, stirred uniformly at 30 ° C, and then added with a sodium carbonate solution with a mass fraction of 20%, and stirred until a white gelatinous precipitation was produced, and the precipitation was complete. After 6 hours of aging at room temperature;

[0037] After the aging, the precipitate is washed successively with a weakly alkaline solution with a pH of 8.5 and distilled water, and washed 4 to 5 times respectively. After the washing is completed, vacuum drying at 70° C. to obtain the SiC-Al 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com