A high power density substrate embedded with diamond copper and its preparation method

A high power density, diamond technology, used in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of high price, low thermal conductivity, high relative density, etc., to save raw materials, high thermal conductivity, high density small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

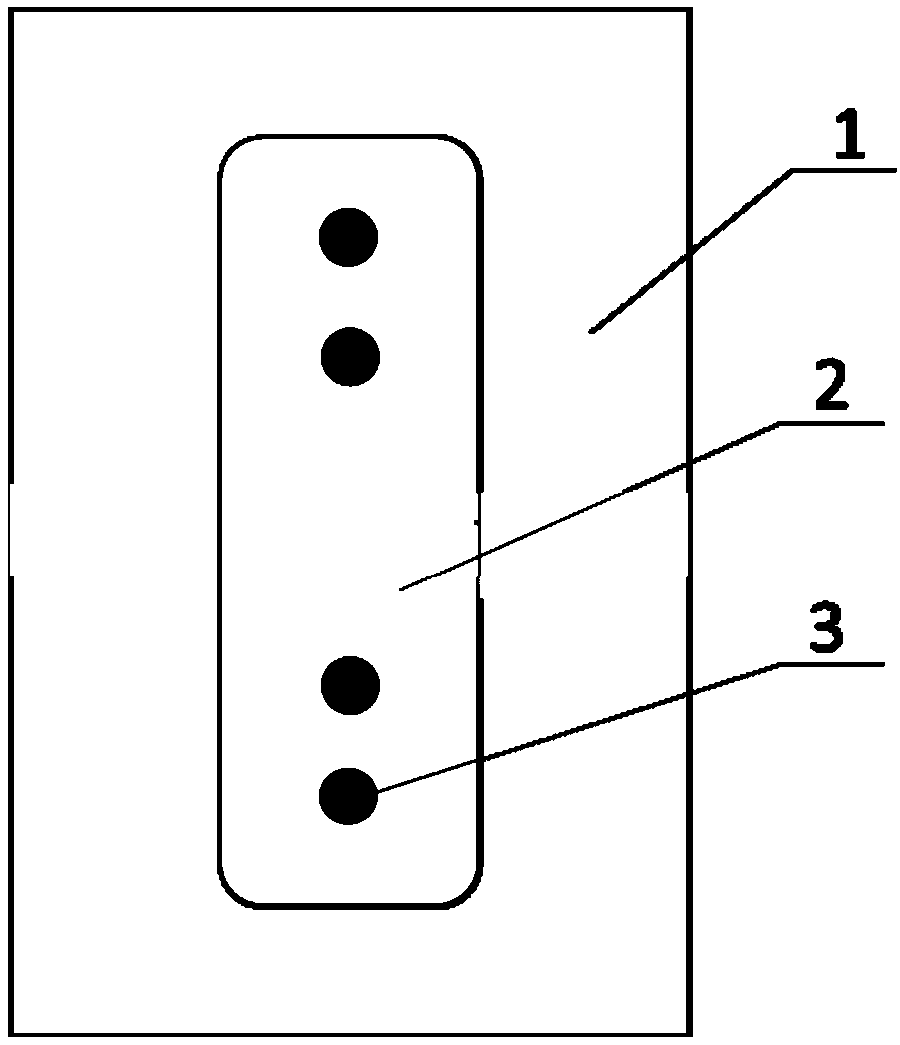

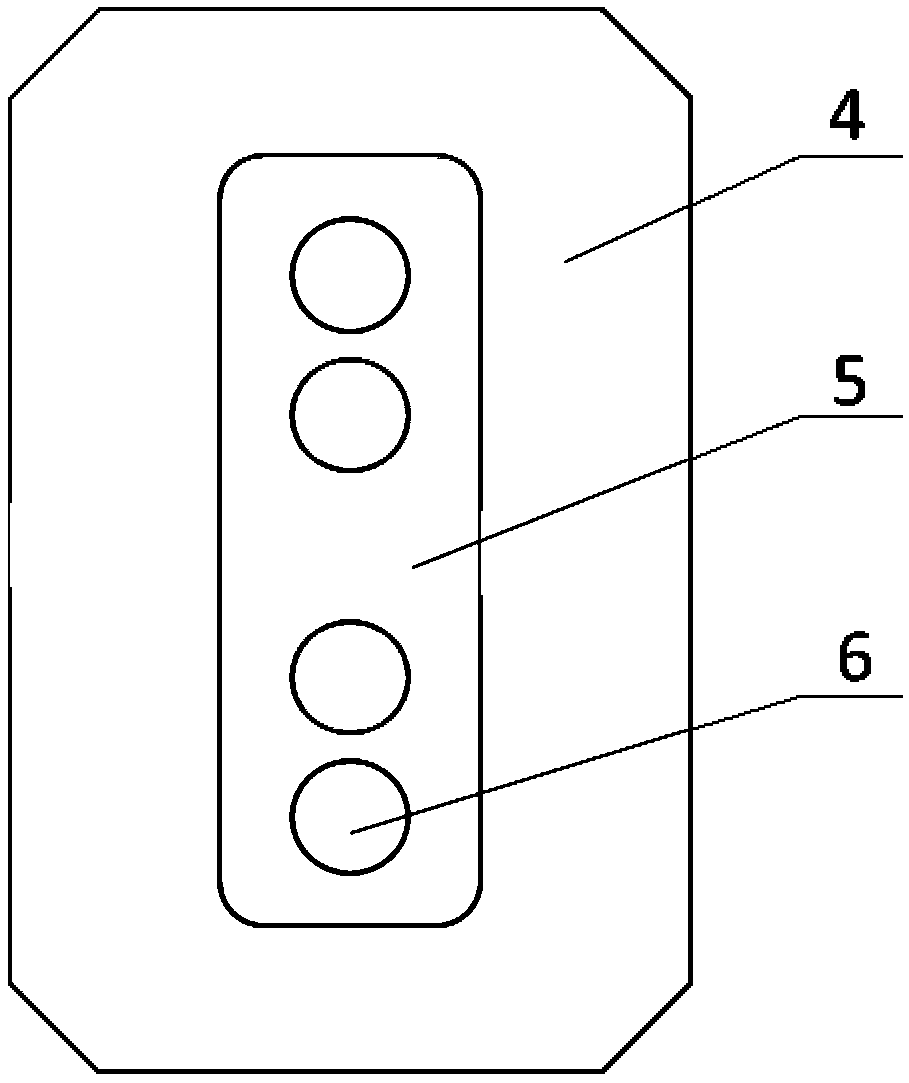

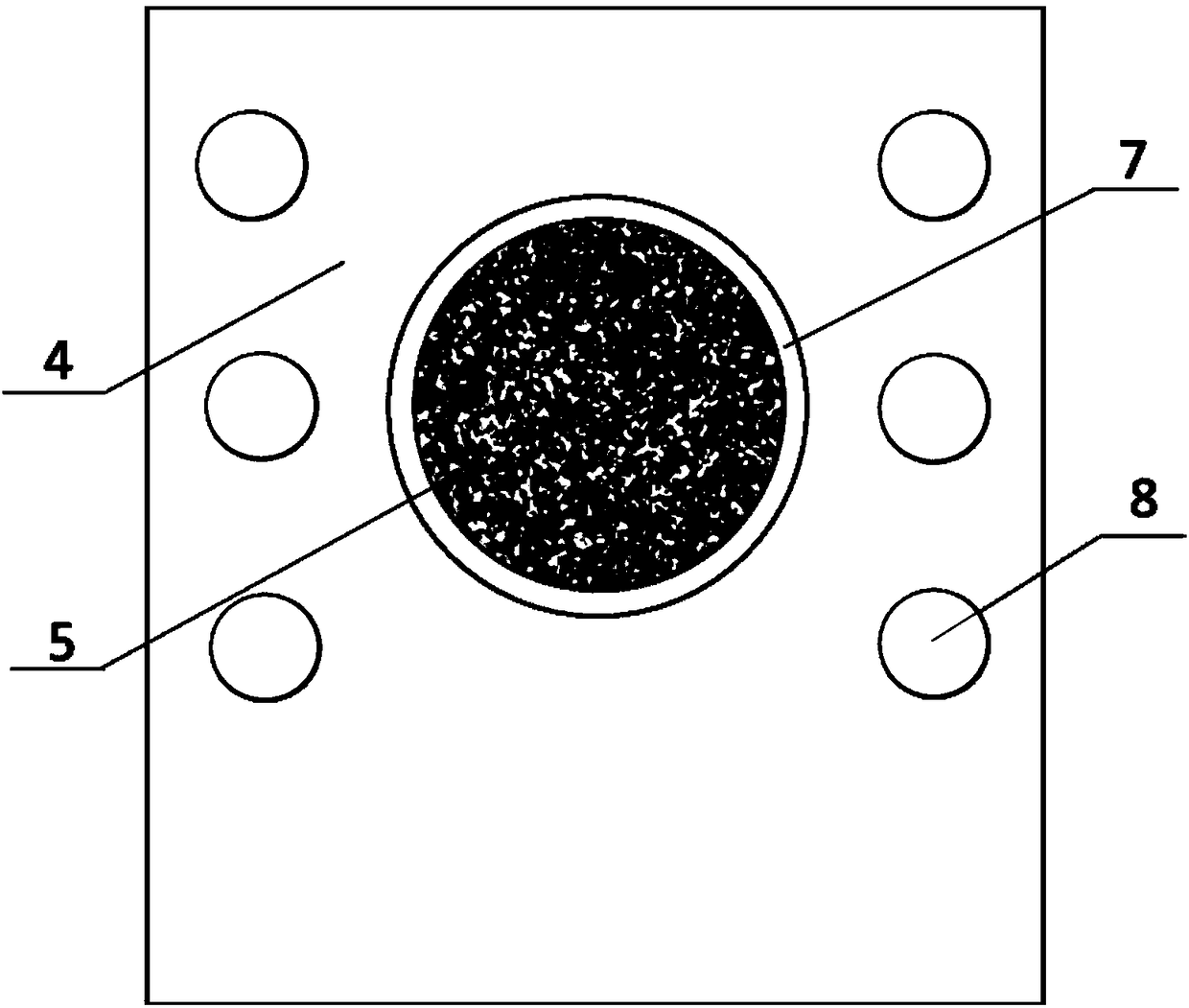

[0024] combine figure 1 and figure 2 To illustrate this example, a porous diamond preform is placed at position 2 of the near-net mold, and a high-power-density substrate with 5×20 mm rectangular diamond / copper embedded in oxygen-free copper is prepared by vacuum pressure infiltration technology, and the thermal load power is applied 400W / cm 2 , The junction temperature of the chip tested by a thermal imager is 56°C, which is 8-10°C lower than the junction temperature of the oxygen-free copper substrate.

Embodiment 2

[0026] combine figure 1 and figure 2 To illustrate this example, a porous diamond preform is placed at position 2 of the near-net mold, and a high power density substrate with 8×30mm rectangular diamond / copper embedded in oxygen-free copper is prepared by vacuum pressure infiltration technology, and the thermal load power is applied 600W / cm 2 , The junction temperature of the chip tested by a thermal imager is 63°C, which is 20-25°C lower than the junction temperature of the oxygen-free copper metal substrate.

Embodiment 3

[0028] combine figure 1 and figure 2 To illustrate this embodiment, first add molybdenum powder to position 1 of the near-net shape mold and then sinter it into porous molybdenum, fill diamond powder at position 2 of the near-net shape mold, and sinter again to obtain a composite porous preform inlaid with diamonds, using vacuum pressure The high power density substrate of 8×30mm rectangular diamond / copper embedded in molybdenum copper was prepared by impregnation technology, and the applied thermal load power was 400W / cm 2 , The junction temperature of the chip tested by a thermal imager is 64°C, which is 18-20°C lower than the junction temperature of the molybdenum-copper metal substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com