Epoxy resin composition and cured product thereof

A technology of epoxy resin and composition, which can be used in electric solid devices, chemical instruments and methods, semiconductor/solid device parts, etc., can solve the problems of limited use of solvent-soluble varnishes and no flame retardancy, etc. Achieve the effect of good solvent solubility, low dielectric constant and low dielectric loss tangent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0136] Next, this invention is demonstrated more concretely based on an Example and a comparative example, Hereinafter, "part" and "%" are a mass basis.

[0137]

[0138] Measured under the following conditions.

[0139] Measuring device: "HLC-8320GPC" manufactured by Tosoh Corporation,

[0140] Column: Guard column "HXL-L" manufactured by Tosoh Corporation

[0141] + "TSK-GEL G2000HXL" manufactured by Tosoh Corporation

[0142] + "TSK-GEL G2000HXL" manufactured by Tosoh Corporation

[0143] + "TSK-GEL G3000HXL" manufactured by Tosoh Corporation

[0144] + "TSK-GEL G4000HXL" manufactured by Tosoh Corporation

[0145] Detector: RI (differential refraction) detector

[0146] Data processing: "EcoSEC-WS Version 1.12" manufactured by Tosoh Corporation

[0147] Determination conditions: column temperature 40°C

[0148] Developing solvent Tetrahydrofuran

[0149] Flow rate 1.0ml / min

[0150] Standard: In accordance with the measurement manual of the aforementioned "EcoSEC-W...

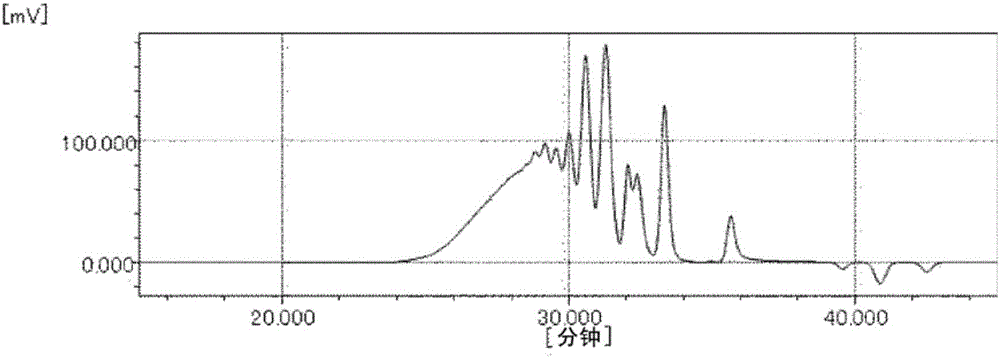

Synthetic example 1

[0159] Add 883 parts of p-tert-butylphenol, 88 parts of melamine, 253 parts of 41.5% formalin, and 1.8 parts of triethylamine into a flask equipped with a thermometer, a condenser tube, a fractionating tube, and a stirrer, and pay attention to the heat release. Slowly raise the temperature to 100°C. After making it react at 100 degreeC under reflux for 2 hours, it heated up to 130 degreeC over 3 hours under normal pressure, removing water. Then, it was made to react under reflux for 2 hours, and then it heated up to 150 degreeC over 1 hour, removing water under normal pressure. Furthermore, it was made to react under reflux for 2 hours, and then it heated up to 180 degreeC over 2 hours, removing water under normal pressure. Next, unreacted p-tert-butylphenol was removed under reduced pressure to obtain a phenol resin (B-1). The GPC chart of gained phenolic resin (B-1) is shown in figure 1 . Based on the GPC chart, the content of the bifunctional compound represented by th...

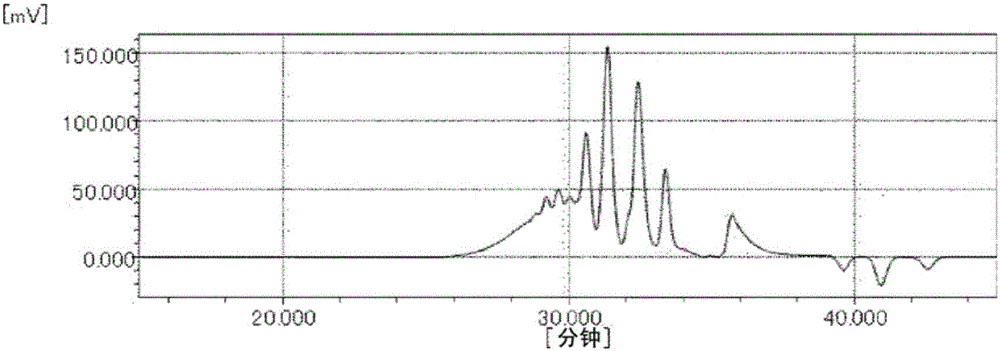

Synthetic example 2

[0161] In Synthesis Example 1, 438 parts of p-tert-butylphenol, 63 parts of melamine, 106 parts of 41.5% formalin, and 1.8 parts of triethylamine were changed, and the phenolic resin was obtained by the same operation as Synthesis Example 1. (B-2). The GPC chart of gained phenolic resin (B-2) is shown in figure 2 . Based on the GPC chart, the content of the bifunctional compound represented by the structural formula (III) was 8.4%, and Mw / Mn was 1.42.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com