Inclined slit based automatic focusing method and device

A technology of slits and tilt angles, which is applied in the field of semiconductor measurement, can solve problems such as difficulty in ensuring accuracy and difficulty in establishment, and achieves the effect of simple devices and structures and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The patent of the present invention proposes a new defocus detection and autofocus method and corresponding system. The autofocus method proposed in the patent of the present invention is not only not affected by fluctuations in light intensity of the light source, nor affected by differences in wafer pattern shape and reflectivity, but also simpler in optical structure than patent US4639587 and patent US7961763B2.

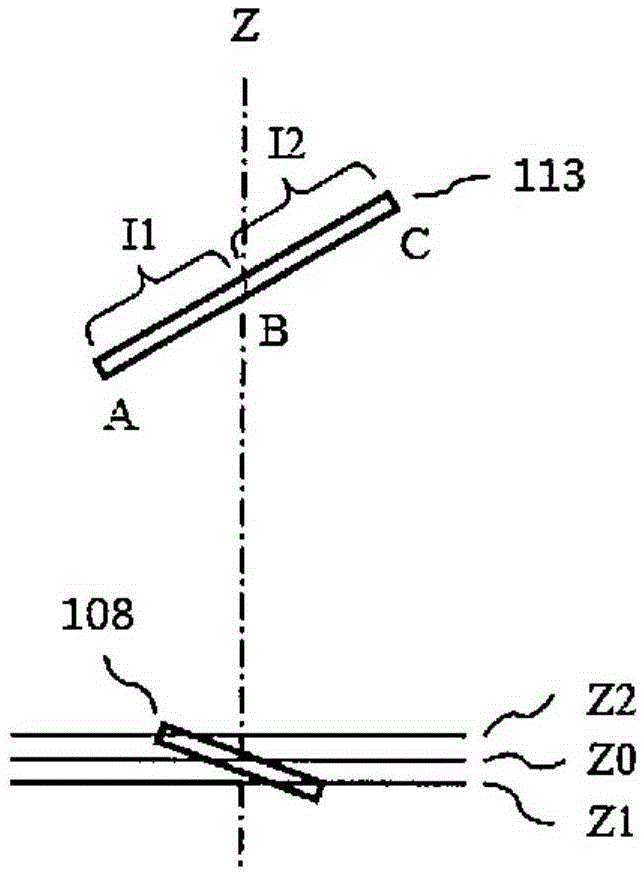

[0021] figure 1 An embodiment of the autofocus system of the present invention based on the oblique slit confocal method is shown. The hardware configuration of this embodiment is as follows: the illumination part is composed of a light source 101 and an illumination lens 102, and the light source 101 is an incoherent light source (such as LED). The oblique slit confocal imaging optical system consists of an illumination slit 103 , a lens 104 , a beam splitter 105 , an objective lens 107 , a lens 112 and a detection slit 113 . The arrangement of the lens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com