A kind of preparation method of double-coated diamond powder

A diamond powder and diamond technology, applied in metal processing equipment, coating, liquid chemical plating, etc., can solve the problems of Diamond/Cu composite material machining difficulties, limited part shape complexity, uneven density of formed blanks, etc. Achieve the effect of overcoming machining difficulties, high production efficiency and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

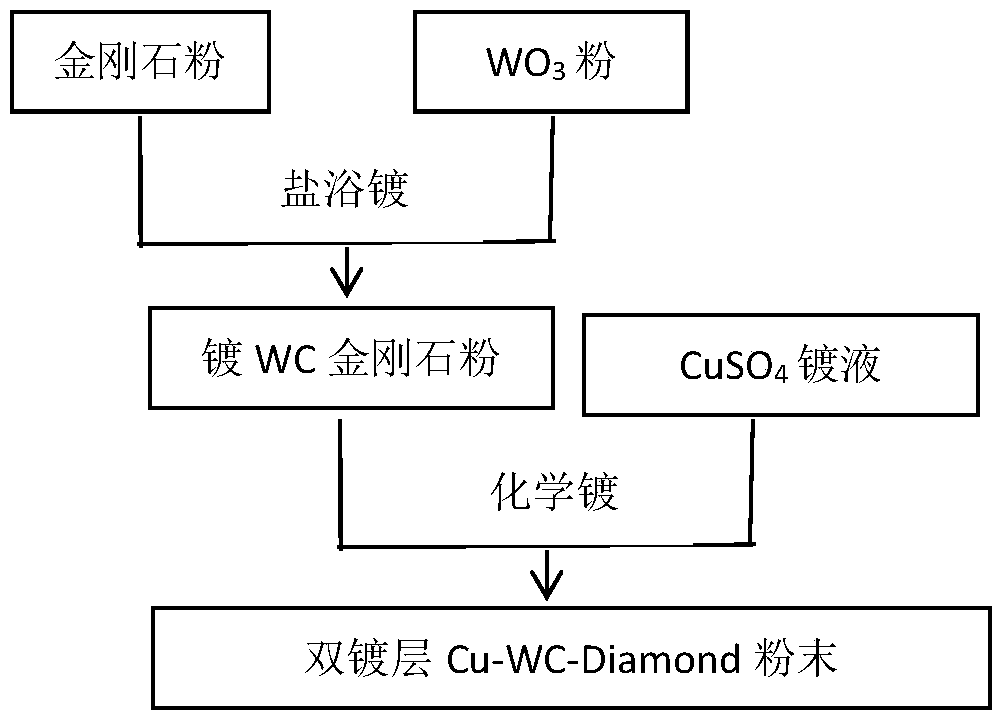

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: the Cu-WC-Diamond double-coated diamond powder that the volume fraction of the copper-coated layer is 30% is prepared

[0016] Step 1: Weigh 10g of MBD6 diamond powder with an average particle size of 80μm, WO 3 19.32g of powder, 30g of mixed salt NaCl-KCl (molar ratio NaCl:KCl=1:1), mixed with a powder mixer for 0.5h, and the powder loading was 53vol.%.

[0017] Step 2: Heat the above-mentioned mixed powder to 900° C. for 2 hours in a rapid heating tube electric furnace, and pass an Ar atmosphere for protection during this period. Put the reaction product in the tube furnace into a beaker filled with alcohol, and use an ultrasonic cleaner to vibrate and clean, dry and sieve to obtain diamond powder coated with a WC layer on the surface.

[0018] Step 3: Weigh 8g of diamond powder coated with WC layer and place it in 0.4L of SnCl 2 (30g / L) deionized aqueous solution for surface sensitization, and then placed in 0.4L of PdCl 2 (0.25g / L) deionized aqueous...

Embodiment 2

[0019] Embodiment 2: the Cu-WC-Diamond double-coated diamond powder that the volume fraction of the copper-coated layer is 40% is prepared

[0020] Step 1: Weigh 10g of MBD8 diamond powder with an average particle size of 100μm, WO 3 38.64g of powder, 40g of mixed salt NaCl-KCl (molar ratio NaCl:KCl=1:1), mixed for 1h with a powder mixer, and the powder loading was 63vol.%.

[0021] Step 2: Heat the above-mentioned mixed powder to 950° C. for 1 hour in a rapid heating tube electric furnace, during which an Ar atmosphere is introduced for protection. Put the reaction product in the tube furnace into a beaker filled with alcohol, and use an ultrasonic cleaner to vibrate and clean, dry and sieve to obtain diamond powder coated with a WC layer on the surface.

[0022] Step 3: Weigh 8g of diamond powder coated with WC layer and place it in 0.4L of SnCl 2 (30g / L) deionized aqueous solution for surface sensitization, and then placed in 0.4L of PdCl2 (0.25g / L) deionized aqueous solu...

Embodiment 3

[0023] Embodiment 3: the Cu-WC-Diamond double-coated diamond powder with 50% Cu-WC-Diamond volume fraction is prepared

[0024] Step 1: Weigh 10g of MBD10 diamond powder with an average particle size of 120μm, WO 3 57.96g of powder, 50g of mixed salt NaCl-KCl (molar ratio NaCl:KCl=1:1), mixed with a powder mixer for 3h, and the powder loading was 73vol.%.

[0025] Step 2: Heat the above-mentioned mixed powder to 1000° C. for 0.5 h in a rapid heating tube electric furnace, during which an Ar atmosphere is introduced for protection. Put the reaction product in the tube furnace into a beaker filled with alcohol, and use an ultrasonic cleaner to vibrate and clean, dry and sieve to obtain diamond powder coated with a WC layer on the surface.

[0026] Step 3: Weigh 8g of diamond powder coated with WC layer and place it in 0.4L of SnCl 2 (30g / L) deionized aqueous solution for surface sensitization, and then placed in 0.4L of PdCl 2 (0.25g / L) deionized aqueous solution for surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com