Preparation method of automobile bend pipe

A technology for pipe bends and automobiles, which is applied in the field of preparation of automobile bends, can solve the problems of poor bending performance, strength and brittleness of automobile bends, prone to cracking and damage, etc. Long life, combined with good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

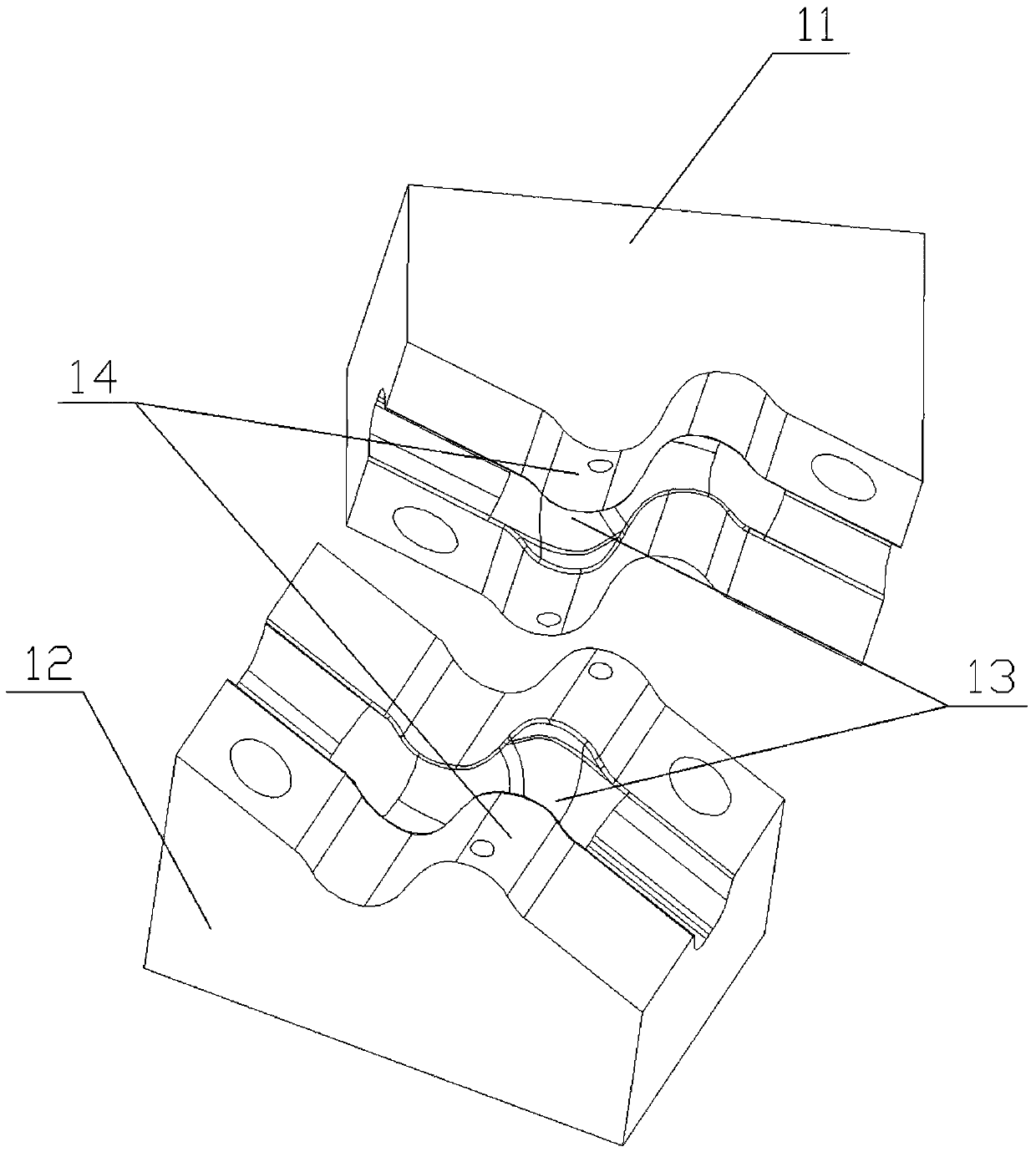

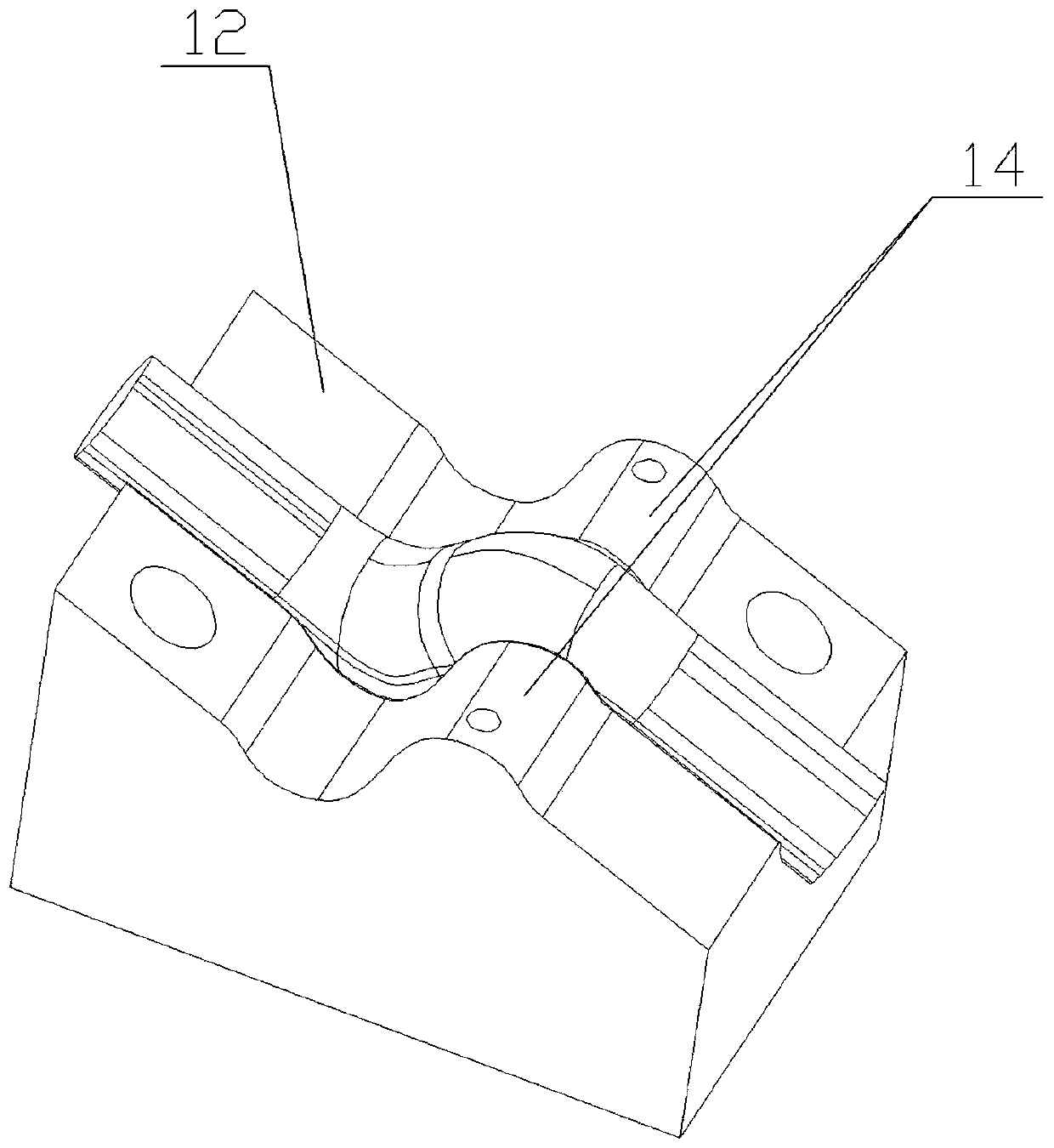

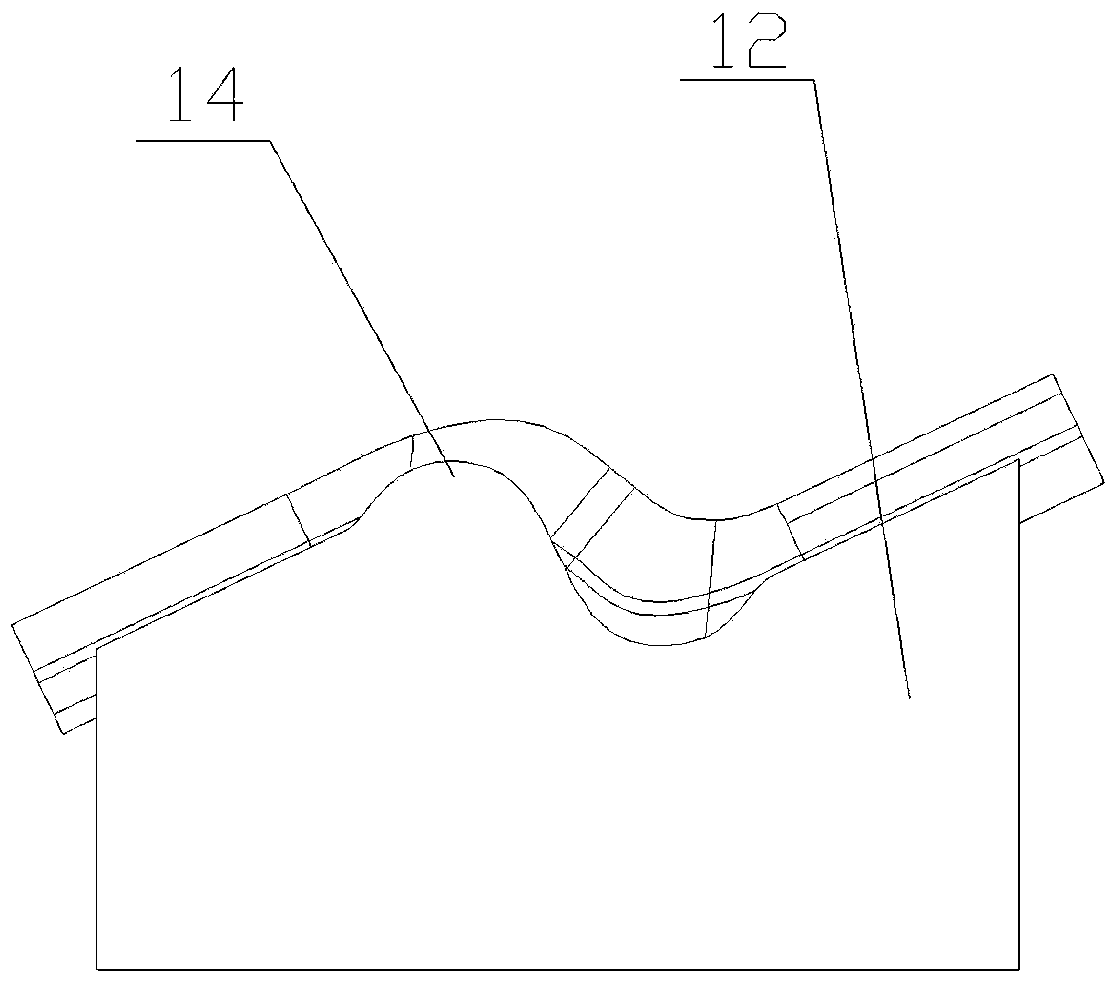

Image

Examples

Embodiment 1

[0034] 1. Selection of raw materials

[0035] The raw materials are high-purity lead, cadmium, bismuth, and tin metals, and the implementation standards of material composition are as follows.

[0036] Bismuth composition executive standard: GB / T 915-2001

[0037]

[0038] Tin composition executive standard: GT / T 728-1998

[0039]

[0040] Executive standard for lead composition: GB / T 469-2005

[0041]

[0042] Cadmium composition executive standard: YS / T 72-2005

[0043]

[0044] 2. The method for preparing the automobile elbow in this embodiment is as follows:

[0045] (1) quickly weigh each component of the following weight percentages: bismuth (Bi) 26%, lead (Pb) 40%, tin (Sn) 21%, cadmium (Cd) 13%, should minimize air and The contact time of raw materials is to avoid oxidation, and the raw materials are stored in sealed tanks for later use.

[0046] (2) Turn on the melting furnace, and set the temperature in the furnace to 620°C.

[0047] (3) Pour lead i...

Embodiment 2

[0055] The selection of raw material is with embodiment 1.

[0056] The preparation method of the present embodiment automobile bend pipe is as follows:

[0057](1) quickly weigh each component of the following weight percentages: bismuth (Bi) 10%, lead (Pb) 50%, tin (Sn) 25%, cadmium (Cd) 15%, or bismuth (Bi) 10%, Lead (Pb) 50%, tin (Sn) 24%, cadmium (Cd) 15%, copper (Cu) 0.5%, aluminum (Al) 0.5%, during operation, the contact time between air and raw materials should be minimized to avoid oxidation, The raw materials are stored in airtight jars for later use.

[0058] (2) Turn on the melting furnace, and set the temperature in the furnace to 600°C.

[0059] (3) Pour lead into the crucible in the smelting furnace first, then pour other components, stir evenly, and carry out smelting.

[0060] (4) When the temperature of the melting furnace rises to about 300°C, argon is introduced into the melting furnace so that the gas in the melting furnace is argon.

[0061] (5) Start...

Embodiment 3

[0067] The selection of raw material is with embodiment 1.

[0068] The preparation method of the present embodiment automobile bend pipe is as follows:

[0069] (1) quickly weigh each component of the following weight percentages: bismuth (Bi) 20%, lead (Pb) 45%, tin (Sn) 24%, cadmium (Cd) 11%, or bismuth (Bi) 20%, Lead (Pb) 45%, tin (Sn) 23%, cadmium (Cd) 11%, copper (Cu) 0.5%, aluminum (Al) 0.5%, during operation, the contact time between air and raw materials should be minimized to avoid oxidation, The raw materials are stored in airtight jars for later use.

[0070] (2) Turn on the melting furnace, and set the temperature in the furnace to 630°C.

[0071] (3) Pour lead into the crucible in the smelting furnace first, then pour other components, stir evenly, and carry out smelting.

[0072] (4) When the temperature of the melting furnace rises to about 300°C, argon is introduced into the melting furnace so that the gas in the melting furnace is argon.

[0073] (5) Star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com