Salt and alkali flooding resistant solid color primer and preparation method thereof

A primer and solid color technology, applied in the field of coatings, can solve the problems of loss of building support, prolongation of construction period, contradiction of construction time, etc., to improve the tear resistance of textured paper, shorten the construction period, and reduce the paint film. tearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

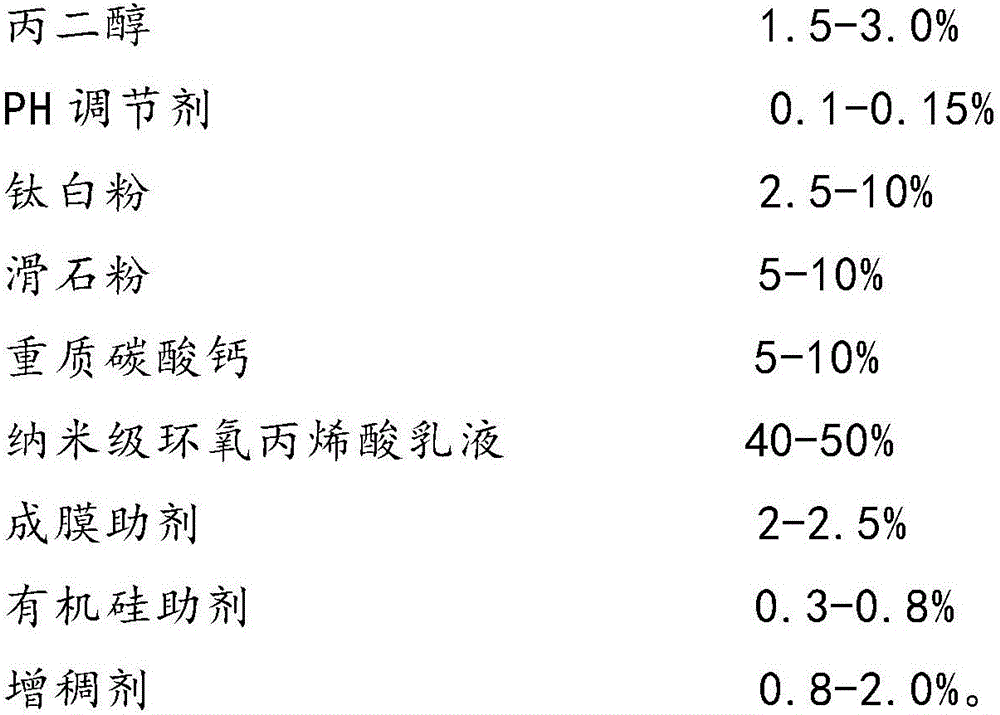

[0026] An embodiment of the anti-pan-saline solid color primer of the present invention, the components contained and the weight content of each component are:

[0027] Water 12.3%, dispersant 0.5%, wetting agent 0.2%, defoamer 0.3%, fungicide: 0.2%, antifungal agent 0.1%, propylene glycol: 2%, PH regulator 0.1%, titanium dioxide 10%, talc powder 10%, heavy calcium: 10%, nano-scale epoxy acrylic emulsion 50%, film-forming aid 2.5%, organosilicon additive 0.8%, thickener 1%.

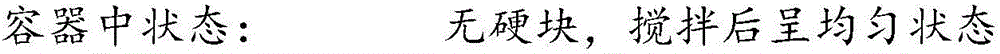

[0028] First, add water into the tank according to the formula given in the above examples, start the disperser, control the speed at 500 rpm, and slowly add dispersant, wetting agent, defoamer, bactericide, antifungal agent, propylene glycol in sequence , PH regulator, after adding, disperse for 10 minutes until mixed evenly; then, add titanium dioxide, talcum powder, heavy calcium carbonate in sequence, after adding, disperse at a high speed of 1200 rpm for 30 minutes, then reduce the speed to 700 Turn...

Embodiment 2

[0034] Another embodiment of the anti-pan-saline solid color primer of the present invention, the components contained and the weight content of each component are:

[0035] Water 18.3%, dispersant 0.5%, wetting agent 0.2%, defoamer 0.3%, fungicide 0.2%, antifungal agent 0.1%, propylene glycol 2%, PH regulator 0.1%, titanium dioxide 9%, talcum powder 10% %, 10% of heavy calcium carbonate, 45% of nano-scale epoxy acrylic emulsion, 2.3% of film-forming aids, 0.8% of organic silicon additives, and 1.2% of thickeners.

[0036]First, add water into the tank according to the formula given in the above examples, start the disperser, control the speed at 550 rpm, and slowly add dispersant, wetting agent, defoamer, bactericide, antifungal agent, propylene glycol in sequence , PH regulator, after adding, disperse for 8 minutes until mixed evenly; then, add titanium dioxide, talcum powder, heavy calcium carbonate in sequence, after adding, disperse at a high speed of 1300 rpm for 25 minu...

Embodiment 3

[0041] Yet another embodiment of the solid-color primer of anti-pan-saline-alkali of the present invention, the components that comprise and the weight content of each component are:

[0042] Water 24.7%, dispersant 0.5%, wetting agent 0.2%, defoamer 0.3%, fungicide 0.2%, antifungal agent 0.1%, propylene glycol 2%, PH regulator 0.1%, titanium dioxide 7%, talcum powder 10% %, 10% of heavy calcium carbonate, 40% of nano-scale epoxy acrylic emulsion, 2.1% of film-forming aids, 0.8% of organic silicon additives, and 2.0% of thickeners.

[0043] First, add water into the tank according to the formula given in the above examples, start the disperser, control the speed at 600 rpm, and slowly add dispersant, wetting agent, defoamer, bactericide, antifungal agent, propylene glycol in sequence , PH regulator, after adding, disperse for 5 minutes until mixed evenly; then, add titanium dioxide, talcum powder, heavy calcium carbonate in sequence, after adding, disperse at a high speed of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com