A kind of preparation method of low dielectric constant ordered porous polyimide film

A technology of polyimide film and low dielectric constant, applied in the field of preparation of ordered porous polyimide film with low dielectric constant, can solve the problem of SiO2 size, uniformity, dispersion control, air in PI film Problems such as uneven pore size distribution and affecting the mechanical properties of PI thin films can achieve the effect of reducing dielectric constant, linear thermal expansion coefficient and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

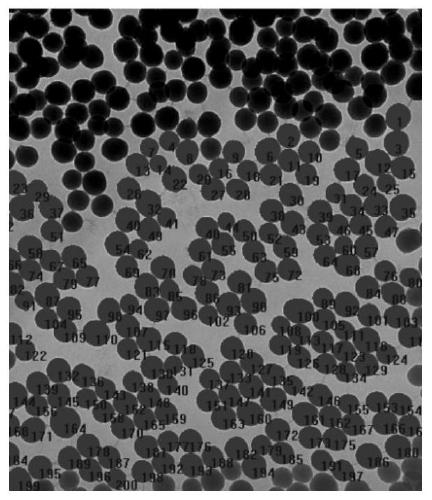

[0045] Silica microspheres with a diameter of 100 nm (named SiO 2 -100), prepared according to the following experimental steps:

[0046] In 90ml ethanol solution, add 28.5wt% concentrated ammonia water and deionized water in turn, keep the temperature at 25°C, and stir for 0.5-2h to ensure the uniform dispersion of the solute in the ethanol solution and the uniform temperature. Then add a certain amount of tetraethyl orthosilicate (TEOS) into the solution, and continue to stir rapidly for 6-12 hours to form a white translucent colloidal solution. The molar ratio of each substance in the synthetic mother liquor is TEOS:NH 3 :H 2 O:EtOH=1:4.4:16:100. After the stirring is completed, centrifuge with a high-speed centrifuge, and wash the precipitate with ethanol three times. Dry the obtained solid in an oven at 65-80°C for 12-24h, and grind it into powder to obtain SiO 2 -100. After testing, its diameter is 100nm.

Synthetic example 2-4

[0048] Silica microspheres with diameters of 200nm, 50nm and 30nm (named as SiO 2 -200, SiO 2 -50 and SiO 2 -30), prepared according to the experimental procedure in [Synthesis Example 1]; but the synthesis temperature in ethanol solution was changed to 20°C, 27°C and 35°C.

Synthetic example 5

[0050] Aminopropyl-modified silica microspheres with a diameter of 100 nm (named APro-SiO 2 -100), made of SiO 2 -100 was obtained by surface modification with amino functional groups. The specific processing steps are as follows:

[0051] In 60ml of toluene, add 1g of SiO synthesized in [Synthesis Example 1] 2 -100, stir well. Add aminopropyltrimethoxysilane (APS), concentrated hydrochloric acid and glacial acetic acid successively, and the molar ratio of each substance in the synthesis mother liquor is: SiO 2 :APS:HCl:HAc:H 2 O: Toluene=1:0.15:0.072:0.24:0.25:34; SiO 2 The molar mass of -100 is 60 g mol -1 . The above solution was stirred at reflux at 110°C for 12-24h. Then cool down to room temperature, centrifuge on a high-speed centrifuge, and wash the precipitate three times with ethanol. Dry the obtained solid in an oven at 65-80°C for 12-24h, and then age it in a muffle furnace at 250°C for 3-6h to obtain APro-SiO 2 -100. After testing, its diameter is 100nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com