Preparation method for solid polycarboxylic acid slump retaining agent

A technology of polycarboxylic acid and slump-retaining agent, which is applied in the field of preparation of solid polycarboxylic acid slump-retaining agent, can solve the problems of loss of polycarboxylic acid water-reducing agent, expensive equipment, influence of water-reducing effect, etc., and achieves good slump Degree retention, product state stability, increase the effect of steric hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

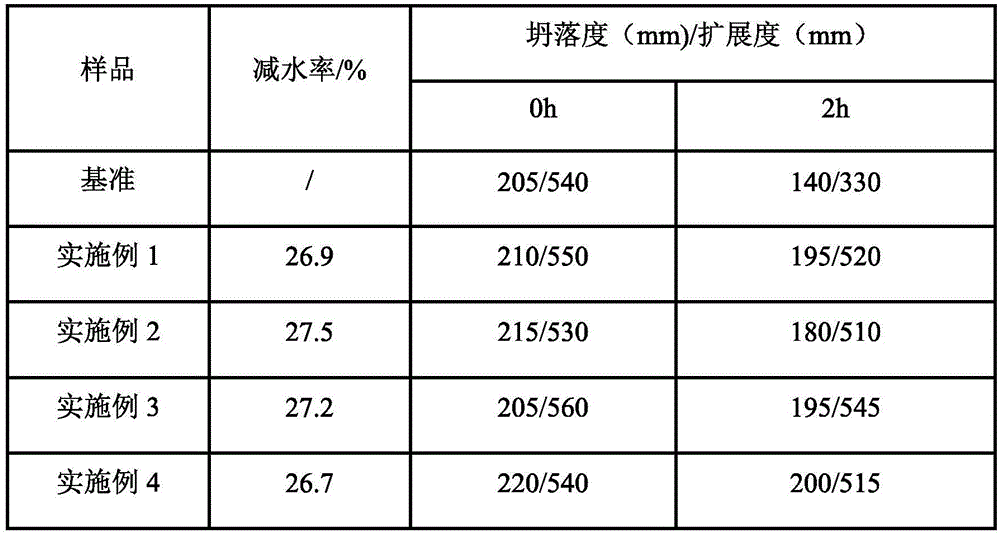

Examples

Embodiment 1

[0027] A solid polycarboxylate slump-retaining agent and a preparation method thereof, comprising the following steps:

[0028] (1) Add isopentenyl polyoxyethylene ether and cumenyl polyoxyethylene ether into the reaction kettle, raise the temperature to 60°C, make it in a molten state, and then add N,N-dimethylaniline at one time , and stir evenly;

[0029] (2) Add dropwise the first mixed solution consisting of acrylic acid, γ-(meth)acryloyloxypropyl trimethoxysilane and triallyl phosphate and The second mixed solution composed of dimethyl azodiisobutyrate, 3,6-dioxo-1,8-octanedithiol and acetone is dropped within 3 hours, and the reaction is continued for 1 hour;

[0030] (3) After the reaction, use a mechanical pump to evacuate for 10 minutes, the vacuum pressure is 0.01-0.05MPa, remove the acetone in the material obtained in step (2), and then use a condensing microtome to slice it to obtain white flake solid polycarboxylate Acid slump retaining agent, and packed by pac...

Embodiment 2

[0033] A solid polycarboxylate slump-retaining agent and a preparation method thereof, comprising the following steps:

[0034] (1) Add methallyl polyoxyethylene ether and cumenyl polyoxyethylene ether into the reaction kettle, and raise the temperature to 80°C. C, making it in a molten state, then adding N,N-diethylaniline in one go, and stirring evenly;

[0035] (2) To the material obtained in step (1), add dropwise the first compound composed of acrylic acid, γ-(meth)acryloyloxypropyltriethoxysilane and bistrimethylsilylated vinyl phosphate. The first mixed solution and the second mixed solution composed of cumene hydroperoxide, 3,6-dioxo-1,8-octanedithiol and n-hexane are dripped within 3 hours, and the reaction is continued for 1 hour;

[0036] (3) After the reaction is over, use a mechanical pump to vacuumize for 10 minutes, and the vacuum pressure is 0.01 to 0.05 MPa to remove the n-hexane in the material obtained in step (2), and then use a condensing microtome to sli...

Embodiment 3

[0039] A solid polycarboxylate slump-retaining agent and a preparation method thereof, comprising the following steps:

[0040] (1) Add methallyl polyoxyethylene ether and cumenyl polyoxyethylene ether into the reaction kettle, raise the temperature to 60°C, make it in a molten state, and then add N,N-diethyl aniline, and stir well;

[0041] (2) Add dropwise the first mixed solution consisting of acrylic acid, γ-(meth)acryloyloxypropyl triethoxysilane and 6 triallyl phosphate respectively in the material obtained in step (1) and The second mixed solution composed of dicyclohexyl peroxydicarbonate, 3,6-dioxo-1,8-octanedithiol, and carbon tetrachloride was dropped within 4 hours, and the reaction was continued for 1 hour;

[0042] (3) After the reaction finishes, adopt mechanical pump to vacuumize 10min, and vacuum pressure is 0.01~0.05MPa, removes the carbon tetrachloride in the material gained in step (2), adopts condensing microtome to slice then, promptly obtains the white ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com