Atom transfer radical polymerization method utilizing low temperature eutectic melt effect

A low-temperature eutectic and atom transfer technology, applied in the field of polymer active polymerization, can solve the problems of high toxicity and expensive ligands, and achieve the effects of reducing viscosity, reducing reaction heat, and simplifying post-treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

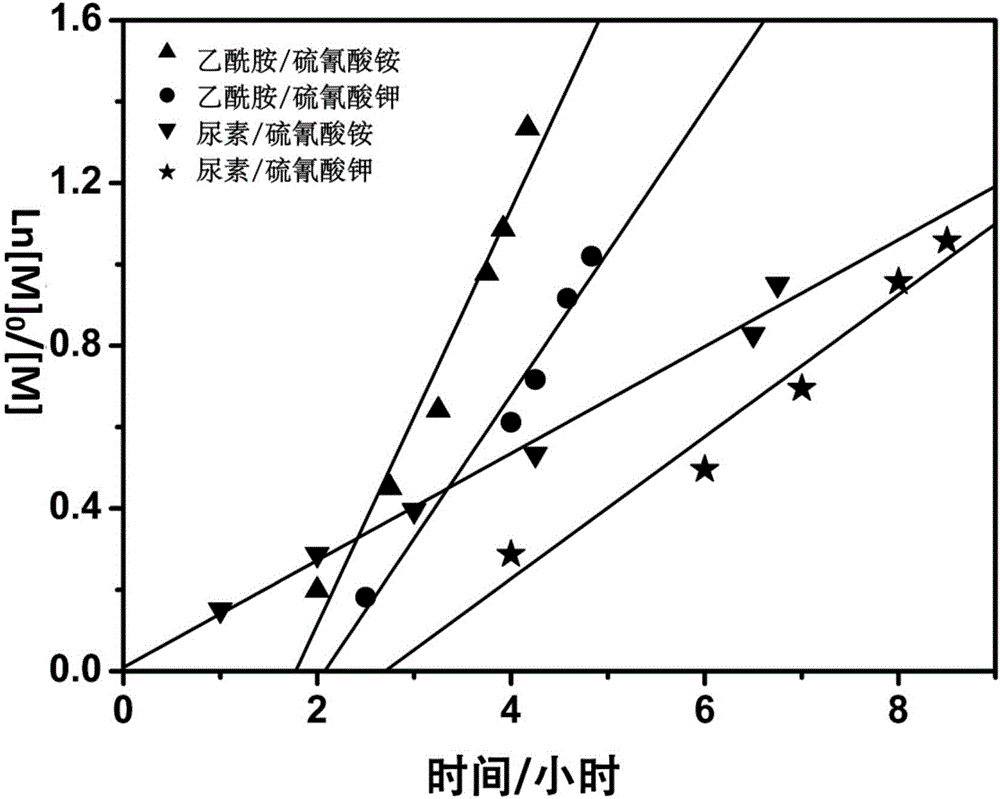

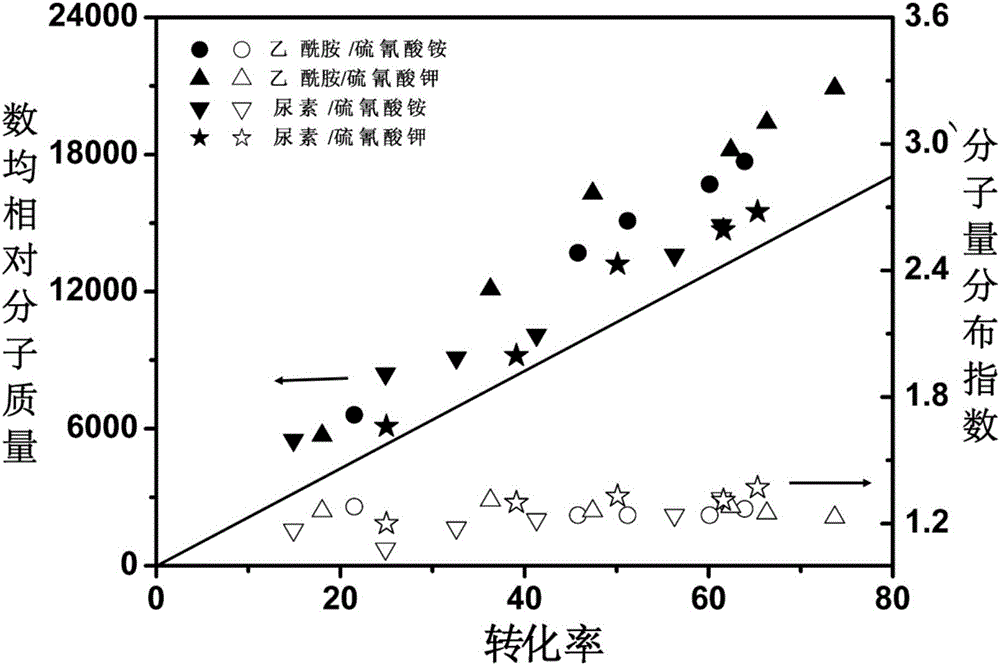

[0041] After the purification of methyl methacrylate monomer and ethyl 2-bromophenylacetate initiator, carry out the preparation of polymerization reaction components, methyl methacrylate, ethyl 2-bromophenylacetate, ferrous bromide (low valence state transition metal catalyst) molar ratio is 100:1:1, methyl methacrylate and low-temperature eutectic (low-temperature eutectic are respectively four groups, namely, acetamide-ammonium thiocyanate low-temperature eutectic, ethyl methacrylate The volume ratio of amide-potassium thiocyanate low-temperature eutectic, urea-ammonium thiocyanate low-temperature eutectic, urea-potassium thiocyanate low-temperature eutectic) is 100:1. The preparation process is as follows: weigh 0.122 grams of ferrous bromide in the glove box and put it into an eggplant-shaped bottle, add 6 ml of methyl methacrylate monomer into the eggplant-shaped bottle, and stir magnetically for 20 minutes to obtain a pre-reaction mixture. liquid.

[0042] Transfer the...

Embodiment 2

[0045] After the purification of methyl methacrylate monomer and ethyl 2-bromophenylacetate initiator, carry out the preparation of polymerization reaction components, methyl methacrylate, ethyl 2-bromophenylacetate, ferrous bromide (low valence state transition metal catalyst) molar ratio is 200:1:1, the volume ratio of methyl methacrylate and low-temperature eutectic is 3:1 (low-temperature eutectic is divided into three kinds, namely caprolactam-acetamide low-temperature eutectic body, acetamide-urea low-temperature eutectic, caprolactam-urea low-temperature eutectic). The preparation process is as follows: weigh 0.061 g of ferrous bromide in the glove box and put it into an eggplant-shaped bottle, add 6 ml of methyl methacrylate monomer into the eggplant-shaped bottle, and stir magnetically for 20 minutes to obtain a pre-reaction mixture liquid.

[0046] The pre-reaction mixture in the eggplant-shaped bottle was transferred to a heating device, and the reaction temperatur...

Embodiment 3

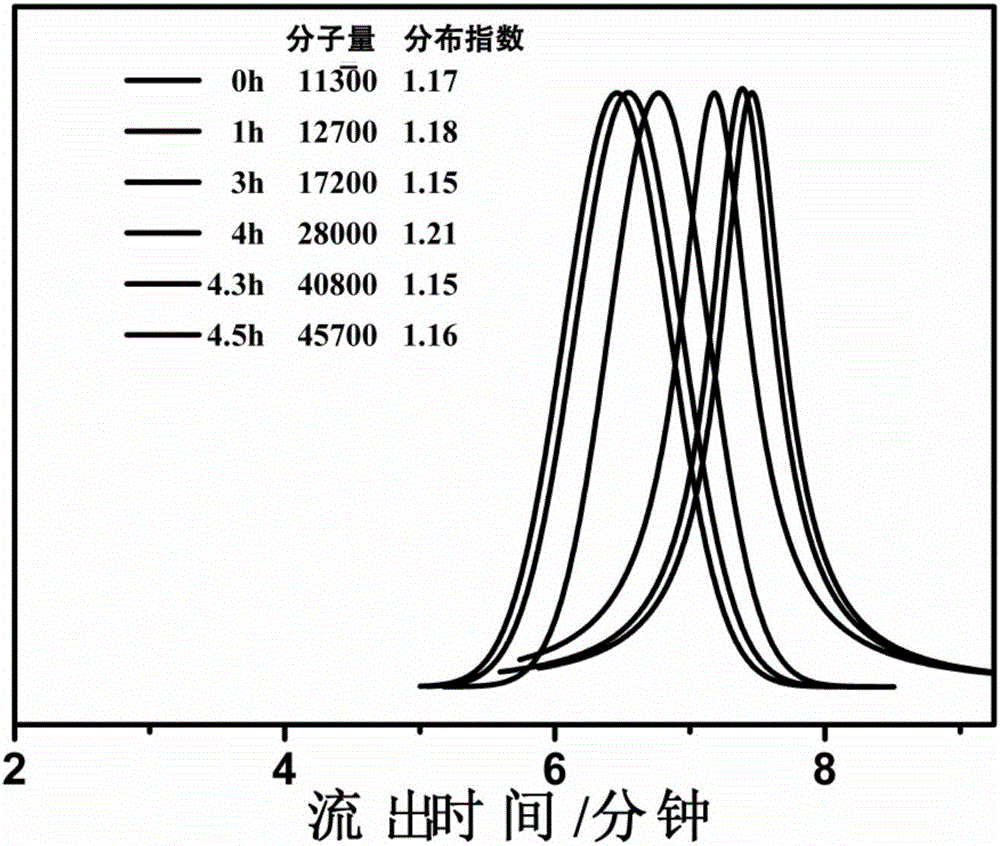

[0048] After purifying the n-butyl methacrylate monomer and ethyl 2-bromophenylacetate initiator, prepare the polymerization reaction components, n-butyl methacrylate, ethyl 2-bromophenylacetate, ferrous bromide (Low-valent transition metal catalyst) The molar ratio is 50:1:1, and the volume ratio of methyl methacrylate and acetamide-potassium thiocyanate low-temperature eutectic is 50:1. The preparation process is as follows: weigh 0.122 grams of ferrous bromide in the glove box and put it into an eggplant-shaped bottle, take 4 ml of n-butyl methacrylate monomer and add it to the eggplant-shaped bottle, and stir magnetically for 20 minutes to obtain a pre-reaction Mixture.

[0049] Transfer the pre-reaction mixture in the eggplant-shaped bottle to a heating device, control the reaction temperature to 60°C, heat and stir for five minutes, then add 30 microliters of acetamide-potassium thiocyanate low-temperature eutectic and 49.5 microliters of 2-bromo Ethyl phenylacetate sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com