Method for preparing porous silicon carbide ceramic by discharging plasma sintering method

A porous silicon carbide, discharge plasma technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of complex preparation methods and different experimental conclusions, and achieve the effect of simplifying the preparation process, uniform pore distribution, and three-dimensional interconnection of pore distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

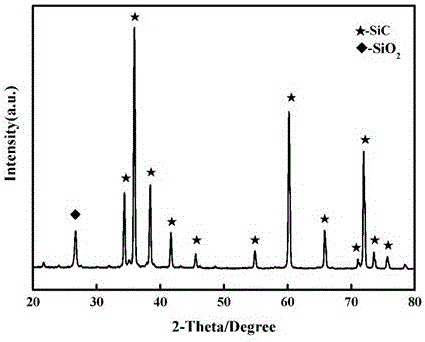

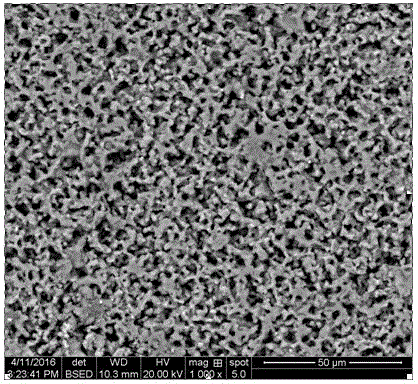

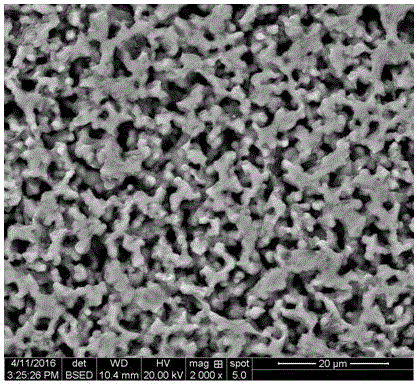

[0030] Mix silicon carbide powder (average particle size 0.8 μm) and deionized water at a mass ratio of 1:20, perform magnetic stirring and ultrasonic dispersion at room temperature for 20 minutes to obtain a mixed slurry; then put the mixed slurry into a polymer Ball mill in a tetrafluoroethylene tank for 12 hours, the ball milling medium is silicon carbide balls, and the dispersant is deionized water; the slurry after ball milling is placed in a vacuum drying oven and dried at 80°C for 12 hours to obtain silicon carbide powder; the obtained powder After being ground and passed through a 100-mesh sieve, it is aged in the natural environment for 12 hours; then the aged powder is put into a mold with a diameter of 30mm, and the temperature is 1800°C under vacuum conditions (heating rate: before 1600°C is 100°C / min, 1600~1800°C heating rate is 30°C / min), sintering at 50MPa for 5min to obtain the product;

[0031] The product has a directional and interconnected pore structure, a...

Embodiment 2

[0033] Mix silicon carbide powder (average particle size 0.8 μm) and deionized water at a mass ratio of 1:20, perform magnetic stirring and ultrasonic dispersion at room temperature for 20 minutes to obtain a mixed slurry; then put the mixed slurry into a polymer Ball mill in a tetrafluoroethylene tank for 12 hours, the ball milling medium is silicon carbide balls, and the dispersant is deionized water; the slurry after ball milling is placed in a vacuum drying oven and dried at 80°C for 12 hours to obtain silicon carbide powder; the obtained powder After grinding and passing through a 100-mesh sieve, it was aged in the natural environment for 12 hours; then the aged powder was put into a mold with a diameter of 30mm, and the temperature was 1800°C under vacuum conditions (the heating rate was the same as in Example 1). , Sintering at 30MPa for 5 minutes to obtain the product; the product has a directional and interconnected pore structure, and the silicon carbide particles are...

Embodiment 3

[0035] Mix silicon carbide powder (average particle size 0.8 μm) and deionized water at a mass ratio of 1:20, perform magnetic stirring and ultrasonic dispersion at room temperature for 20 minutes to obtain a mixed slurry; then put the mixed slurry into a polymer Ball mill in a tetrafluoroethylene tank for 12 hours, the ball milling medium is silicon carbide balls, and the dispersant is deionized water; the slurry after ball milling is put into a vacuum drying oven and dried at 100°C for 6 hours to obtain silicon carbide powder; the obtained powder After grinding and passing through a 100-mesh sieve, it was aged in the natural environment for 12 hours; then the aged powder was put into a mold with a diameter of 30mm, and the temperature was 1800°C under vacuum conditions (the heating rate was the same as in Example 1). , Sintering for 10 minutes under the condition of 20MPa to obtain the product; the product has a directional and interconnected pore structure, and the silicon c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com