Trickling filtration technique and device for effectively removing nitrate nitrogen in high-nitrogen low-carbon environment

A trickling filtration and environmental technology, applied in the field of trickling filtration technology for effectively removing nitrate and its device, can solve the problems of inability to purify sewage, high soil utilization rate, low purification efficiency, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

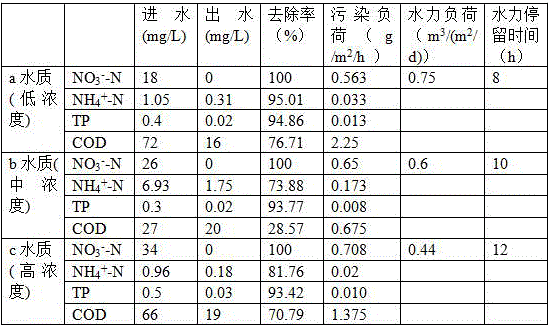

[0041] Water quality a, water quality b, and water quality c were obtained from different concentrations of Dianchi Lake sewage. The water temperature was 8-18 degrees Celsius, the hydraulic retention time was HRT 8h, and the sulfur autotrophic denitrification process was started for water quality a, water quality b, and water quality c. . The water inflow is 15L / d, and the removal rate of nitrate nitrogen in water quality a, water quality b, and water quality c reaches more than 80%. Soak sulfur and limestone in activated sludge, inoculate, and then pack columns to dynamically hang film on the reactor. domesticated.

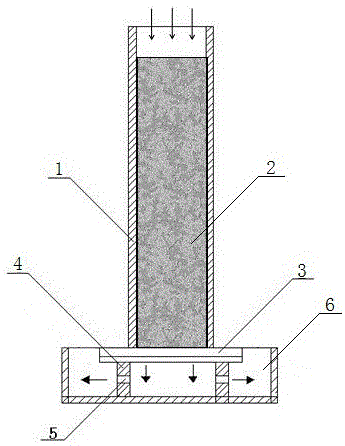

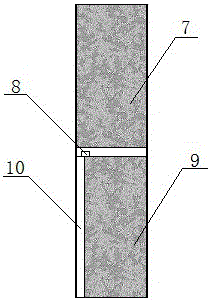

[0042] First, the sewage with a nitrate nitrogen content greater than 25mg / L and a carbon-nitrogen ratio less than 4:1 is lifted to the top of the trickling filter to distribute water evenly. The treated water temperature is 8°C, and the height of the filter layer is 1.5 meters. The filter layer is filled with sulfur mixed with limestone. Filler, wherein the vo...

Embodiment 2

[0047] The shallow groundwater in the greenhouse vegetable planting area is taken, the nitrate nitrogen content is greater than 25 mg / L, and the carbon-nitrogen ratio is less than 4:1. The vegetables planted in the greenhouse vegetable planting area are lettuce and cabbage. First, lift the sewage to the top of the trickling filter to distribute water evenly. The temperature of the treated water is 10°C. The height of the filter layer is 1.2 meters. The filter layer is filled with mixed fillers of sulfur and limestone. The volume ratio of sulfur to limestone is 1:2. Sulfur is in the form of yellow flakes with a thickness of 0.5mm and a particle size of 3mm. The limestone is granular and has a particle size of 5mm. Under anoxic conditions, the sewage is permeated through the filter layer, and finally the bottom of the filter material is flooded with water. The hydraulic load of the trickling filter device is 0.44 cubic meters / square meter day, and the hydraulic retention time is ...

Embodiment 3

[0050] The shallow groundwater in the greenhouse vegetable planting area is taken, the nitrate nitrogen content is greater than 25mg / L, and the carbon-nitrogen ratio is less than 4:1. The vegetables planted in the greenhouse vegetable planting area are bitter cabbage and water spinach. First, lift the sewage to the top of the trickling filter to distribute water evenly. The temperature of the treated water is 12°C. The height of the filter layer is 1.5 meters. The filter layer is filled with mixed fillers of sulfur and limestone. The volume ratio of sulfur and limestone is 1:2. Sulfur is in the form of yellow flakes with a thickness of 1.2 mm and a particle size of 8 mm. The limestone is granular and has a particle size of 10 mm. Under anoxic conditions, the sewage permeates the filter layer, and finally submerges water at the bottom of the filter material. The hydraulic load of the trickling filter device is 0.75 cubic meters / square meter day, and the hydraulic retention time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com