Handrail of buffer guardrail

A technology of railings and guardrails, applied in the directions of roads, road safety devices, roads, etc., can solve the problems of inability to play a supporting role, and achieve the effect of simple structure, easy transportation, and alleviation of handling problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

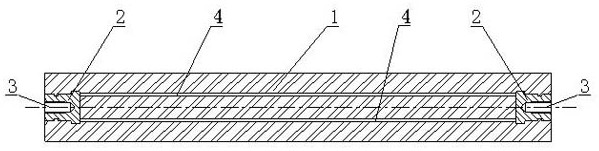

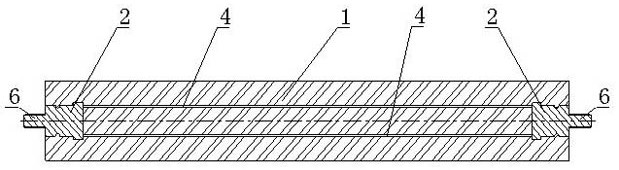

[0029] like figure 1 As shown, a railing for a buffer guardrail includes a railing body 1, two ends of the railing body 1 are provided with an end connecting sleeve 2, and the outer end of the end connecting sleeve 2 is provided with a threaded connection unit. The threaded connection unit is to connect the internal threaded hole 3, such as figure 2 As shown, the threaded connection unit can also be a connection stud 6 with external threads. The other ends of the two end connecting sleeves 2 are connected by reinforcing ribs 4 . The railing body 1 is made of waste rubber. The waste rubber can be prepared by putting the waste rubber into the crusher in a formula amount, crushing it into waste rubber particles with a diameter of 1-4mm, and then mixing with the curing agent and anti-aging agent, and then curing. production. This solves the problem of recycling waste rubber, especially waste tires; the cross section of the railing body 1 can be circular, square or hexagonal. ...

Embodiment 2

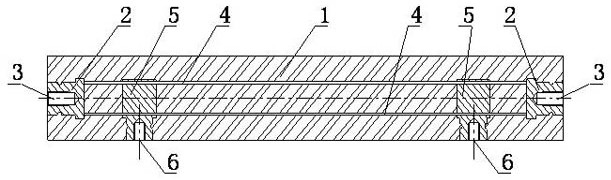

[0032] like image 3 As shown, on the basis of the above-mentioned embodiment 1, a middle connecting sleeve 5 is provided between the two end connecting sleeves 2 , and the two end connecting sleeves 2 and the middle connecting sleeve 5 are connected by reinforcing ribs 4 . One end of the middle connecting sleeve 5 is provided with a threaded connection unit, and the axis of the threaded connection unit is perpendicular to the centerline of the railing body 1 . The number of the middle connecting sleeves 5 is 2-15. The threaded connection unit at the outer end of the end connecting sleeve 2 and the threaded connecting unit at one end of the middle connecting sleeve 5 are both connecting internal threaded holes 3 . like Figure 4 As shown, the threaded connection unit at the outer end of the end connection sleeve 2 and the threaded connection unit at one end of the middle connection sleeve 5 are connection studs 6 .

[0033] The railing described in Embodiment 2 can be used ...

Embodiment 3

[0035] like Figure 5 As shown, on the basis of the above-mentioned embodiment 2, both ends of the middle connecting sleeve 5 are provided with threaded connection units, and the threaded connection units are connecting internal threaded holes 3 . like Image 6 As shown, the threaded connection unit can also be a connection stud 6 with external threads. At this time, this embodiment can only be used as an intermediate column, and both sides of the column can be connected with the upper beam and the lower beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com