Preparation method of amorphous monodisperse nano silicon dioxide powder with controllable granularity

A nano-silicon dioxide and silicon dioxide technology, applied in the direction of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve problems such as difficult dispersion, failure to meet the requirements of nano-scale products, poor compatibility, etc., and achieve production The effect of short cycle time, low production cost, and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

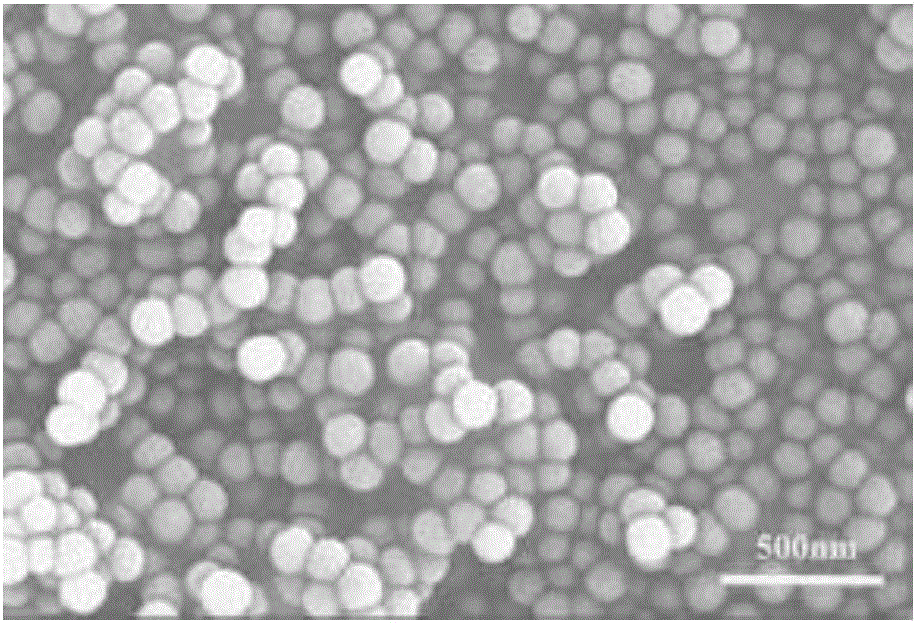

[0031] At a constant temperature of 25°C, add 0.1g sodium dodecylsulfonate, 2.5mL ammonia water and 15mL deionized water to 50mL methanol solvent to prepare solution A; add 5mL MTMS to 50mL methanol solvent to prepare solution B Stir the above two solutions for 1 hour respectively, after mixing evenly, slowly add solution B dropwise to solution A and stir for 10 hours to form a silica sol; age the obtained silica sol in air for 24 hours to obtain a gel , dried in a freeze dryer at -40°C for 48h; the obtained product was mixed with 20mL of ethanol to form a slurry, ball milled for 5h, and dried in an oven at 50°C for 5h to finally obtain white amorphous monodisperse nano-silica with a particle size of 100nm Powder. Utilize scanning electron microscope to observe the dispersion situation of product powder, see figure 1 , indicating that the silicon dioxide silicon dioxide powder has good dispersibility.

Embodiment 2

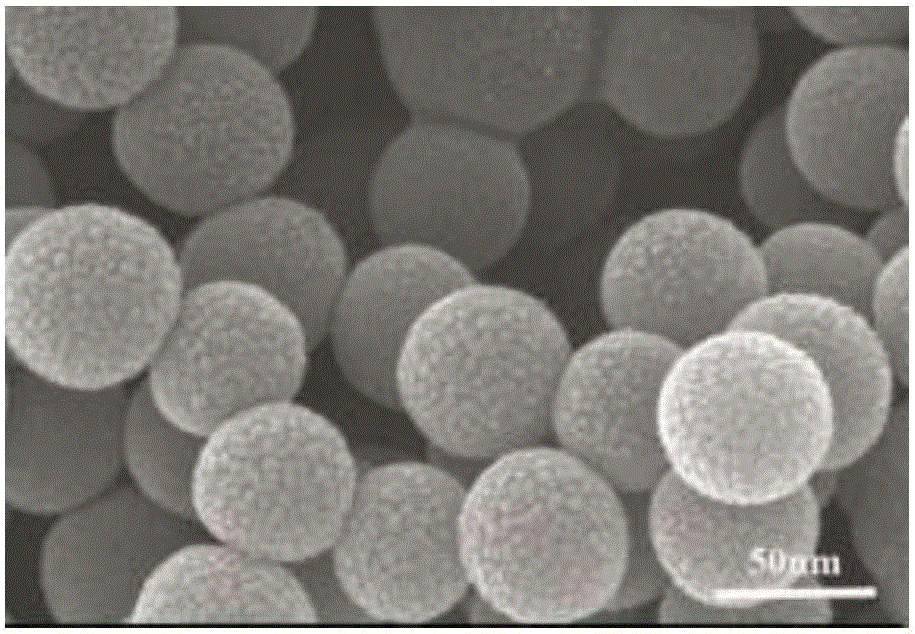

[0033] At a constant temperature of 35°C, add 0.5mL polyethylene glycol, 2.5mL ammonia water and 10mL deionized water to 50mL methanol solvent to prepare solution A; add 5mL TMOS to 50mL methanol solvent to prepare solution B; The two solutions were stirred for 1 hour respectively, and after mixing evenly, solution B was slowly added dropwise to solution A and stirred for 10 hours to form a silica sol; the obtained silica sol was aged in the air for 24 hours to obtain a gel, which was then frozen Dry in a dryer at -40°C for 48h; mix the obtained product with 20mL of ethanol to form a slurry, ball mill for 5h, and dry in an oven at 50°C for 5h to finally obtain a white amorphous monodisperse nano-silica powder with a particle size of 50nm. Utilize scanning electron microscope to observe the dispersion situation of product powder, see figure 2 , indicating that the silica powder has good dispersibility.

Embodiment 3

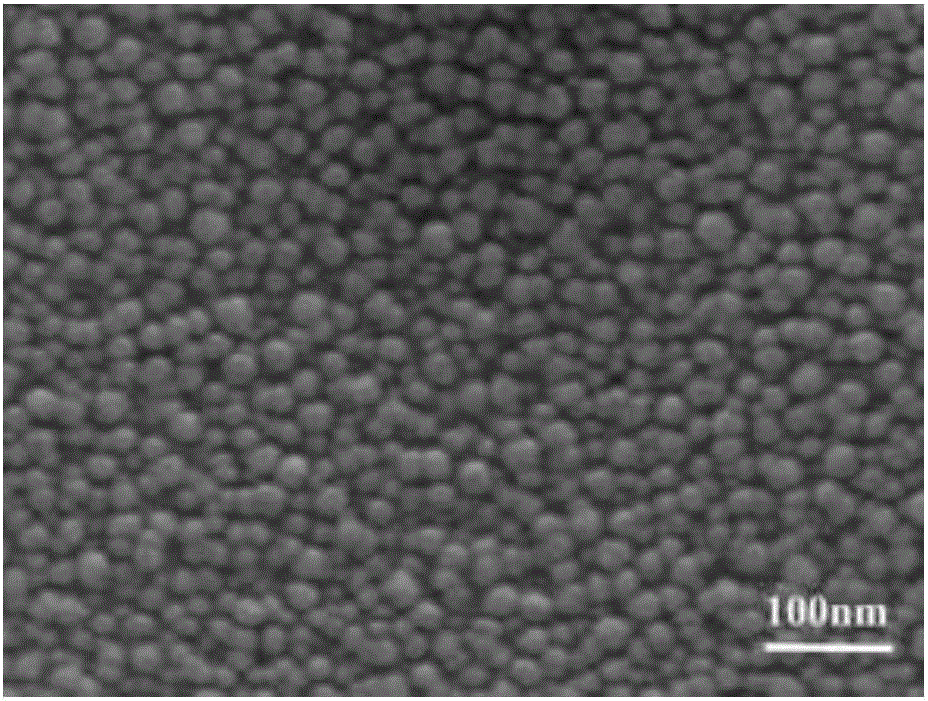

[0035] At a constant temperature of 45°C, add 0.5mL CO-520, 2.5mL ammonia water and 3mL deionized water to 50mL methanol solvent to prepare solution A; add 5mL TEOS to 50mL methanol solvent to prepare solution B; The two solutions were stirred for 1 hour respectively, and after mixing evenly, solution B was slowly added dropwise to solution A and stirred for 10 hours to form a silica sol; the obtained silica sol was aged in the air for 24 hours to obtain a gel, which was then freeze-dried Dry in a machine at -40°C for 48h; mix the obtained product with 20mL of ethanol to form a slurry, ball mill for 5h, and dry in an oven at 50°C for 5h to finally obtain a white amorphous monodisperse nano-silica powder with a particle size of 30nm. Utilize scanning electron microscope to observe the dispersion situation of product powder, see image 3 , indicating that the silica powder has good dispersibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com