Device and method for fast drying after plastic extrusion pelletizing

An extrusion granulation and rapid drying technology, which is applied in the direction of drying gas arrangement, granular material drying, heating device, etc., can solve the problems of high energy consumption, long drying time, cross-linking affecting the quality of raw materials and products, etc., and achieve drying time Short, good drying performance, stable quality control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

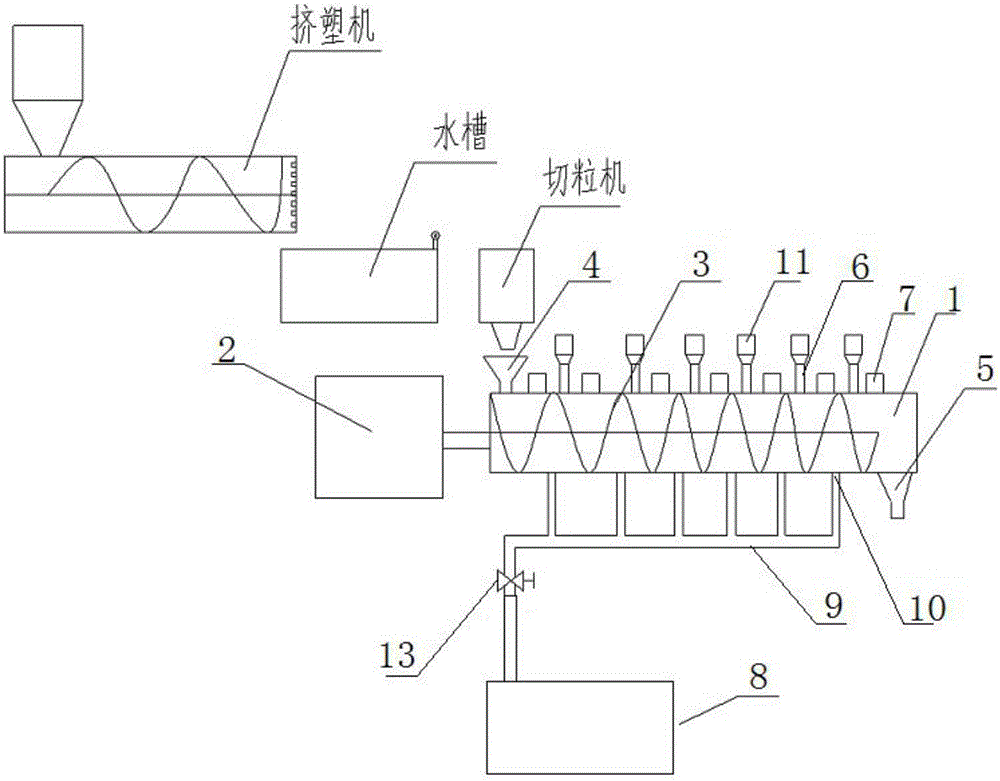

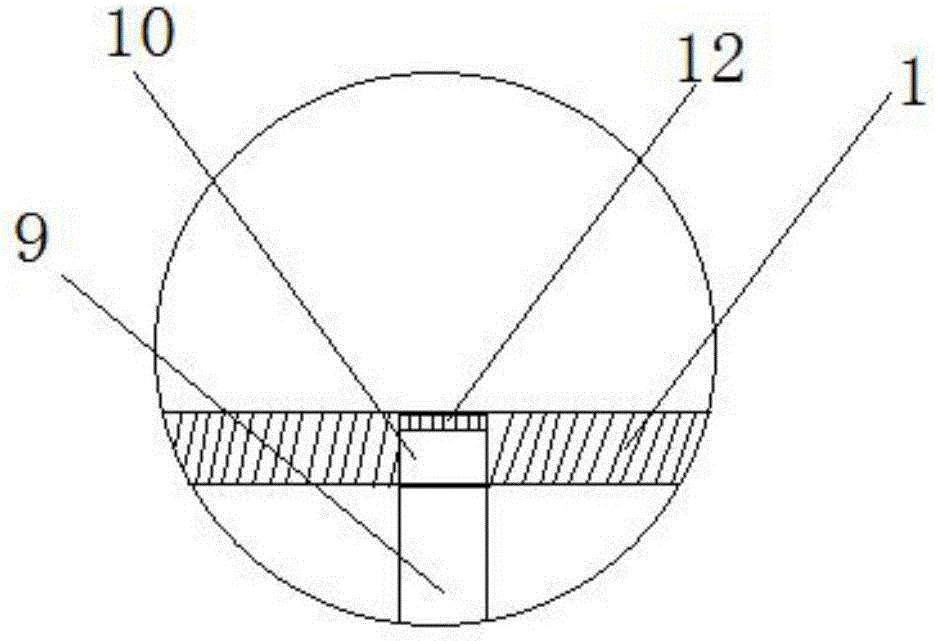

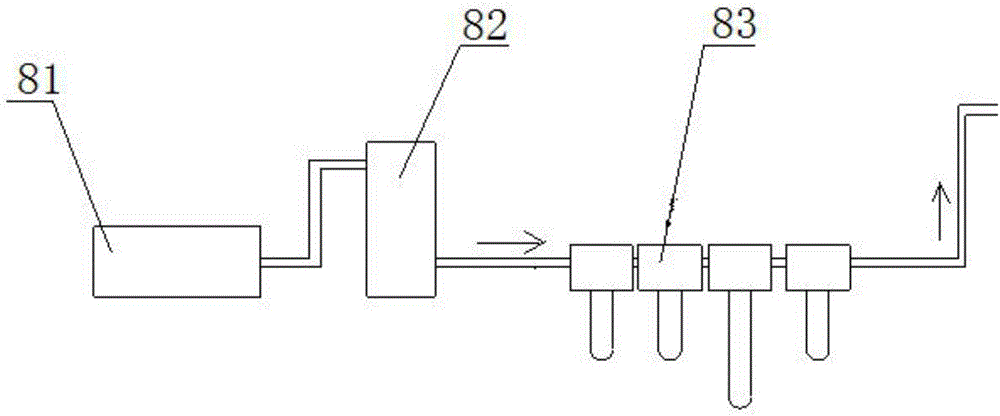

[0032] figure 1 with 2 It shows a rapid drying device after plastic extrusion and granulation of the present invention, including a drying chamber 1, a driving device 2, a screw conveying blade 3, a feed inlet hopper 4, a drying terminal outlet 5, an air outlet pipe 6, Microwave source 7, dry air preparation device 8, air supply pipe 9 and air supply port 10. The drying chamber 1 is a closed cylinder with both ends arranged horizontally. Specifically, the drying chamber 1 can be made of stainless steel plate into a cylindrical shape. And weld the sealing plate of the same material at both ends to form the drying chamber 1 . The drying chamber 1 is provided with a screw conveying blade 3, and the drying chamber 1 is provided with a drive device 2 for driving the spiral conveying blade 3 to rotate. Specifically, the drive device 2 includes a motor and a reducer, and is powered by an external power supply to generate power. , through the transmission connection with the screw c...

Embodiment 2

[0039] Such as figure 1 A method for drying silane cross-linked polyethylene particles using a quick drying device after plastic extrusion and granulation, comprising the following steps:

[0040] (1) The silane cross-linked polyethylene passes through an extruder into a strand, first passes through a cooling water tank to cool down, and then is cut into small particles by a pelletizer;

[0041] (2) The granulated pellets after granulation are transported to the feed inlet hopper 4 of the microwave rapid drying device through a blower fan, and further enter into the drying chamber 1;

[0042] (3) The driving device 2 drives the screw conveying blade 3 to rotate, so that the particles move from the feed inlet hopper 4 to the drying terminal outlet 5;

[0043] (4) Turn on the microwave source 7 to heat the particles, and turn on the control valve 13 on the dry air production device 8 to supply dry air to the drying chamber 1 .

[0044] Preferably, the air produced by the dry a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com