Manufacturing method of stainless steel jet nozzle of gas stove

A manufacturing method, stainless steel technology, applied in combustion methods, burners, heating fuels, etc., can solve problems such as affecting the performance of gas stove nozzles, increasing carbon monoxide emissions, and inability to complete drilling nozzle holes, achieving improved surface Finish, improve quality, prevent breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

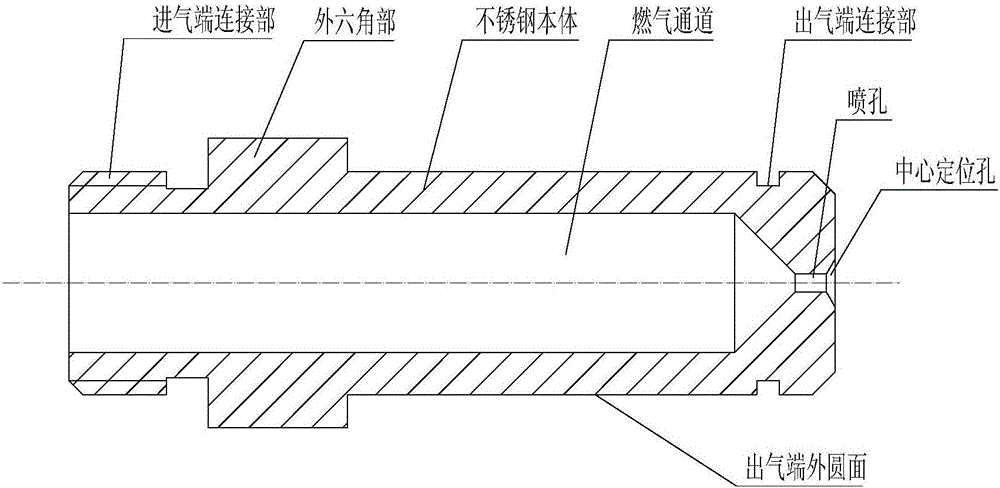

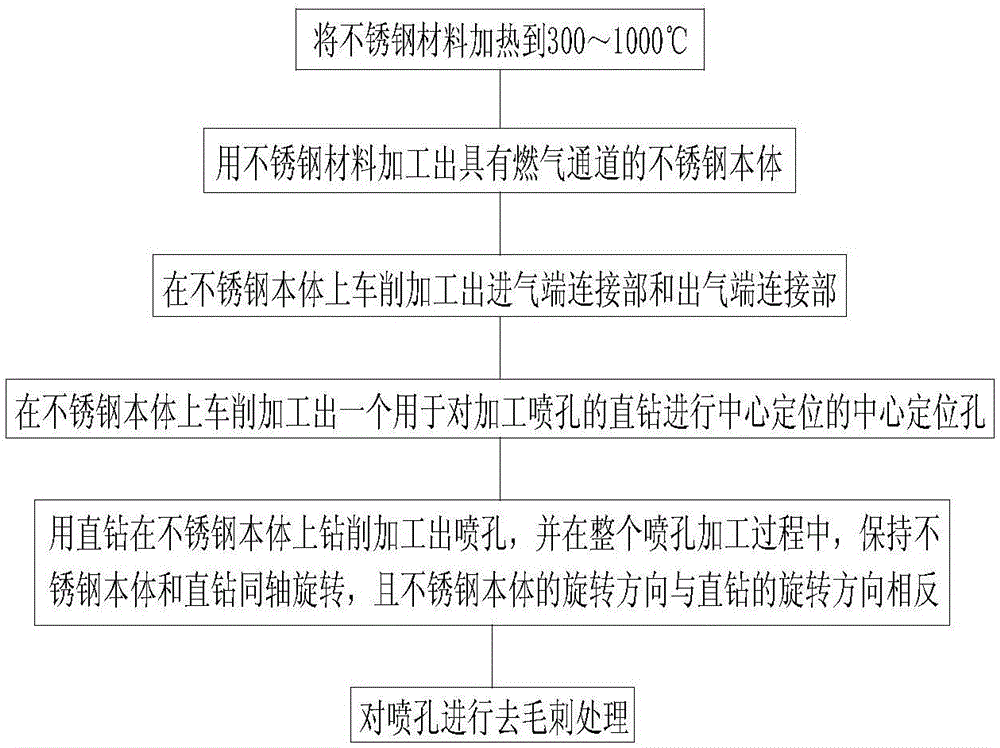

[0041] Such as figure 1 and image 3 shown to manufacture figure 1 Taking the stainless steel nozzle of the gas stove as an example, the manufacturing method of the stainless steel nozzle of the gas stove of the present invention comprises the following steps:

[0042] Use an electric heater to heat the stainless steel material to 300-1000°C. The specific heating temperature can be determined according to different types of stainless steel materials. The main purpose of this step is to soften the stainless steel material so as to greatly reduce the impact on the stainless steel material. The wear of the extrusion die improves the service life of the extrusion die. Of course, the temperature of the stainless steel material should not be too high to avoid oxidation of the stainless steel material at high temperature. The purpose of setting the heating upper limit temperature in this step is also based on this;

[0043] The stainless steel nozzle body with gas channel is proces...

Embodiment 2

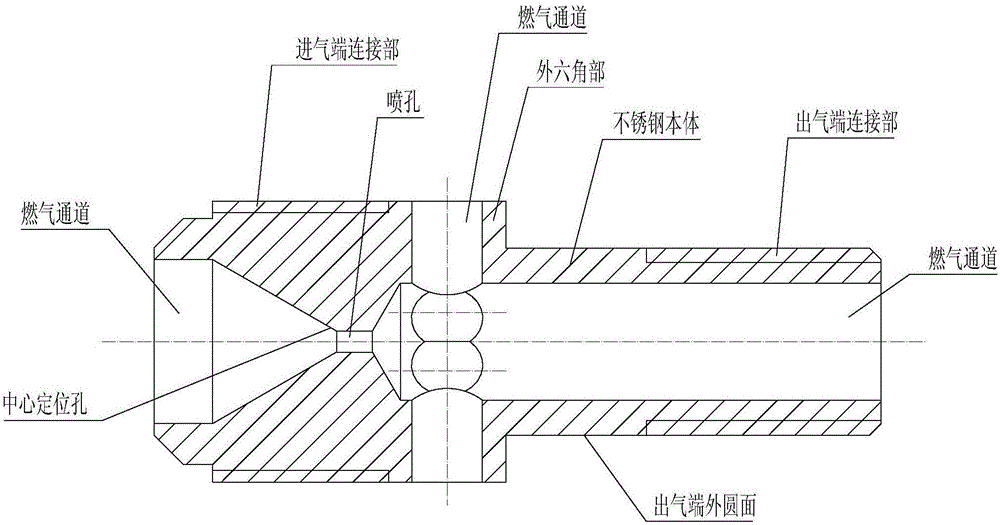

[0050] Such as figure 1 and Figure 4 shown to manufacture figure 1 Taking the stainless steel nozzle of the gas stove as an example, the manufacturing method of the stainless steel nozzle of the gas stove of the present invention comprises the following steps:

[0051] The stainless steel nozzle body with gas channel is processed with stainless steel material, specifically: the stainless steel material is fed into the multi-station cold heading machine, and the multi-station cold heading machine extrudes the stainless steel nozzle body with gas channel, stainless steel The nozzle body also has the outer circular surface of the gas outlet and the outer hexagon part formed together with the stainless steel nozzle body, and the stainless steel nozzle body reserves a position for drilling the nozzle hole at the axis of the gas channel to reduce extrusion. Difficult to design the die, to ensure the low roughness of the gas channel, the stainless steel material can be extruded by...

Embodiment 3

[0058] Such as figure 1 and Figure 4 shown to manufacture figure 1 Taking the stainless steel nozzle of the gas stove as an example, the manufacturing method of the stainless steel nozzle of the gas stove of the present invention comprises the following steps:

[0059] The stainless steel nozzle body with gas channel is processed with stainless steel material, specifically: the stainless steel material is fed into the multi-station cold heading machine, and the multi-station cold heading machine extrudes the stainless steel nozzle body without gas channel, The stainless steel nozzle body has the outer circular surface of the gas outlet and the outer hexagonal part formed together with the stainless steel nozzle body. The number of stations of the multi-station cold heading machine can be 2 to 4 stations, which can be determined according to the production of gas stove stainless steel. The size and style of the nozzle are determined; the gas channel is turned on the stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com