Combined box girder and manufacturing method thereof

A manufacturing method and combined box technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of heavy workload of box girders, and achieve the effects of small on-site workload, reduced environmental impact, and reduced difficulty in quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

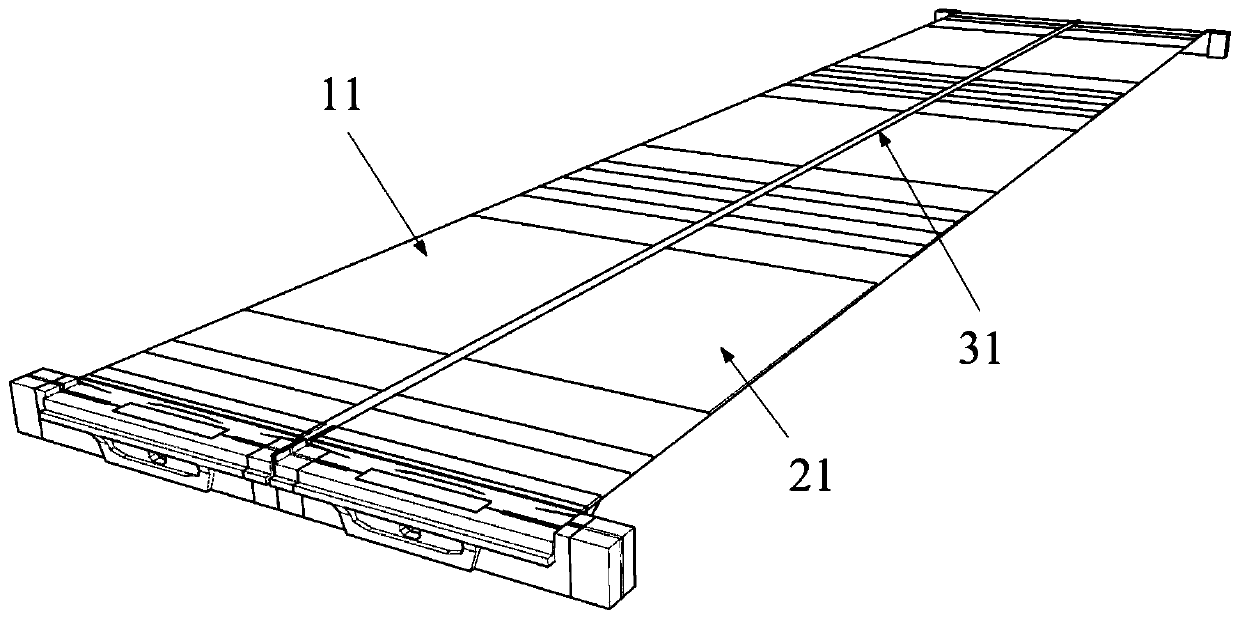

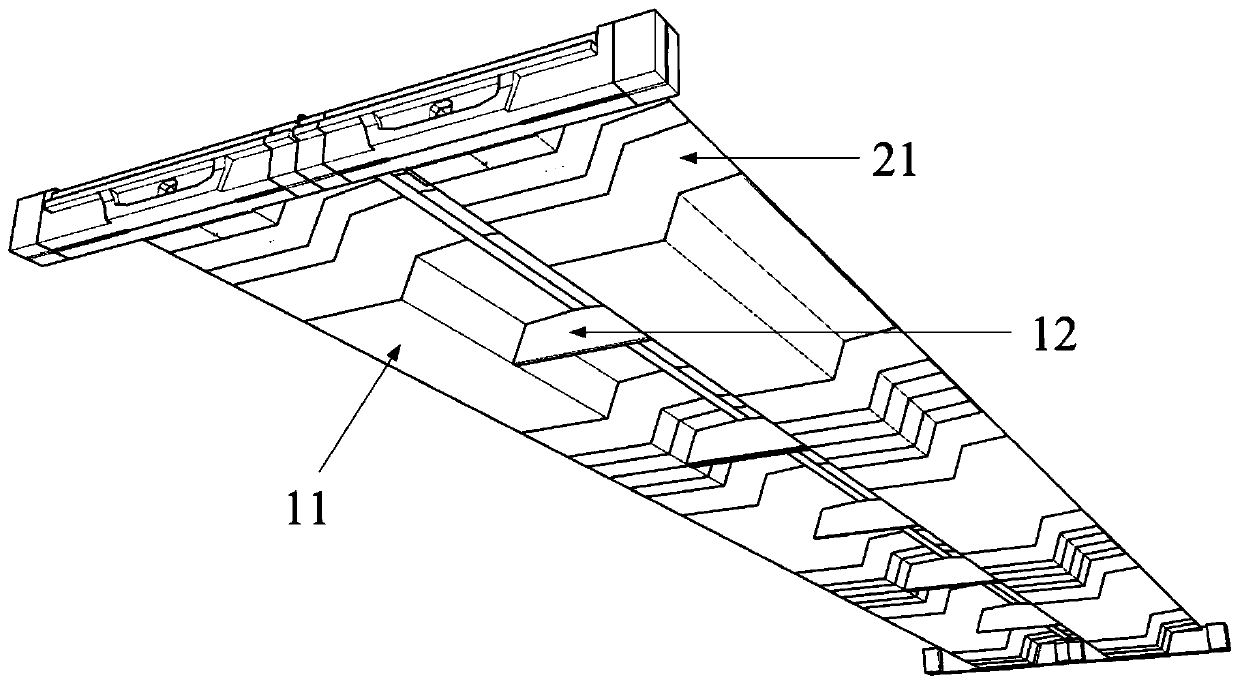

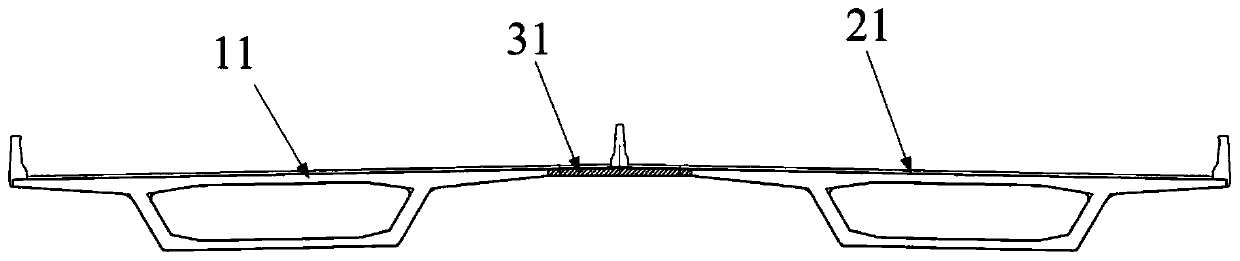

[0052] Such as Figure 1-Figure 13 As shown, the combined box girder provided by the embodiment of the present invention includes: a first beam section 11 and a second beam section 21, and there is a first gap between the first beam section 11 and the second beam section 21, and the first gap is set There are a first connecting piece 13 and a second connecting piece 23, the first connecting piece 13 is connected to the flange plate 34 of the first beam section 11, the second connecting piece 23 is connected to the flange plate 34 of the second beam section 21, and the second connecting piece 13 is connected to the flange plate 34 of the second beam section 21. The first connecting piece 13 and the second connecting piece 23 are fixed by the first binding piece 33 , and the first gap is poured with concrete so that the first joint 31 is formed between the first beam section 11 and the second beam section 21 .

[0053] Specifically, the first beam section 11 and the second beam ...

no. 2 example

[0072] This embodiment provides a method for manufacturing a composite box girder, which is used to manufacture the composite box girder provided in the first embodiment above, including:

[0073] manufacturing the first beam section and the second beam section with the first connector secured to the flange plate of the first beam segment and the second connector secured to the flange plate of the second beam segment;

[0074] Assembling the first beam section and the second beam section, adjusting the width of the first gap between the first beam section and the second beam section;

[0075] connecting the bottom formwork with the first beam section and the second beam section respectively, and the bottom side formwork is located below the first gap;

[0076] binding the first connecting piece and the second connecting piece together through the first binding piece;

[0077] Concrete is poured at the first gap to connect the first beam section to the second beam section.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com