SCR (Selective Catalytic Reduction) denitration catalyst as well as preparation method and application of SCR denitration catalyst

A technology of denitrification catalyst and titanium dioxide, which is applied in the field of preparation of SCR denitrification catalyst, can solve problems such as the difficulty of applying industrial combustion equipment to flue gas denitrification, and achieve high activity and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

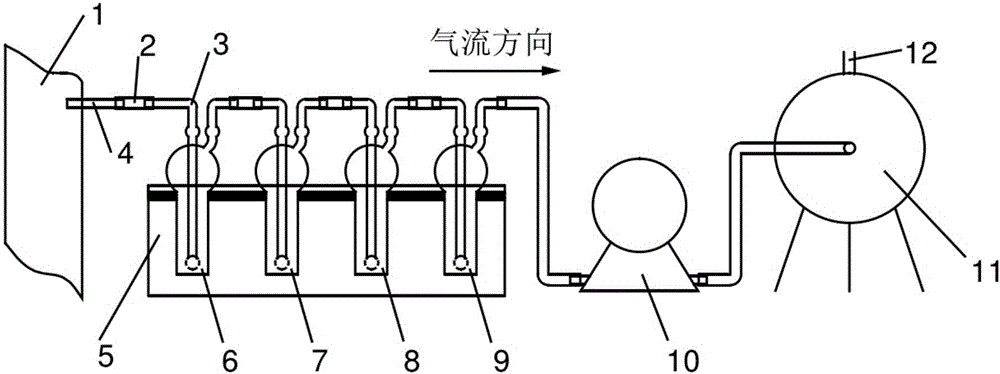

Image

Examples

Embodiment 1

[0028] This example is used to illustrate the SCR denitration catalyst provided by the present invention and its preparation method.

[0029] (1) Add ammonium metavanadate, ammonium paratungstate, and ammonium heptamolybdate into 128g of 5% monoethanolamine aqueous solution at a mass ratio of 1:3:3, and stir until completely dissolved at room temperature to obtain solution A;

[0030] (2) Add 90g of titanium dioxide powder into solution A, dip and stir for 2 hours to obtain suspension B;

[0031] (3) Add 2.5g of cerium nitrate hexahydrate to the suspension B, immerse and stir for 1h, then add 0.16g of ammonium sulfate, immerse and stir for 1h to obtain the suspension C;

[0032] (4) Heat the suspension C to 100°C, continue to stir until it becomes a paste, then dry it at 120°C for 5 hours, and grind the dried material into a 250-mesh powder;

[0033] (5) Calcining the powder obtained in step (4) at 500° C. for 5.5 hours to obtain the SCR denitration catalyst of the present in...

Embodiment 2

[0035] This example is used to illustrate the SCR denitration catalyst provided by the present invention and its preparation method.

[0036] (1) Add ammonium metavanadate, ammonium paratungstate, and ammonium heptamolybdate into 128g of 5% monoethanolamine aqueous solution at a mass ratio of 1:4:4, and stir until completely dissolved at room temperature to obtain solution A;

[0037] (2) Add 85g of titanium dioxide powder into solution A, dip and stir for 2 hours to obtain suspension B;

[0038] (3) Add 8 g of cerium nitrate hexahydrate to the suspension B, immerse and stir for 1 h, then add 1 g of antimony acetate, immerse and stir for 1.5 h, then add 1 g of ammonium sulfate, immerse and stir for 1 h to obtain suspension C;

[0039] (4) Heat the suspension C to 100°C, continue to stir until it becomes a paste, then dry it at 120°C for 5 hours, and grind the dried material into a 300-mesh powder;

[0040] (5) Calcining the powder obtained in step (4) at 500° C. for 3 hours t...

Embodiment 3

[0042] This example is used to illustrate the SCR denitration catalyst provided by the present invention and its preparation method.

[0043] (1) Add ammonium metavanadate, ammonium paratungstate, and ammonium heptamolybdate into 128g of 5% monoethanolamine aqueous solution at a mass ratio of 1:5:5, and stir until completely dissolved at room temperature to obtain solution A;

[0044] (2) Add 75g of titanium dioxide powder into solution A, dip and stir for 2 hours to obtain suspension B;

[0045] (3) Add 12g of cerium nitrate hexahydrate to the suspension B, immerse and stir for 1h, then add 1.5g of antimony acetate, immerse and stir for 1.5h, then add 4g of ammonium sulfate, immerse and stir for 1h to obtain suspension C;

[0046] (4) Heat the suspension C to 100°C, continue to stir until it becomes a paste, then dry it at 120°C for 5 hours, and grind the dried material into a 500-mesh powder;

[0047] (5) Calcining the powder obtained in step (4) at 500° C. for 5 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com