Fish collagen repair sponge and preparation method thereof

A technology of fish collagen and fish skin collagen, which is applied in the field of collagen sponge and its preparation, can solve the problems of uncontrollable cytotoxicity, poor biocompatibility, and low bioactivity, and achieve biocompatibility and high porosity , Uniform and moderate pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of collagen raw material:

[0031] Take fish skin, clean and dehydrate, add 400ml 10% n-butanol to degrease, stir at 0-4°C for 8 hours, add 0.05M NaOH solution and stir for 10 hours, then fully wash with deionized water and treat with alkali solution fish skin until neutral.

[0032] Put the washed fish skin into a 0.5M acidic solution at a material-to-liquid ratio of 1:5 (w / w), add protease and stir for 24 hours, enzymatically treat it to obtain enzymatic collagen solution, and finally add 200ml of absolute ethanol Solution, finally the ethanol content in the collagen solution reaches 70%, stand still, filter to obtain collagen, then dehydrate with absolute ethanol, dry in low temperature vacuum to obtain collagen powder, and obtain medical grade biomaterials with molecular weight up to 300kD. Polymer fish skin collagen.

[0033] Preparation of collagen repair sponge:

[0034] Take the above-mentioned freeze-dried fish skin collagen raw material, dissolv...

Embodiment 2

[0039] Preparation of collagen raw material:

[0040] Take the fish skin, clean it and dehydrate it, add 600ml of 10% n-butanol to degrease, stir at 0-4°C for 12 hours, then add 0.2M NaOH solution and stir for 8 hours, then fully wash it with deionized water and treat it with alkali solution fish skin until neutral.

[0041] Put the washed fish skin into a 0.5M acidic solution at a material-to-liquid ratio of 1:10 (w / w), add protease and stir for 24 hours, enzymatically treat it to obtain an enzymatic collagen solution, and finally add 100ml of absolute ethanol Solution, finally the ethanol content in the collagen solution reaches 50%, stand still, filter to obtain collagen, then dehydrate with absolute ethanol, dry in low temperature and vacuum to obtain collagen powder, and obtain medical grade biomaterials with a molecular weight of up to 300kD. Polymer fish skin collagen.

[0042] Preparation of collagen repair sponge:

[0043] Take the above-mentioned freeze-dried fish...

Embodiment 3

[0047] The preparation method of the fish collagen raw material is the same as in Example 2.

[0048] Preparation of collagen sponge:

[0049] Take the above-mentioned freeze-dried fish skin collagen raw material, dissolve it completely with glacial acetic acid, the solution solubility is 15 mg / ml, measure its pH to be 5, let it stand at 25°C for 24 hours, and carry out self-assembly of micro-nano structure.

[0050] The above self-assembled collagen solution was poured into a mold, and vacuum freeze-dried at -80° C. for 36 hours to obtain a fish collagen sponge.

[0051] Immerse the freeze-dried fish collagen sponge in 1% genipin solution for cross-linking for 48 hours, then wash it with 1% glycine, finally wash it with purified water, freeze-dry it again, and then pack it and sterilize it by irradiation After processing, the fish skin collagen repair sponge is obtained.

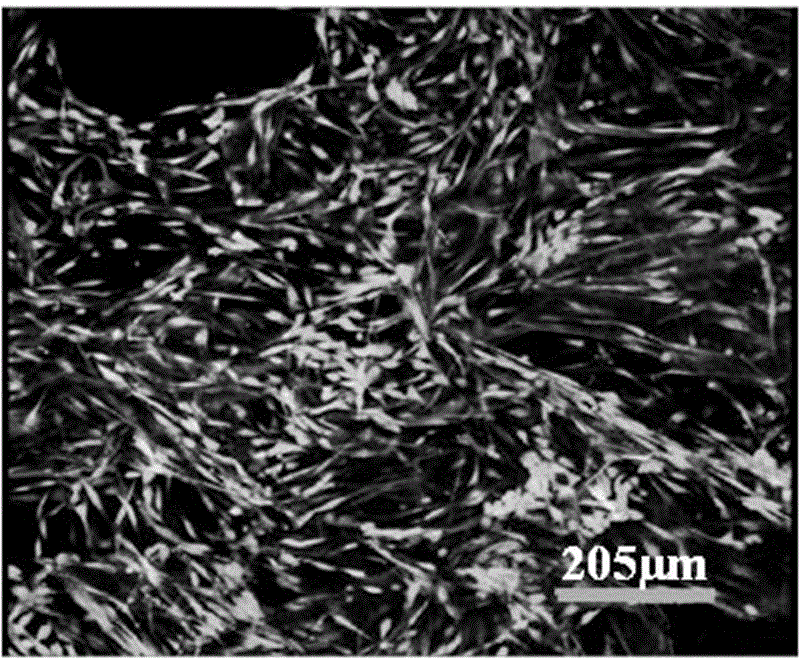

[0052] Sterilize the above-mentioned collagen sponge for in vitro cell experiments, the operation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com