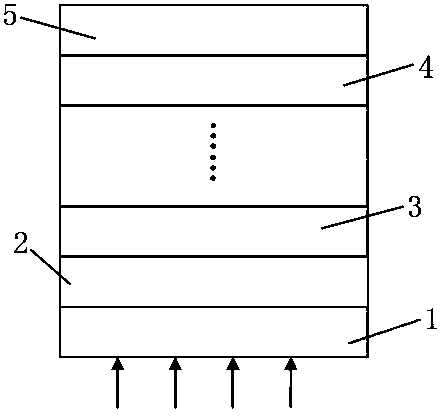

A kind of preparation method of nanocrystalline silicon thin film solar cell

A technology of solar cells and nanocrystalline silicon, applied in the field of solar cells, can solve problems such as ineffective conversion of electric energy, and achieve the effects of improving photoelectric conversion efficiency, improving stability and reducing light absorption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

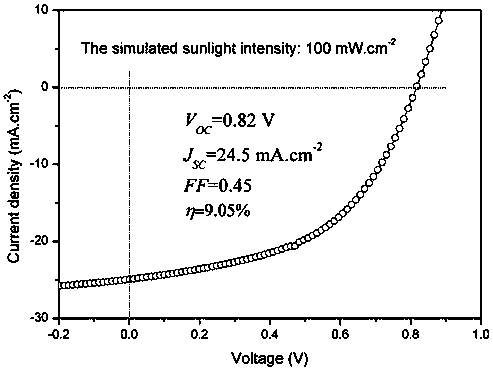

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] 1.1 Main raw materials

[0018] ITO conductive glass: area ~4.0×4.0 cm 2 , sheet resistance ~15 Ω, light transmittance ³90%, Luoyang Longgan Glass Co., Ltd.;

[0019] Silane, phosphine, borane, carbon dioxide, hydrogen and other growth gas sources: purity greater than 99.995%, Dalian Date Gas Co., Ltd.;

[0020] 1.2 Main production equipment

[0021] Plasma Chemical Vapor Deposition (PECVD) system: the vacuum chamber is composed of 4 independent vacuum chambers in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com