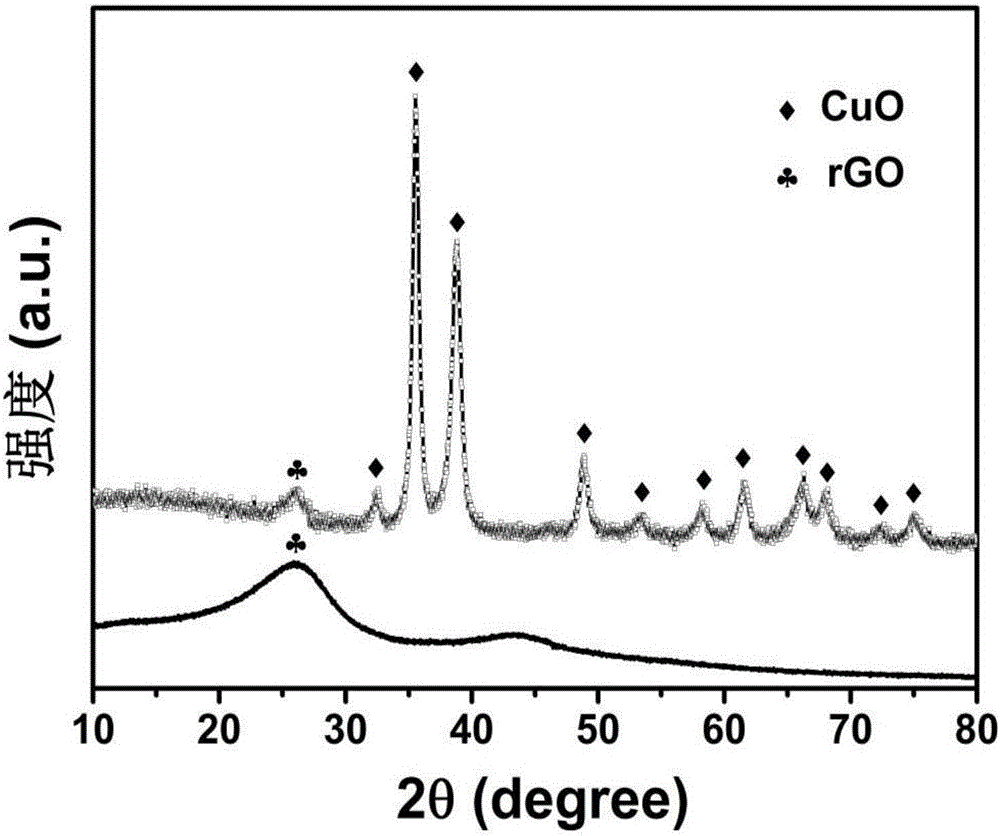

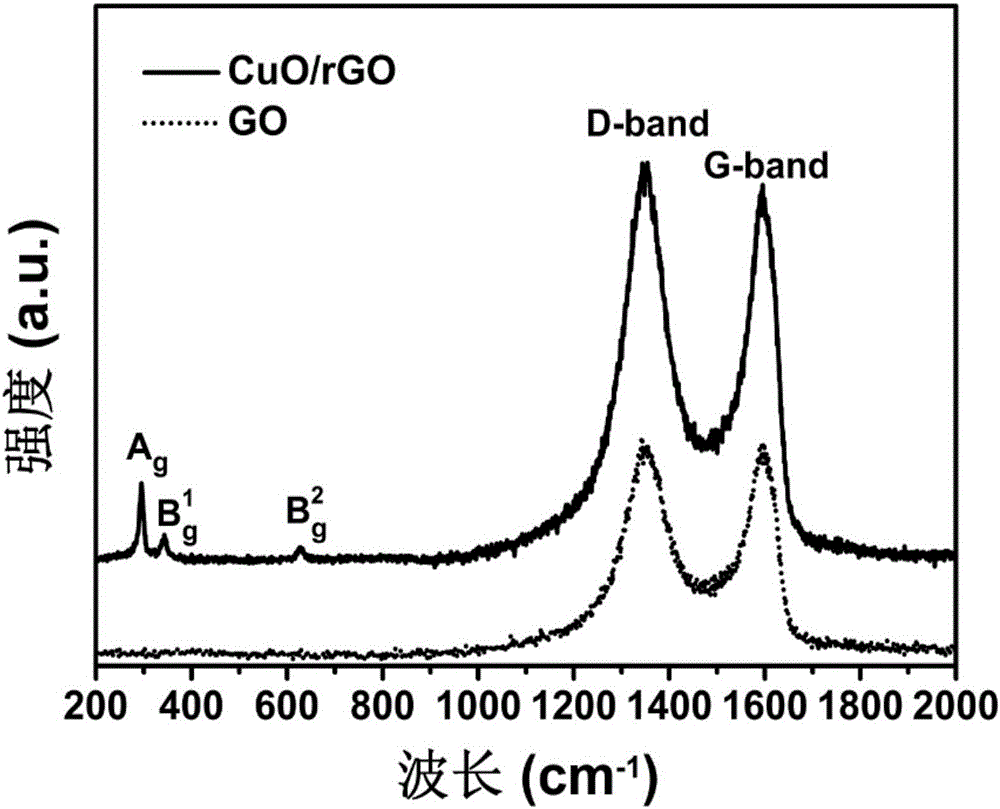

In-situ preparation method for cubic copper oxide/graphene aerogel composite material

A technology of graphene airgel and composite materials, which is applied in the field of in-situ preparation of cubic copper oxide/graphene airgel composite materials, can solve the problem of low electrochemical energy storage performance and photocatalytic activity, and the recovery of powder catalysts. Difficult to use, cumbersome and complex synthesis methods, etc., to achieve excellent photocatalytic and electrochemical energy storage performance, conducive to infiltration and migration, and fast and effective transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment discloses an in-situ preparation method of cubic copper oxide / graphene aerogel composite material, including the following steps:

[0029] S1: Put the copper mesh into 1M hydrochloric acid, absolute ethanol and deionized water for ultrasonic cleaning, and then dry it;

[0030] S2: Disperse 100mg of graphene oxide in 100ml of deionized water and sonicate for 1 hour to obtain a concentration of 1mg mL -1 Graphene oxide dispersion liquid;

[0031] S3: Pour the graphene oxide dispersion obtained in step S2 into the inner liner of the autoclave, and then put the copper mesh obtained in step S1 into the inner liner of the autoclave to perform a hydrothermal reaction, the hydrothermal reaction temperature is 160°C, and the reaction time Is 10h;

[0032] S4: The product obtained in step S3 is taken out, quenched and freeze-dried to obtain a copper oxide / graphene aerogel composite material; the freeze-drying time is 12h, the freeze-drying temperature is -30°C, and the va...

Embodiment 2

[0034] This embodiment discloses an in-situ preparation method of cubic copper oxide / graphene aerogel composite material, including the following steps:

[0035] S1: Put the copper mesh into 3M hydrochloric acid, absolute ethanol and deionized water for ultrasonic cleaning, and then dry it;

[0036] S2: Disperse 200mg of graphene oxide in 100ml of deionized water, and sonicate for 2 hours to obtain a concentration of 2mg mL -1 Graphene oxide dispersion liquid;

[0037] S3: Pour the graphene oxide dispersion obtained in step S2 into the inner liner of the autoclave, and then put the copper mesh obtained in step S1 into the inner liner of the autoclave to perform a hydrothermal reaction, the hydrothermal reaction temperature is 180°C, and the reaction time Is 12h;

[0038] S4: The product obtained in step S3 is taken out, quenched and freeze-dried to obtain a copper oxide / graphene aerogel composite material; the freeze-drying time is 15h, the freeze-drying temperature is -50°C, and the ...

Embodiment 3

[0043] This embodiment discloses an in-situ preparation method of cubic copper oxide / graphene aerogel composite material, including the following steps:

[0044] S1: Put the copper mesh into 3M hydrochloric acid, absolute ethanol and deionized water for ultrasonic cleaning, and then dry it;

[0045] S2: Disperse 300mg of graphene oxide in 100ml of deionized water and sonicate for 3 hours to obtain a concentration of 3mg mL -1 Graphene oxide dispersion liquid;

[0046] S3: Pour the graphene oxide dispersion obtained in step S2 into the inner liner of the autoclave, and then put the copper mesh obtained in step S1 into the inner liner of the autoclave to perform a hydrothermal reaction. The hydrothermal reaction temperature is 200°C, and the reaction time 15h;

[0047] S4: The product obtained in step S3 is taken out, quenched and freeze-dried to obtain a copper oxide / graphene aerogel composite material; the freeze-drying time is 24h, the freeze-drying temperature is -40°C, and the vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com