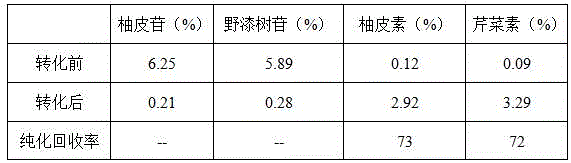

Method for preparing naringenin and apigenin by converting exocarpium citrus grandis leaf flavone by using microorganism

A technology of microbial transformation and naringenin, applied in the direction of fermentation, can solve the problems of complex process and large amount of iodine, and achieve the effects of mild conditions, high conversion rate and avoiding pollution problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Pick the young leaves of tangerine red, wash them, and dry them in the sun or in an oven at 60°C to constant weight, and crush them through an 80-mesh sieve for later use. Take 100 g of leaf powder, moisten it with distilled water, stir it well, put it in a petri dish with a diameter of 12 cm, open it, and put it in an incubator with a temperature of 25 ° C and a humidity of 85% for 72 hours. Bacteria or molds that grow naturally strains. Grind 150g of boiled potatoes into a slurry, add 50g of citrus fruit powder, shake well, and dilute to 1000mL with water to make potato seed fungus culture medium. Inoculate 2 g of the above strains (including culture medium) into 500 mL of potato liquid seed fungus culture medium, and incubate at 30°C and 180 rpm for 60 h to obtain a seed fungus culture solution.

[0029] Take 1000g of citrus red leaf powder and add 3000mL of water, stir well to form a transformation medium, add 250mL of the above-mentioned cultured seed bacteria sol...

Embodiment 2

[0034]Pick the young leaves of tangerine red, wash them, and dry them in the sun or in an oven at 60°C to constant weight, and crush them through an 80-mesh sieve for later use. Take 100 g of leaf powder, add 200 mL of distilled water, moisten it, stir well, divide it into petri dishes with a diameter of 12 cm, open it, and culture it in an incubator with a temperature of 25 °C and a humidity of 95% for 96 hours to obtain seed fungi. Grind 150g of boiled potatoes into a slurry, add 50g of citrus fruit powder, shake well, and dilute to 1000mL with water to make potato seed fungus culture medium. Inoculate 3 g of the above strains (including culture medium) into 500 mL of potato liquid seed fungus culture medium, and incubate at 35°C and 220 rpm for 48 h to obtain a seed fungus culture solution.

[0035] Take 1000g of citrus red leaf powder and add 3500mL of water, stir well to form a transformation medium, add 200mL of the above-mentioned cultured seed bacteria solution, stir e...

Embodiment 3

[0040] Pick the young leaves of tangerine red, wash them, and dry them in the sun or in an oven at 60°C to constant weight, and crush them through an 80-mesh sieve for later use. Take 100 g of leaf powder and add 200 mL, moisten it, stir well, divide it into petri dishes with a diameter of 12 cm, open it, and culture it in an incubator with a temperature of 35 °C and a humidity of 95% for 84 hours to obtain seed fungi. Grind 150g of boiled potatoes into a slurry, add 50g of citrus fruit powder, shake well, and dilute to 1000mL with water to make potato seed fungus culture medium. Inoculate 3 g of the above strains (including culture medium) into 500 mL of potato liquid seed fungus culture medium, and incubate at 40°C and 250 rpm for 72 h to obtain a seed fungus culture solution.

[0041] Take 1000g of citrus red leaf powder and add 4000mL of water, stir well to form a transformation medium, add 250mL of the above-mentioned cultured seed bacteria solution, stir evenly, divide i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com