Preparation method for tissue-derived carbon fiber loaded MoS2 microflower composite material and application in lithium-sulfur battery

A composite material and lithium-sulfur battery technology, applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve problems such as poor electrochemical performance, and achieve high conductivity, easy implementation, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

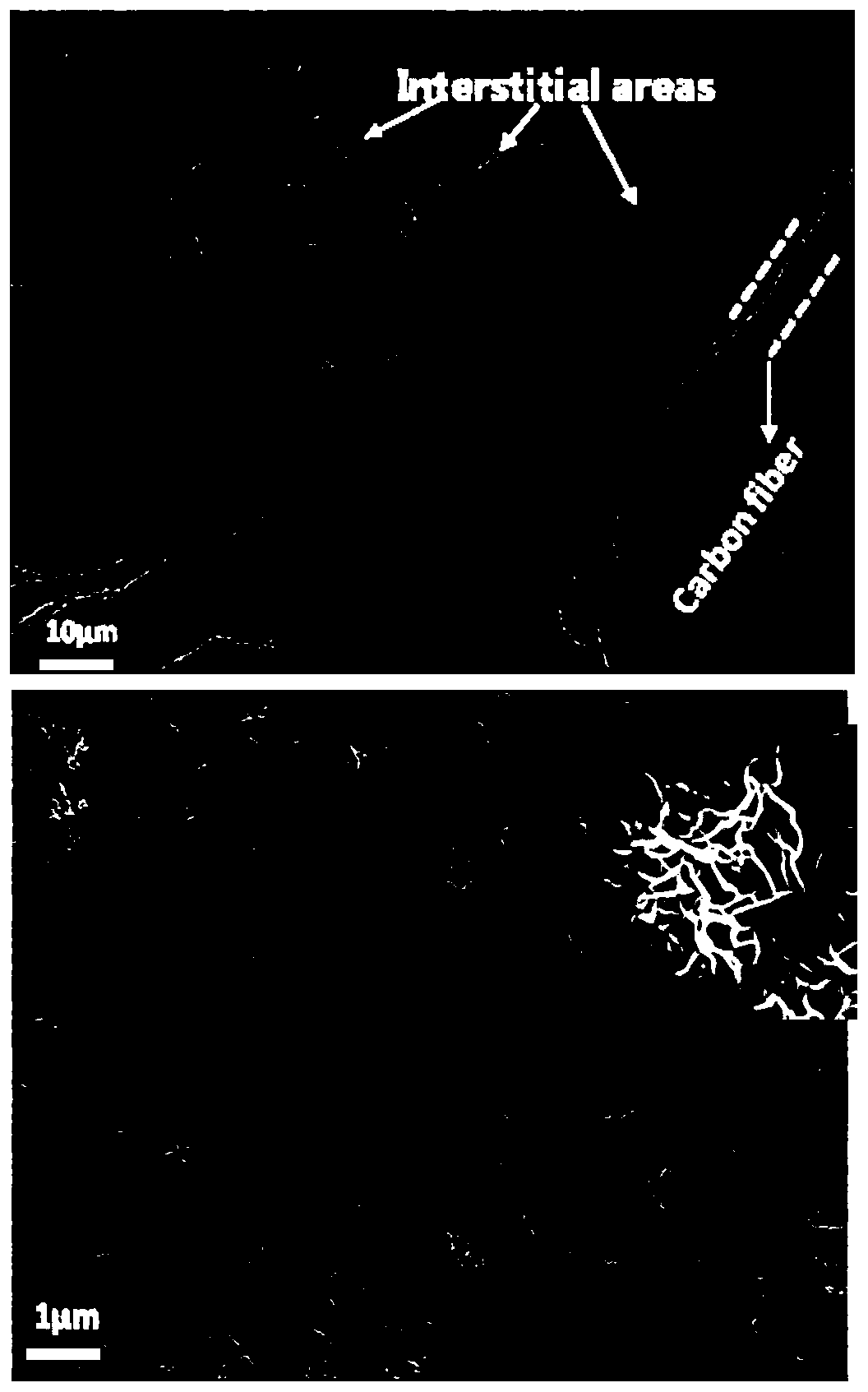

[0040] MoS 2 Preparation of / C: Soak commercial paper towels (Qingfeng) in 20 mL of 1 mol / L HCl for 24 h, then wash with water until neutral, 80 o C dried overnight, dissolved 76.7 mg of ammonium molybdate tetrahydrate and 1 g of thiourea in 20 mL of water, then soaked 76.7 mg of treated paper towels in the above solution, 180 o C hydrothermal treatment for 24 h, then suction filtered, washed to neutral, at 80 o Dry overnight at C, put the obtained sample into a vacuum tube furnace, and place it in an Ar atmosphere at 800 o C calcined for 2 h.

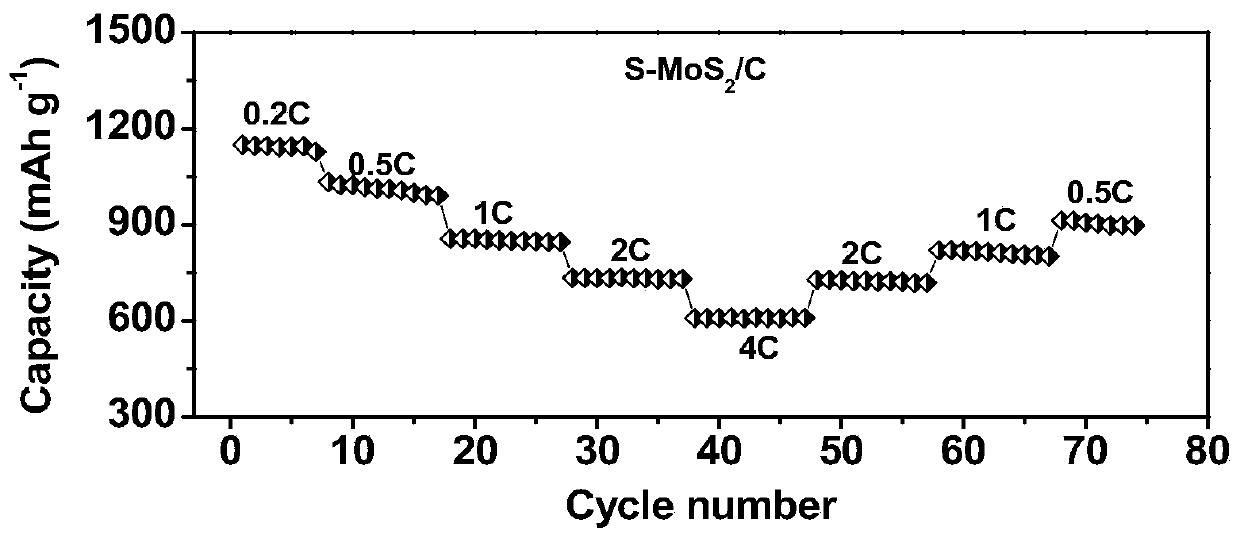

[0041] S-MoS 2 Preparation of / C: Sulfur powder and MoS 2 / C mixed, thoroughly ground, then sealed in vials, and finally put the vials containing the mixture into a vacuum tube furnace under Ar atmosphere at 300 oC heated for 4 hours and cooled to room temperature to obtain S-MoS 2 / C.

[0042] Preparation of slurry: weigh 80 mg S-MoS 2 / C, 10 mg Super . P, 10 mg PVDF, and 200 µL NMP were ball milled for 3 hours and mixed unifo...

Embodiment 2

[0051] MoS 2 / Preparation of C-12: Soak commercial paper towels in 20 mL of 1 mol / L HCl for 24 h, then wash with water until neutral, 80 o C dried overnight, dissolved 76 mg of ammonium molybdate tetrahydrate and 1 g of thiourea in 20 mL of water, then soaked 76 mg of treated paper towels in the above solution, 180 o C hydrothermal treatment for 12 h, then suction filtered, washed with water until neutral, at 80 o Dry overnight at C, put the obtained sample into a vacuum tube furnace, and place it in an Ar atmosphere at 800 o C calcined for 2 h.

[0052] S-MoS 2 Preparation of / C-12: Sulfur powder and MoS 2 / C-12 mixed, fully ground, then sealed in vials, and finally put the vials containing the mixture into a vacuum tube furnace under Ar atmosphere at 300 o C heated for 4 hours and cooled to room temperature to obtain S-MoS 2 / C-12.

[0053] Preparation of slurry: weigh 80 mg S-MoS 2 / C-12, 10 mg Super . P and 10 mg PVDF, 200 µL NMP ball milled for 3 hours and mixed e...

Embodiment 3

[0059] MoS 2 Preparation of / C: Soak commercial paper towels in 20 mL of 1 mol / L HCl for 24 h, then wash with water until neutral, 80 o C dried overnight, dissolved 76 mg of ammonium molybdate tetrahydrate and 1 g of thiourea in 20 mL of water, then soaked 140 mg of treated paper towels in the above solution, 180 o C hydrothermal treatment for 24 h, then suction filtered, washed to neutral, at 80 o Dry overnight at C, put the obtained sample into a vacuum tube furnace, and place it in an Ar atmosphere at 800 o C calcined for 2 h.

[0060] S-MoS 2 Preparation of / C: Sulfur powder and MoS 2 / C mixed, thoroughly ground, then sealed in a vial, and finally put the vial containing the mixture into a vacuum tube furnace under an Ar atmosphere at 300 o C heated for 4 hours and cooled to room temperature to obtain S-MoS 2 / C.

[0061] Preparation of slurry: weigh 80 mg S-MoS 2 / C, 10 mg Super . P, 10 mg PVDF, and 200 µL NMP were ball milled for 3 hours and mixed uniformly to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com