Active coke preparation device and method

A preparation device and activated coke technology, which is applied in the field of coal chemical industry, can solve the problems of high cost, tar clogging, poor continuous operation ability, etc., and achieve the effect of alleviating easy clogging, low operation cost, and continuous and stable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

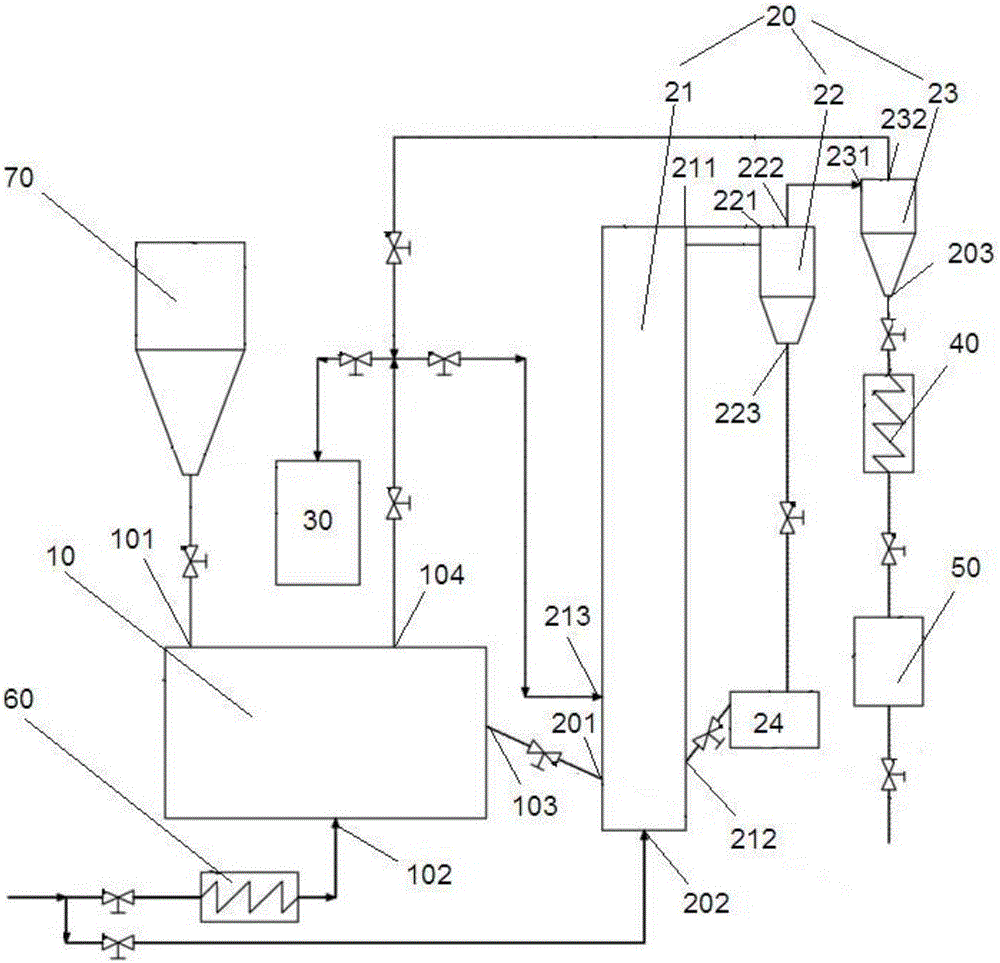

[0048] Such as figure 1 As shown, the device for preparing active coke by the two-step method of the present invention, taking boiler combustion flue gas as fluidization gas and bituminous coal for preparing active coke as an example, introduces the working principle of the device as follows:

[0049] Operating parameters: the flue gas temperature is 1000°C; the operating temperature of the low-temperature pyrolysis furnace 10 is 500°C; the operating temperature of the circulating fluidized bed body 21 is 850°C; The processing device 30 is a boiler, and the pyrolysis gas is used for combustion to generate heat; the separation particle size of the first gas-solid separation device 22 is greater than 150 μm; the second gas-solid separation device 23 can separate active coke with a particle size of less than 100 μm.

[0050] Gas flow: the flue gas at 1000°C enters the heat exchanger 60, and enters the low-temperature pyrolysis furnace 10 in the form of fluidized air after cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com