Resin matrix applicable to microwave curing and preparation method of resin matrix

A microwave curing and resin matrix technology, applied in the field of composite material preparation, can solve the problems of high viscosity, low resin molecular polarity and high resin matrix viscosity, and achieve excellent comprehensive mechanical properties, high dimensional stability and good heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

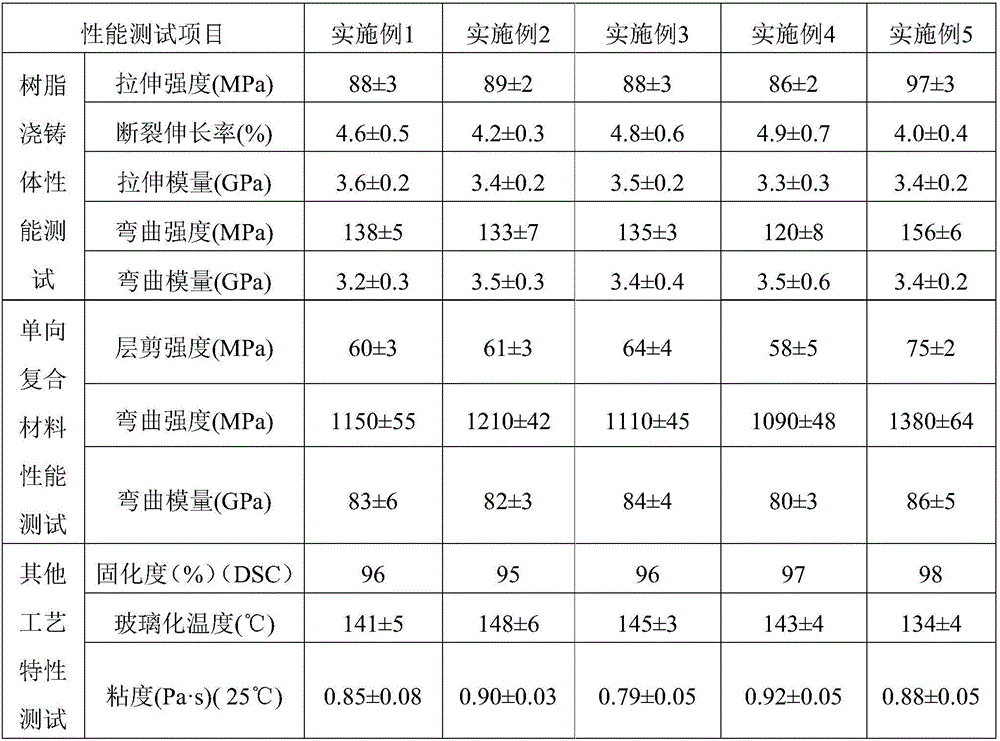

Examples

Embodiment 1

[0022] The main resin is fluorine-containing glycidyl ether (DGEBHFA), the diluent is phenyl glycidyl ether type epoxy resin (H63), and the curing agent is a compound of low-viscosity polyamide V-125 and boron trifluoride-benzylamine Anchor1040 The nano-filler adopts carbon nanofiber, and the carbon fiber adopts T700 from Japan Toray Company. The mass ratio of main resin, diluent, curing agent and nano filler is 60:40:50::0.5. The preparation process is as follows: according to the formula, first mix the low-viscosity polyamide V-125 and boron trifluoride-benzylamine Anchor1040 at room temperature to obtain a curing agent compound, and mix the main resin, nano filler Mixed with diluent and ultrasonically treated, ultrasonic treatment conditions: power 60Kw, temperature 30°C, time 2h. Then mix the main resin, nano filler, diluent and curing agent evenly, the mixing conditions are oil bath temperature 60°C, stirring speed 800 rpm, time 40min. Then the mixed resin matrix was pl...

Embodiment 2

[0027]The main resin adopts fluorine-containing glycidyl ether (DGEBHFA) and fluorine-containing glycidyl ester (BGTF), the diluent adopts benzyl glycidyl ether type epoxy resin (692), and the curing agent adopts aminocyclotripolyphosphazene HANPCP and low-viscosity The compound of polyamide V-125, the nano filler is montmorillonite, and the carbon fiber is T700 from Toray Corporation of Japan. The mass ratio of main resin, diluent, curing agent and nano filler is 70:30:45:1. The preparation process is as follows: according to the formula, first mix aminocyclotripolyphosphazene HANPCP and low-viscosity polyamide V-125 at 60°C to obtain a curing agent compound, and mix the main resin, nano filler Mixed with diluent and ultrasonically treated, ultrasonic treatment conditions: power 60Kw, temperature 30°C, time 2h. Then mix the main resin, nano filler, diluent and curing agent evenly, the mixing conditions are oil bath temperature 60°C, stirring speed 800 rpm, time 40min. Then ...

Embodiment 3

[0032] The main resin adopts sulfur-containing glycidyl ether (DGEBS) and fluorine-containing glycidyl ester (BGTF), the diluent adopts glycidyl neodecanoate type epoxy resin (H11), and the curing agent adopts aminocyclotripolyphosphazene HANPCP and three The complex of boron fluoride-benzylamine Anchor1040, the nano-filler uses carbon nanotubes, and the carbon fiber uses T700 from Toray Corporation of Japan. The mass ratio of main resin, diluent, curing agent and nano filler is 80:20:45:2. The preparation process is as follows: according to the formula, first mix aminocyclotripolyphosphazene HANPCP and boron trifluoride-benzylamine Anchor1040 at 60°C to obtain a curing agent compound, and mix the main resin, nano Filler and diluent are mixed and ultrasonically treated, ultrasonic treatment conditions: power 60Kw, temperature 30°C, time 2h. Then mix the main resin, nano filler, diluent and curing agent evenly, the mixing conditions are oil bath temperature 60°C, stirring spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com