Preparation method of fiber-reinforced Al2O3-SiO2 aerogel material with wave transmission and heat insulation integrated function

A fiber-reinforced, aerogel technology, applied in the field of aerogel material preparation, can solve problems such as low thermal conductivity, and achieve the effects of low thermal conductivity, high wave transmittance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

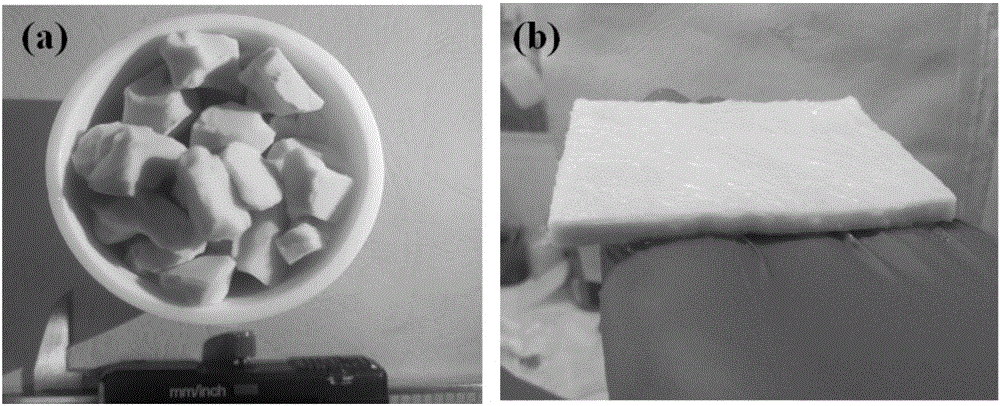

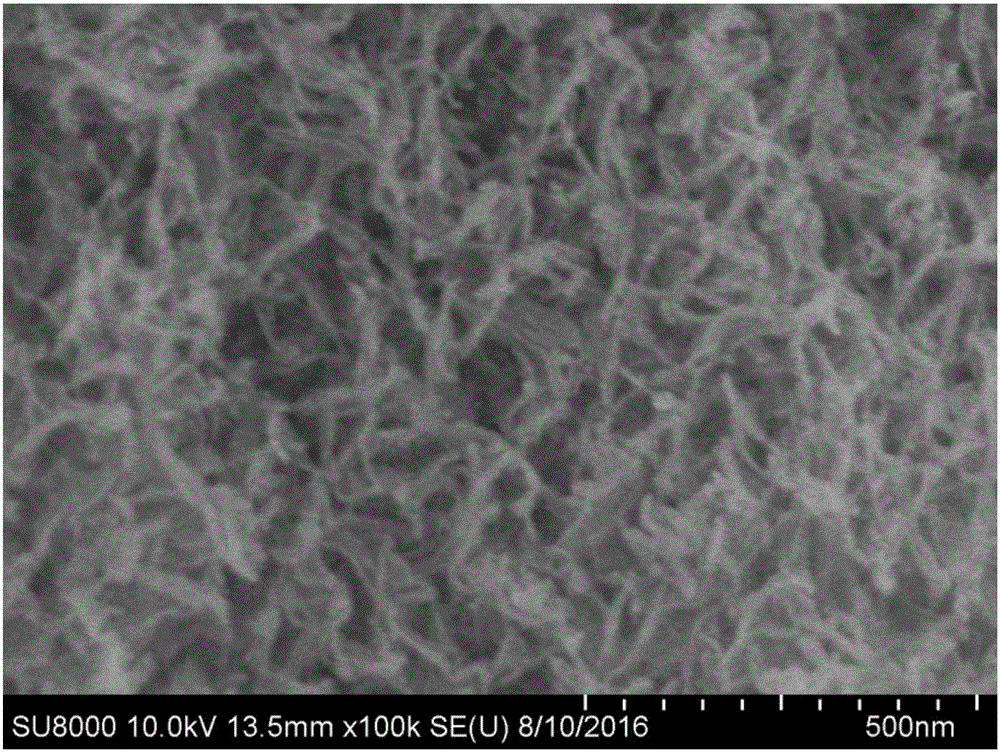

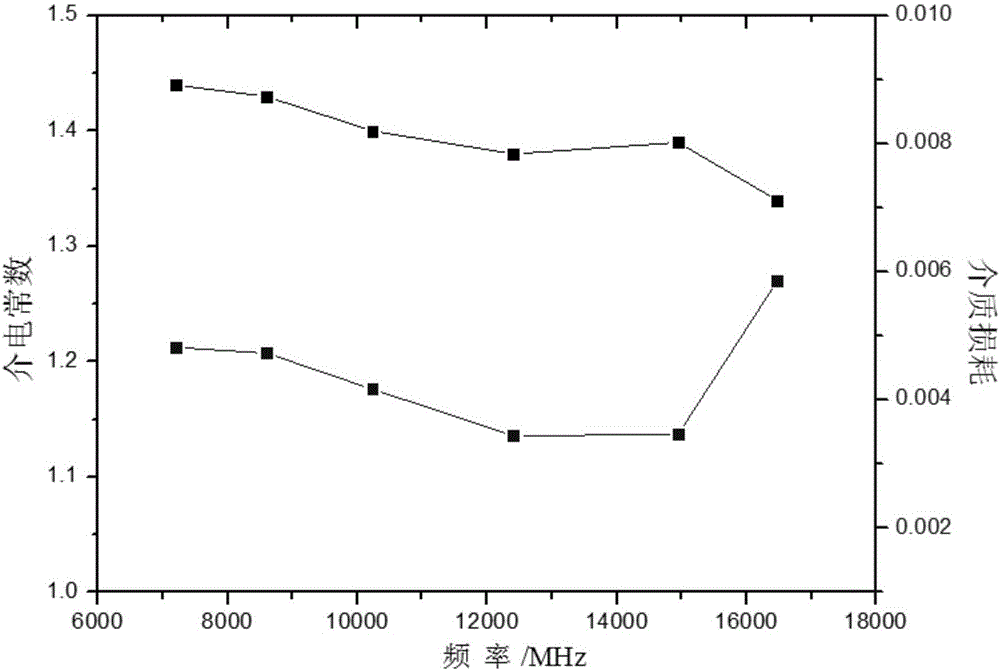

example 1

[0028] After uniformly mixing aluminum chloride hexahydrate, ethanol, water, and tetraethylorthosilicate at a molar ratio of 1:5:60:0.128, uniformly stir at a temperature of 50° C. and a stirring rate of 500 rpm for 2 hours. Then add 50% of silicon nitride powder with excellent wave-transmitting properties into the above sol system, and continue to stir uniformly for 2 hours at a temperature of 50° C. and a stirring rate of 500 rpm to obtain a homogeneous mixture with silicon nitride powder. Add propylene oxide at a molar ratio of 8:1 to aluminum chloride hexahydrate, stir at 500rpm for 0.5h, then pour the mixture into a mold with high-purity quartz fibers to react until it gels, and leave it for 30h Add ethanol aging solution, and replace in an oven at 50°C for 3 times, each time for 12h. Then the wet gel was subjected to ethanol supercritical drying treatment, the reaction temperature was 250°C, the pressure in the autoclave was 10MPa, and the drying time was 2h, to obtain f...

example 2

[0030] After uniformly mixing aluminum nitrate nonahydrate, ethanol, water, and methyl orthosilicate in a molar ratio of 1:10:30:0.5, uniformly stir at a temperature of 25° C. for 0.5 h. Then add 30% boron carbide powder with excellent wave-transmitting properties into the above sol system, and continue to uniformly stir for 0.5 h at a temperature of 25° C. to obtain a uniform mixture with boron carbide powder. Add cis-2,3 butylene oxide at a molar ratio of 5:1 to aluminum nitrate nonahydrate, stir for 1 hour, and pour the mixture into a mold with polycrystalline mullite fibers to react until gelling, and place After 20 hours, ethanol aging solution was added, and replaced in an oven at 45°C for 5 times, 18 hours each time. Then the wet gel is subjected to ethanol supercritical drying treatment, the reaction temperature is 270 ° C, the pressure in the autoclave is 14 MPa, and the drying time is 4 h, and the fiber-reinforced AlOOH-SiO is obtained. 2 airgel material. Finally, ...

example 3

[0032] After uniformly mixing aluminum nitrate nonahydrate, ethanol, water, and methyltriethoxysilane at a molar ratio of 1:25:40:0.75, uniformly stir at a temperature of 40° C. at a stirring rate of 550 rpm for 1 h. Then add 80% boron nitride powder with excellent wave-transmitting properties into the above sol system, and continue to uniformly stir for 1 hour at a temperature of 40° C. and a stirring rate of 550 rpm to obtain a uniform mixture with boron nitride powder. Add oxetane at a molar ratio of 6:1 to aluminum nitrate nonahydrate, stir at a stirring rate of 400rpm for 2h, then pour the mixture into a mold with aluminum silicate fibers to react until it gels, and let it stand for 15h After that, ethanol aging solution was added, and the replacement was carried out in an oven at 70°C for 3 times, each time for 12 hours. Then the wet gel was subjected to carbon dioxide supercritical drying treatment, the reaction temperature was 70°C, the pressure in the autoclave was 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com