Retarded crosslinked gel and preparation method thereof

A technology for cross-linking gels and working fluids, used in gel preparation, chemical instruments and methods, colloid chemistry, etc., and can solve problems such as increased pressure and too fast cross-linking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the above-mentioned profile control working fluid is the same as that of the control and flooding working fluid, specifically: including the following steps:

[0031] ⑴ Add polyglutamic acid to water (can be injected water) under stirring (speed 150-200rpm);

[0032] (2) Observe after stirring for 10 minutes, when there is no flocculent insoluble matter, slowly add anionic polyacrylamide, and continue stirring for 40-60 minutes;

[0033] ⑶ Add sodium dichromate after no obvious fish eyes (polyacrylamide is completely dissolved), and finally add sodium sulfite to make the finished product.

[0034] The pressure of profile control working fluid and control and flooding working fluid will not increase during the injection process, and the cross-linked viscosity after injection into the formation can produce profile control (control and flooding) effects. The data comparison is shown in Table 1:

[0035]

[0036]

[0037] Table 1: The detect...

Embodiment 1

[0040] The daily water injection volume of a water injection well in Dagang Oilfield is about 80m 3 , the water injection pressure is 1.0MPa, and the comprehensive water cut of the surrounding oil wells reaches more than 80%. It is judged that there are obviously large water flow channels inside the oil layer, and profile control operations are required.

[0041] The construction site is two 10m 3 The mixing tank is used for chemical preparation, and the plunger pump is connected to the water injection wellhead to inject into the oil layer to produce profile control effect.

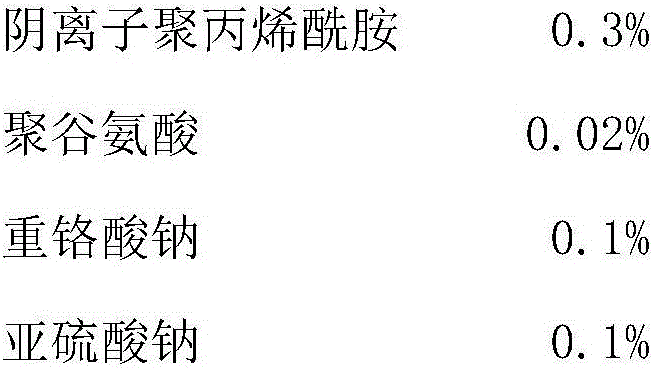

[0042] Working fluid formula: anionic polyacrylamide 0.3%, polyglutamic acid 0.02%, sodium dichromate 0.1%, sodium sulfite 0.1%, local water injection 99.48%.

[0043] Preparation process: a 10m 3 Inject about 8 cubic meters of local water into the mixing tank, start stirring, add polyglutamic acid at 0.02%, stir for about 10 minutes, add polyacrylamide to a final concentration of 0.3%, continue stirrin...

Embodiment 2

[0047] The comprehensive water content of the well group in a block of Huabei Oilfield is close to 90%, and the profile control operation has been performed many times, but the profile control effect is getting worse and worse, the validity period is short and the oil increase effect is not ideal. The analysis reason is that the crude oil viscosity in this area Higher (viscosity 10-20mPa*s at 50°C), resulting in poor effect of water flooding after profile control.

[0048] Therefore, in order to improve the oil displacement effect and increase the viscosity of water injection, the oil displacement test was carried out by using the regulating and flooding working fluid containing polyglutamic acid.

[0049] Well group status: This well group includes 1 water injection well, surrounded by 4 beneficial oil wells, with a daily water injection volume of 120m 3 , water injection pressure 2.5MPa.

[0050] Working fluid formula: anionic polyacrylamide 0.2%, polyglutamic acid 0.04%, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com