Preparation method of ulva fasciata polysaccharide-tween 20 compounded beta-carotene emulsion

A carotene and splinter Ulva technology, which is applied in the directions of polysaccharide/gum-containing food ingredients, pharmaceutical formulations, and emulsion transportation, can solve the problems of unstable emulsification of the system, and solve problems such as difficulty in being absorbed by the human body, increase emulsifying ability and Stability, small effect of steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

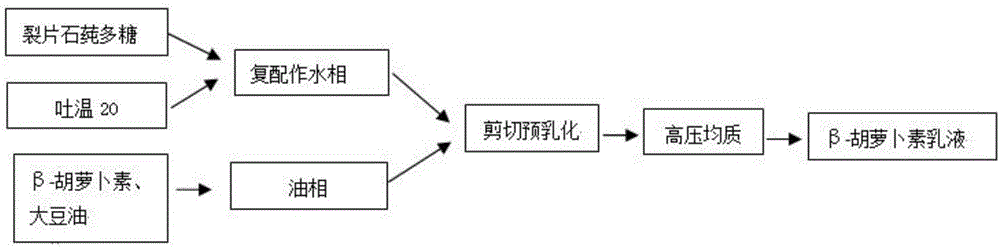

Method used

Image

Examples

Embodiment 1

[0035] (1) Extraction of polysaccharides from Ulva lobes: Wash a certain amount of Ulva lobes, control water, dry in an oven at 60°C, and cut into pieces. Add 95% ethanol solution to immerse and degrease, and let stand overnight. Take out the degreased Ulva sliver and dry it in the sun, add distilled water according to the ratio of solid to liquid 1:10, bathe in 95℃ water for 3 hours, and repeat the extraction 3 times. After hot water extraction, cool and stand, freeze and centrifuge. The supernatant was concentrated by rotary evaporation to a certain volume. Add 95% ethanol solution until the final volume fraction of ethanol is 80%, let it stand overnight, centrifuge at 8000r / min at low temperature, take the precipitate, add a small amount of distilled water to dissolve, completely evaporate the residual alcohol by rotary evaporation, concentrate to a certain volume, and remove it by Sevage method. For protein, the operation was repeated 5 times, and the rotary evaporation ...

Embodiment 2

[0038](1) Extraction of polysaccharides from Ulva lobes: Wash a certain amount of Ulva lobes, control water, dry in an oven at 60°C, and cut into pieces. Add 95% ethanol solution to immerse and degrease, and let stand overnight. Take out the degreased Ulva sliver and dry it in the sun, add distilled water according to the ratio of solid to liquid 1:10, bathe in 95℃ water for 3 hours, and repeat the extraction 3 times. After hot water extraction, cool and stand, freeze and centrifuge. The supernatant was concentrated by rotary evaporation to a certain volume. Add 95% ethanol solution until the final volume fraction of ethanol is 80%, let it stand overnight, centrifuge at 8000r / min at low temperature, take the precipitate, add a small amount of distilled water to dissolve, completely evaporate the residual alcohol by rotary evaporation, concentrate to a certain volume, and remove it by Sevage method. For protein, the operation was repeated 5 times, and the rotary evaporation w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com