Lubricating oil flame-retardant antibacterial additive

An antibacterial additive and lubricating oil technology, applied in the field of lubricating oil, can solve problems such as single performance, achieve the effect of superior flame retardant and improve product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

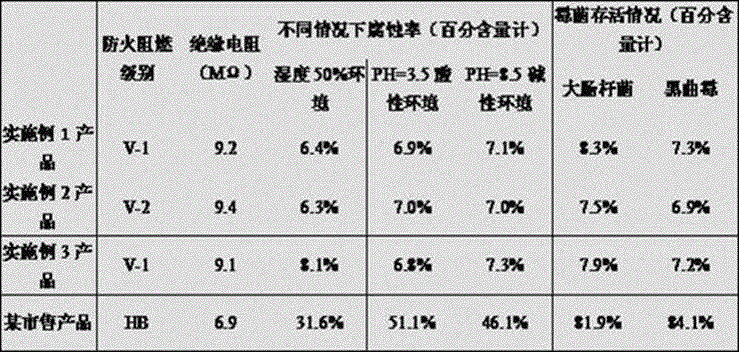

Embodiment 1

[0016] The lubricating oil flame retardant and antibacterial additive in the present embodiment is made up of the following components in mass parts: 30 parts of poly-4-methyl-1-pentene, 28 parts of pentaerythritol phosphate, 28 parts of urea formaldehyde resin, methyl acetate 26 parts of ester, 28 parts of ethylene oxide, 28 parts of dimethyl hydroxy silicone oil, 26 parts of tetraethyl silicate, 28 parts of modified hydrogenated castor oil, 28 parts of polyhexamethylene biguanide hydrochloride, didecyl 26 parts of dimethyl ammonium chloride, 26 parts of carbolic acid, 26 parts of calcium borate, 28 parts of aluminum carbonate powder, 26 parts of lead carbonate powder, 24 parts of potassium ferricyanate, 28 parts of bismuth tungstate powder, 26 parts of zinc oxide powder , 24 parts of rock wool, 26 parts of alumina powder, 24 parts of praseodymium oxide powder, 24 parts of PCB, 24 parts of decabromodiphenylethane, 22 parts of sodium antimonate powder, 18 parts of polyacrylonit...

Embodiment 2

[0022] The lubricating oil flame retardant and antibacterial additive in the present embodiment is made up of the following components in mass parts: 32 parts of poly-4-methyl-1-pentene, 30 parts of pentaerythritol phosphate, 30 parts of urea formaldehyde resin, methyl acetate 28 parts of ester, 30 parts of ethylene oxide, 30 parts of dimethyl hydroxy silicone oil, 28 parts of tetraethyl silicate, 30 parts of modified hydrogenated castor oil, 30 parts of polyhexamethylene biguanide hydrochloride, didecyl 28 parts of dimethyl ammonium chloride, 28 parts of carbolic acid, 28 parts of calcium borate, 30 parts of aluminum carbonate powder, 28 parts of lead carbonate powder, 26 parts of potassium ferricyanide, 30 parts of bismuth tungstate powder, 28 parts of zinc oxide powder , 26 parts of rock wool, 28 parts of alumina powder, 26 parts of praseodymium oxide powder, 26 parts of PCB, 26 parts of decabromodiphenylethane, 24 parts of sodium antimonate powder, 20 parts of polyacrylonit...

Embodiment 3

[0028] The lubricating oil flame retardant and antibacterial additive in the present embodiment is made up of the following components in mass parts: 34 parts of poly-4-methyl-1-pentene, 32 parts of pentaerythritol phosphate, 32 parts of urea formaldehyde resin, methyl acetate 30 parts of ester, 32 parts of ethylene oxide, 32 parts of dimethyl hydroxy silicone oil, 30 parts of tetraethyl silicate, 32 parts of modified hydrogenated castor oil, 32 parts of polyhexamethylene biguanide hydrochloride, didecyl 30 parts of dimethyl ammonium chloride, 30 parts of carbolic acid, 30 parts of calcium borate, 32 parts of aluminum carbonate powder, 30 parts of lead carbonate powder, 28 parts of potassium ferricyanide, 32 parts of bismuth tungstate powder, 30 parts of zinc oxide powder , 28 parts of rock wool, 30 parts of alumina powder, 28 parts of praseodymium oxide powder, 28 parts of PCB, 28 parts of decabromodiphenylethane, 26 parts of sodium antimonate powder, 22 parts of polyacrylonit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com