A kind of water-soluble polymer coated special-shaped silica sol, preparation method and application

A water-soluble polymer and silica sol technology, which is applied in chemical instruments and methods, other chemical processes, polishing compositions containing abrasives, etc., can solve the problems of high surface roughness and low polishing rate, and improve surface smoothness Degree, improve the effect of polishing removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The weight percentage of the raw materials of the water-soluble polymer-coated special-shaped silica sol in this embodiment consists of:

[0040] A, polypolyol, 0.01g, molecular weight is between 200-400; Described polypolyol is polyethylene glycol;

[0041] b. Water-soluble polymer, 0.01g, molecular weight between 10000-10200; the water-soluble polymer is polyacrylamide;

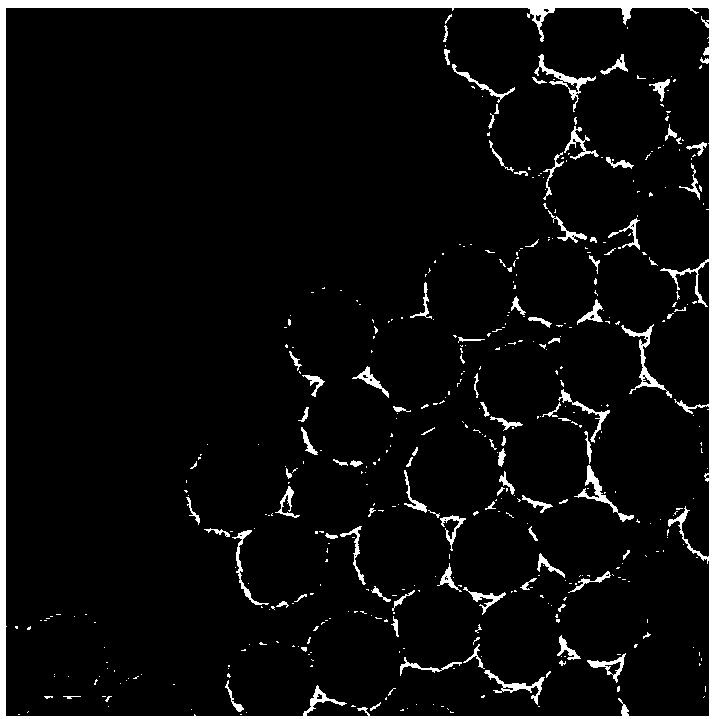

[0042]C, silica sol raw material, 20g; The average particle diameter of described silica sol raw material is 55nm, and solid content is 5wt%, and the transmission electron microscope photo of this silica sol raw material is as follows figure 1 shown;

[0043] d. The balance is deionized water.

[0044] The preparation process is as follows:

[0045] 1) under 150rpm rotation speed stirring, polypolyol and water-soluble polymer solid powder are respectively completely dissolved in deionized water, respectively to obtain polypolyol and water-soluble polymer aqueous solution;

[0046] 2) Add the sili...

Embodiment 2

[0061] The weight percentage of the raw materials of the water-soluble polymer coated special-shaped silica sol in this embodiment consists of: 0.1g polyethylene glycol (molecular weight 5000-5500), 0.10g polyacrylamide (molecular weight 250000-250200), 20g silica sol raw material (average particle size 100nm, solid content is 50wt%) and the balance of deionized water.

[0062] The preparation process is the same as in Example 1, except that the control speed is 200rpm throughout the preparation process, and the silica sol raw material needs to be diluted 2 times before adding the silica sol raw material dropwise to the aqueous solution of polyethylene glycol in step 2). Then it was added dropwise to an aqueous solution of polyethylene glycol.

[0063] Use the water-soluble polymer-coated special-shaped silica sol in this embodiment as an abrasive to prepare a sapphire substrate polishing solution. The preparation process is as follows: Take 50 g of the above-mentioned water-s...

Embodiment 3

[0075] The weight percentage of the raw materials of the water-soluble polymer coated special-shaped silica sol in this embodiment consists of: 1g polypropylene glycol (molecular weight 19000-20000), 5g polyacrylamide (molecular weight 491000-500000), 20g silica sol raw material (average particle diameter 150nm, Solid content is 20wt%) and deionized water of balance.

[0076] The preparation process is the same as in Example 2, except that the silica sol raw material needs to be diluted 1 times before adding the silica sol raw material dropwise to the aqueous solution of polyethylene glycol in step 2), and then added dropwise to the polyethylene glycol solution. in aqueous solution.

[0077] Use the water-soluble polymer-coated special-shaped silica sol in this example as an abrasive to prepare a sapphire substrate polishing solution. The preparation process is as follows: Take 50 g of the above-mentioned water-soluble polymer-coated special-shaped silica sol, and mix it with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com