A kind of magnesium ferrite based magnetic dielectric material and preparation method thereof

A magnesium ferrite and magnetic medium technology, applied in the field of magnesium ferrite-based magnetic medium materials and its preparation, can solve the problems of limiting antenna size, affecting antenna performance, high magnetic permeability and permittivity, and improving radiation Efficiency and bandwidth, low dielectric properties, and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

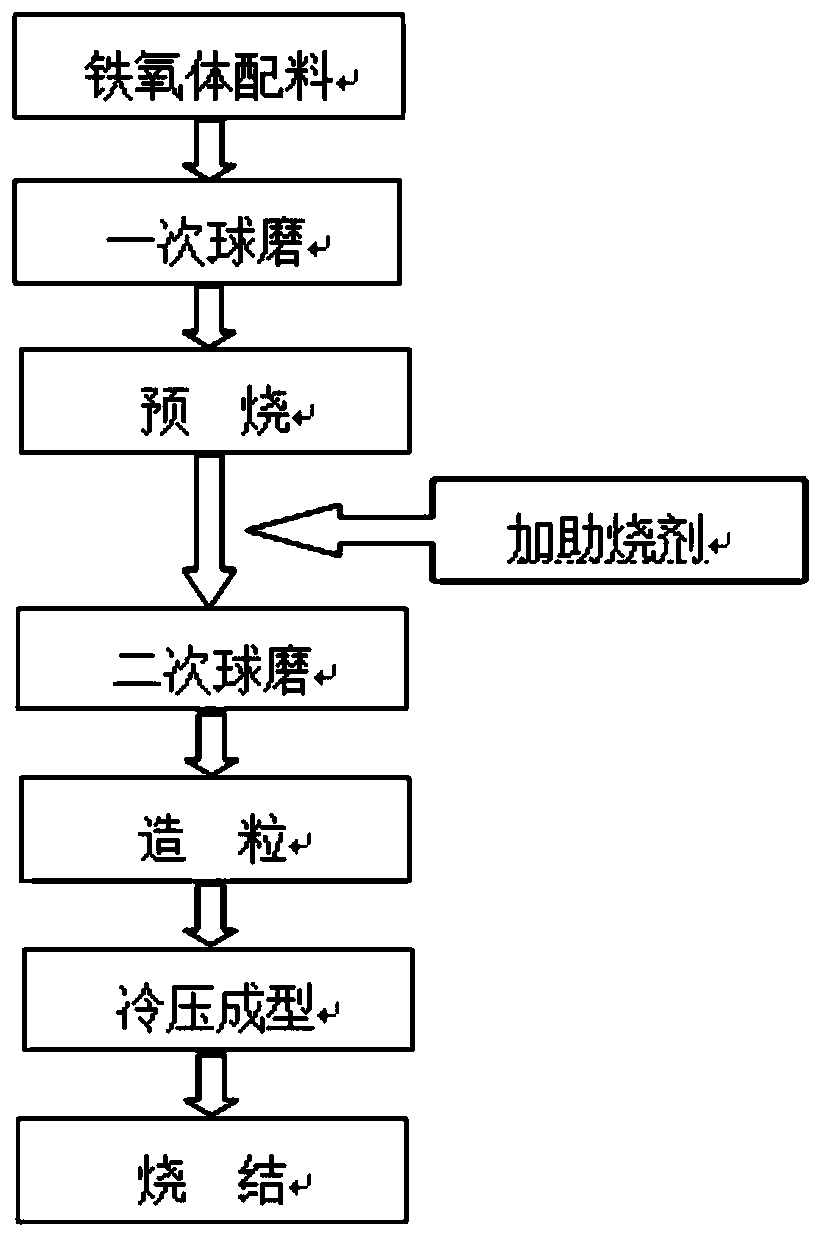

Method used

Image

Examples

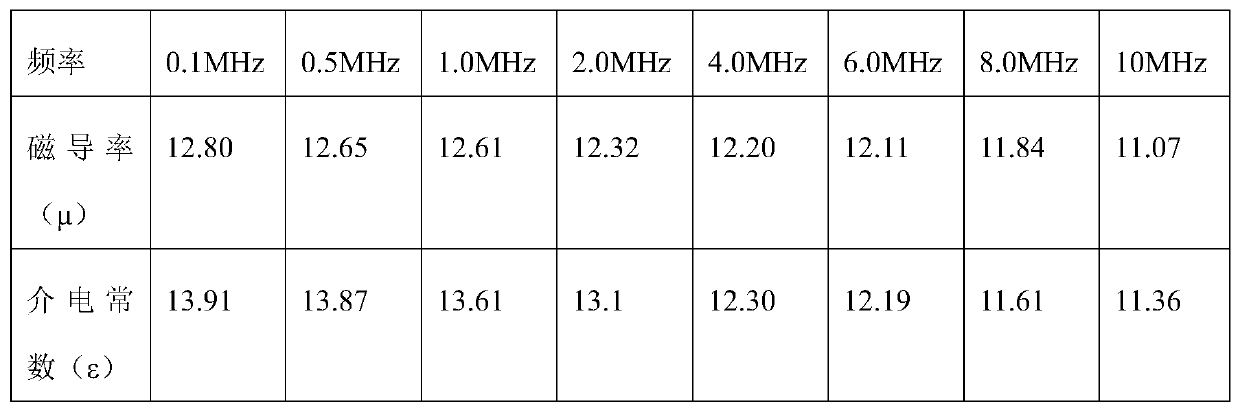

Embodiment 1

[0021] A method for preparing a magnesium ferrite-based magnetic dielectric material, comprising the following steps:

[0022] Step 1: Magnesium oxide (MgO), cadmium oxide (CdO) and iron oxide (Fe 2 o 3 ) as raw material, according to the main phase material Mg 1- x Cd x Fe 2 o 4 The proportion of metal elements in (x=0.1) is converted into MgO, CdO and Fe 2 o 3 After weighing 7.2g of magnesium oxide, 2.56g of cadmium oxide, and 32.0g of iron oxide, they were wet-milled in a planetary ball mill for 18 hours at a speed of 220 rpm, and the ball-milling medium was deionized water;

[0023] Step 2: Sieve the primary ball mill drying material obtained in step 1 and compact it in a sintered crucible, raise the temperature to the pre-calcination temperature at a rate of 2°C / min for pre-calcination, and naturally cool to room temperature with the furnace to obtain ferrite Pre-burn the powder; the pre-fire temperature is 1050°C, and the holding time is 4h;

[0024] Step 3: Add...

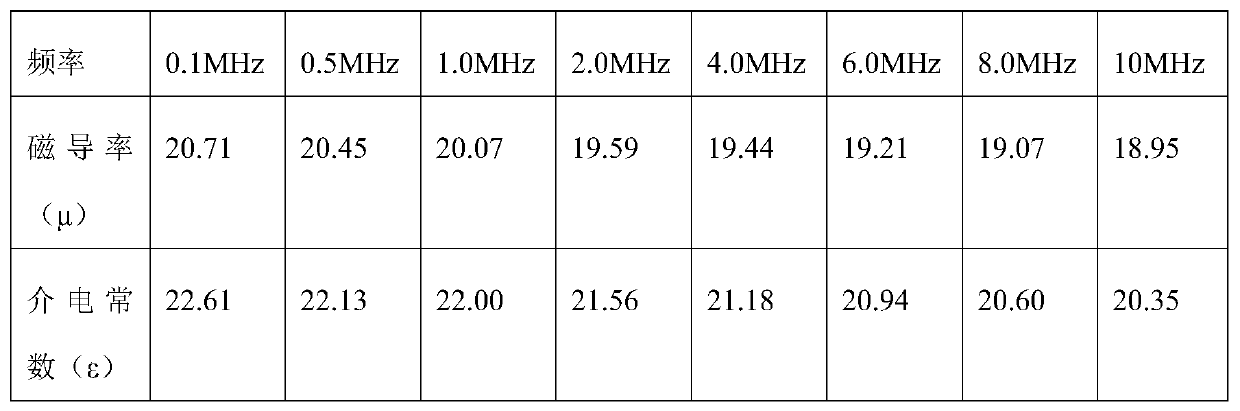

Embodiment 2

[0029] A method for preparing a magnesium ferrite-based magnetic dielectric material, comprising the following steps:

[0030] Step 1: Magnesium oxide (MgO), cadmium oxide (CdO) and iron oxide (Fe 2 o 3 ) as raw material, according to the main phase material Mg 1- x Cd x Fe 2 o 4 The proportion of metal elements in (x=0.2) is converted into MgO, CdO and Fe 2 o 3 After weighing 6.4g of magnesium oxide, 5.12g of cadmium oxide, and 32.0g of iron oxide, they were wet-milled in a planetary ball mill for 18 hours at a speed of 220 rpm, and the ball-milling medium was deionized water;

[0031] Step 2: Sieve the primary ball mill drying material obtained in step 1 and compact it in a sintered crucible, raise the temperature to the pre-calcination temperature at a rate of 2°C / min for pre-calcination, and naturally cool to room temperature with the furnace to obtain ferrite Pre-burn the powder; the pre-fire temperature is 1100°C, and the holding time is 4h;

[0032] Step 3: Add...

Embodiment 3

[0037] A method for preparing a magnesium ferrite-based magnetic dielectric material, comprising the following steps:

[0038] Step 1: Magnesium oxide (MgO), cadmium oxide (CdO) and iron oxide (Fe 2 o 3 ) as raw material, according to the main phase material Mg 1- x Cd x Fe 2 o 4 The proportion of metal elements in (x=0.3) is converted into MgO, CdO and Fe 2 o 3 After weighing 5.6g of magnesium oxide, 7.68g of cadmium oxide, and 32.0g of iron oxide, they were wet-milled in a planetary ball mill for 18 hours at a speed of 220 rpm, and the ball-milling medium was deionized water;

[0039] Step 2: Sieve the primary ball mill drying material obtained in step 1 and compact it in a sintered crucible, raise the temperature to the pre-calcination temperature at a rate of 2°C / min for pre-calcination, and naturally cool to room temperature with the furnace to obtain ferrite Pre-burn the powder; the pre-fire temperature is 1100°C, and the holding time is 4h;

[0040] Step 3: Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com