Super-elevation pumping marine concrete and preparation method thereof

A marine concrete and pumping technology, applied in the field of building materials, can solve problems such as segregation, pipe plugging, reduced service life, and degradation of concrete bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

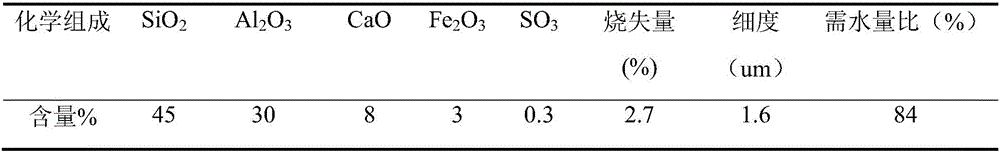

[0050] The preparation method of the hydration temperature rise regulating material described in Examples 1-3 comprises the following steps:

[0051] 1) Grinding the cassava, placing the ground product in clear water, allowing it to settle, and then placing the precipitate in a magnesium sulfate solution with a concentration of 10 wt% for 2 hours, and filtering to obtain starch;

[0052] 2) Dissolve the starch obtained in step 1) in water and stir evenly to form a starch slurry, adjust the pH value to 6.3, place it in a water bath at 60° C., and react in a water bath under stirring conditions for 2.5 hours until the starch slurry is completely gelatinized, and cool naturally. Obtain starch colloid;

[0053] 3) The starch colloid obtained in step 2) was placed in a vacuum drying oven and heated to 150°C at a rate of 5°C / min, kept for 15 minutes, and cooled naturally to obtain hydration temperature rise control material component A;

Embodiment 1~3

[0073] The ultra-elevation pumping marine concrete described in Examples 1 to 3 is prepared with cement (C), fly ash (FA), slag powder (BFS), river sand (S), crushed stone (G), hydration temperature It is made from HHCM, corrosive ion transport inhibitor (CITI), state modified material (SMM), ultra-dispersed water-reducing, shrink-reducing and plastic-preserving admixture (JNT) and water. The preparation method includes the following Steps: Weigh each raw material according to the mixing ratio, pour cement, fly ash, mineral powder, gravel and river sand into the concrete mixer and dry mix for 3 minutes, fully dry mix evenly, then add water, corrosive ion transport inhibitor, The ultra-dispersed water-reducing, shrink-reducing, and plastic-preserving admixture is stirred continuously for 10 to 15 minutes to obtain the super-elevation pumping marine concrete.

Embodiment 1

[0075] According to Table 1-1, the raw materials are weighed to prepare C40 super-elevation pumping marine concrete. The working performance and mechanical performance test results of the super-elevation marine concrete obtained in this embodiment and the obtained marine concrete in the comparative example are shown in Table 1-2. The test results of volume stability, crack resistance and durability are shown in Table 1-3.

[0076] Table 1-1 C40 ultra-elevation pumping marine concrete mix ratio (unit: kg / m 3 )

[0077]

[0078] In Table 1-1, the PC is Jiangsu Bote polycarboxylate superplasticizer with a solid content of 40% and a water reducing rate of 25%.

[0079] Table 1-2 Working performance and mechanical properties of C40 super-elevation pumping marine concrete obtained in Example 1

[0080]

[0081] Table 1-3 The volume stability, crack resistance and durability of the C40 super-elevation pumping marine concrete obtained in Example 1

[0082]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com