Automatic aluminum alloy plate welding equipment with acetone cleaning device

A cleaning device, a technology for aluminum alloy plates, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of high thermal crack tendency, inappropriate parameters, decreased joint performance, etc. , The welding seam is smooth and beautiful, and the effect of reducing the critical current value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

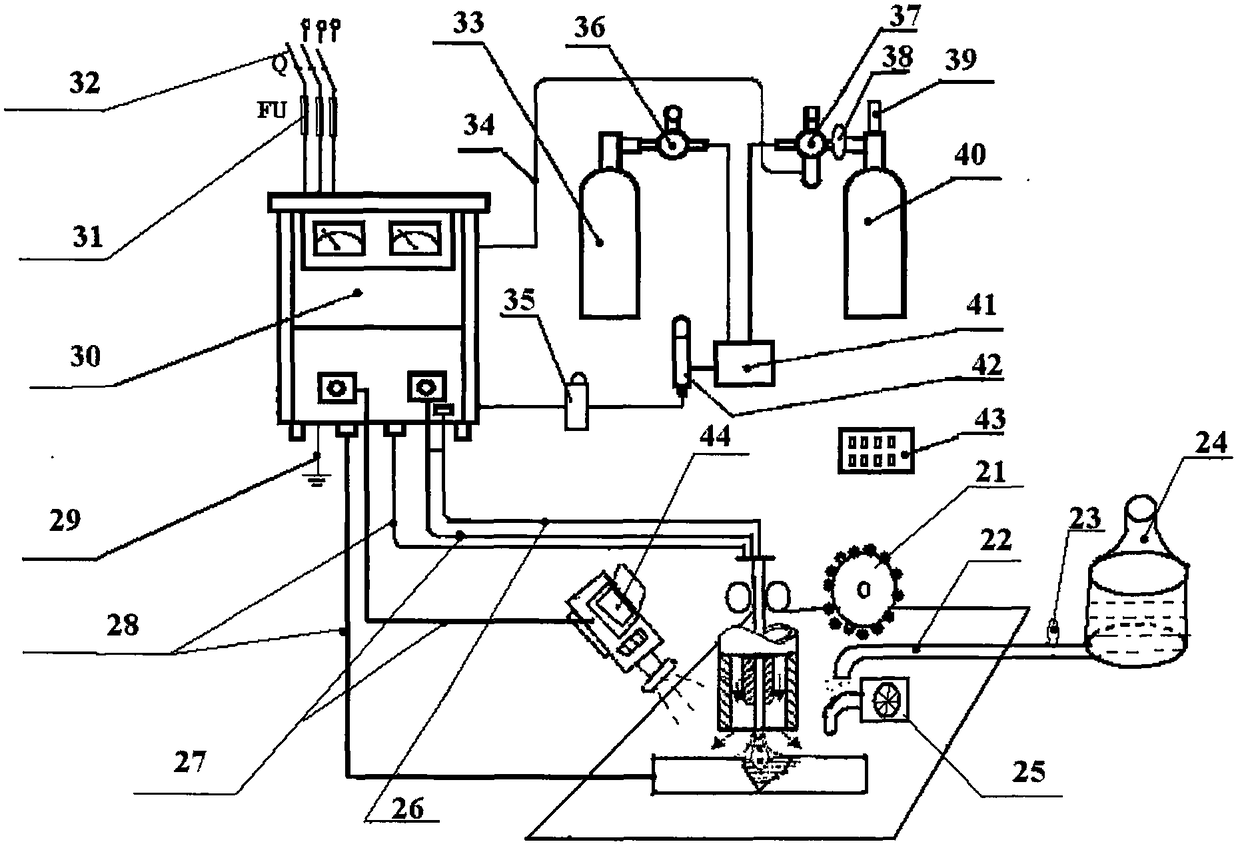

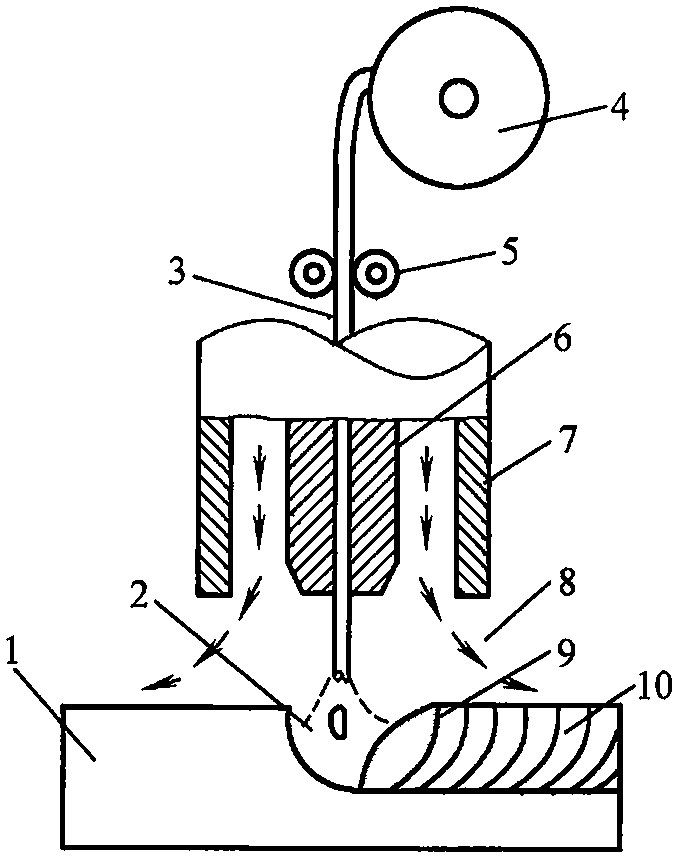

[0028] Such as figure 1As shown, firstly, a 35-degree groove is opened at the welding place of the aluminum alloy thick plate to be welded. And the weldment 1 is clamped on the pneumatic fixture, and then the oxide film and other impurities in the weld area are cleaned in time with the stainless steel brush 21, and then the aluminum alloy to be welded is sprayed with the acetone spray pipe 22. The weldment 1 is clamped on the pneumatic fixture, and the pneumatic fixture is installed on the transmission platform. The transmission platform moves forward continuously, and the aluminum alloy to be welded is cleaned by the stainless steel brush 21 in time to remove the oxide film, Acetone is sprayed, moisture and acetone are blown dry by the electric heating blower 25, welded, and the welding live scene is captured by the CCD camera 44 during the welding process and is transmitted to the control system by the control line 27, and the pulse frequency and welding torch are adjusted i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com