Preparing method for load magnetic metal sepiolite composite powder or fiber

A sepiolite fiber and magnetic metal technology, applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problems of insignificant absorption effect, high density, narrow absorption frequency band, etc., and achieve easy magnetic loss matching characteristics, Simple preparation method and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

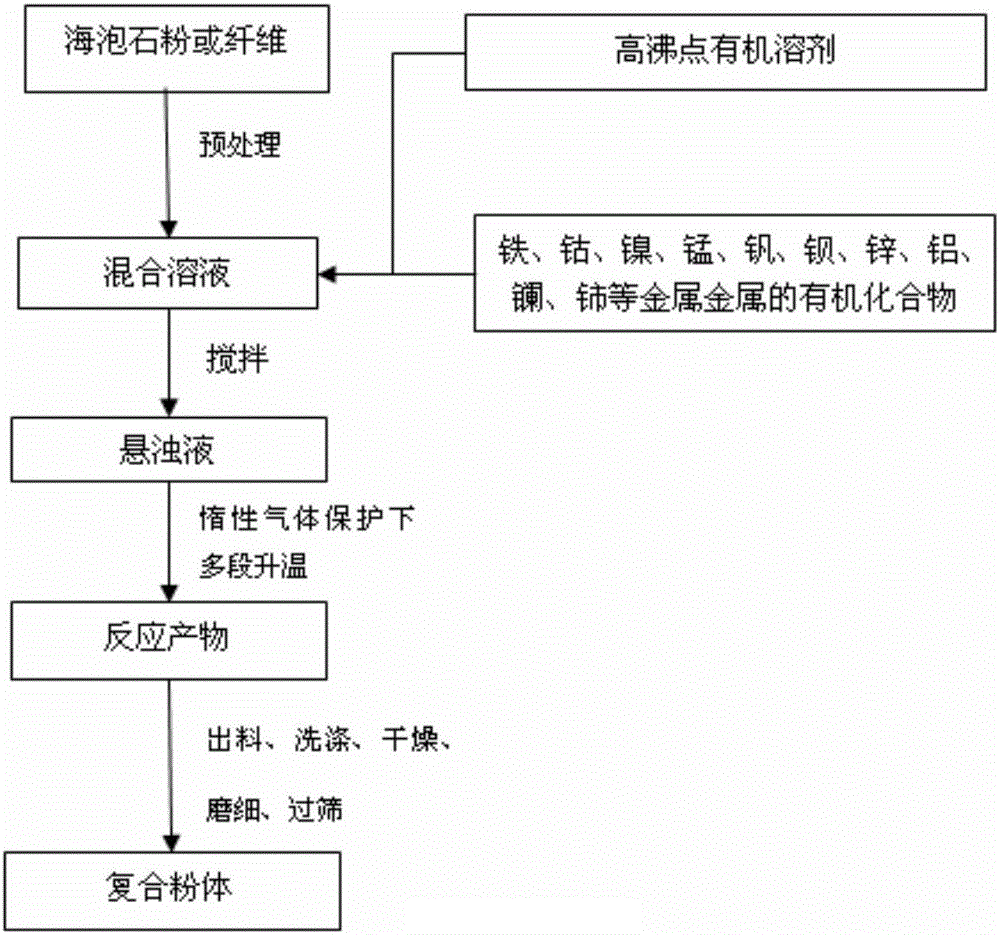

Method used

Image

Examples

Embodiment 1

[0043] After burning the sepiolite powder in an oven at 120° C. for 12 hours, cooling, grinding, and passing through a 200-mesh sieve, the pretreated sepiolite powder was obtained. Using xylene as an organic solvent, a metal-organic solution system is prepared with carbonyl iron in a solution system with a mass percentage of 50%, and added to a 20L reactor with a filling capacity of 50%, and the pretreated Sepiolite powder. Close the reactor, feed nitrogen, and remove the oxygen in the reactor. Set up a 3-stage heating program: (1) from room temperature to 100°C in 120 minutes, (2) from 100°C to 120°C in 540 minutes, (3) from 120°C to 135°C in 240 minutes. Then the temperature is lowered to room temperature, and the material is discharged. The obtained material is washed with absolute ethanol, filtered, dried, ground, and sieved to obtain a reaction product, which is a sepiolite fiber composite powder loaded with magnetic metal iron.

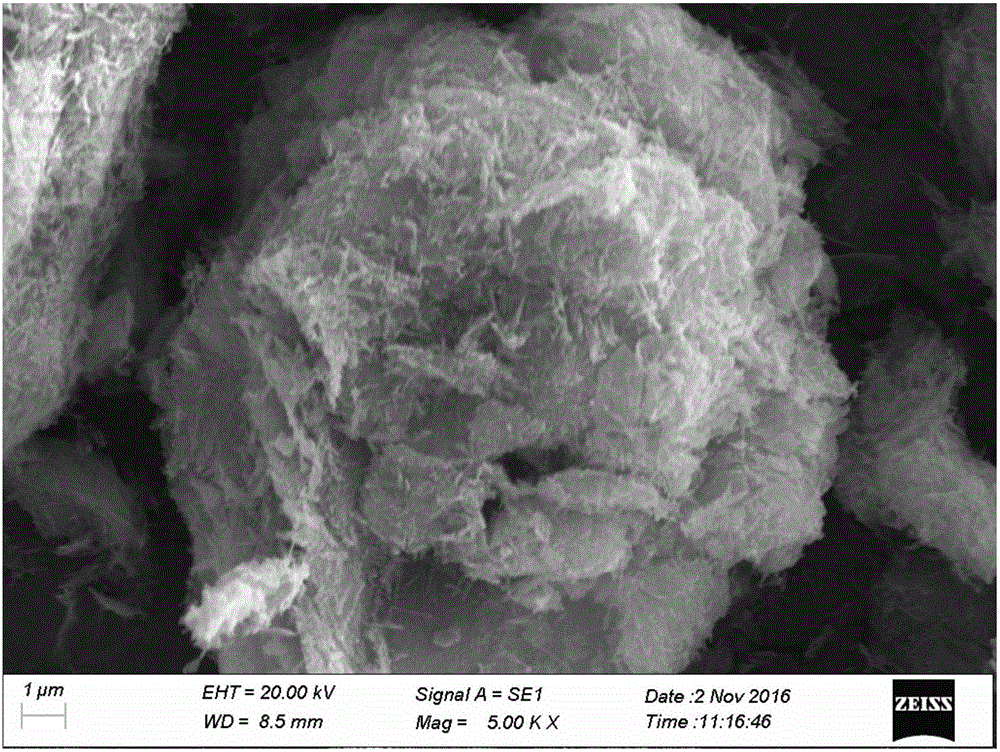

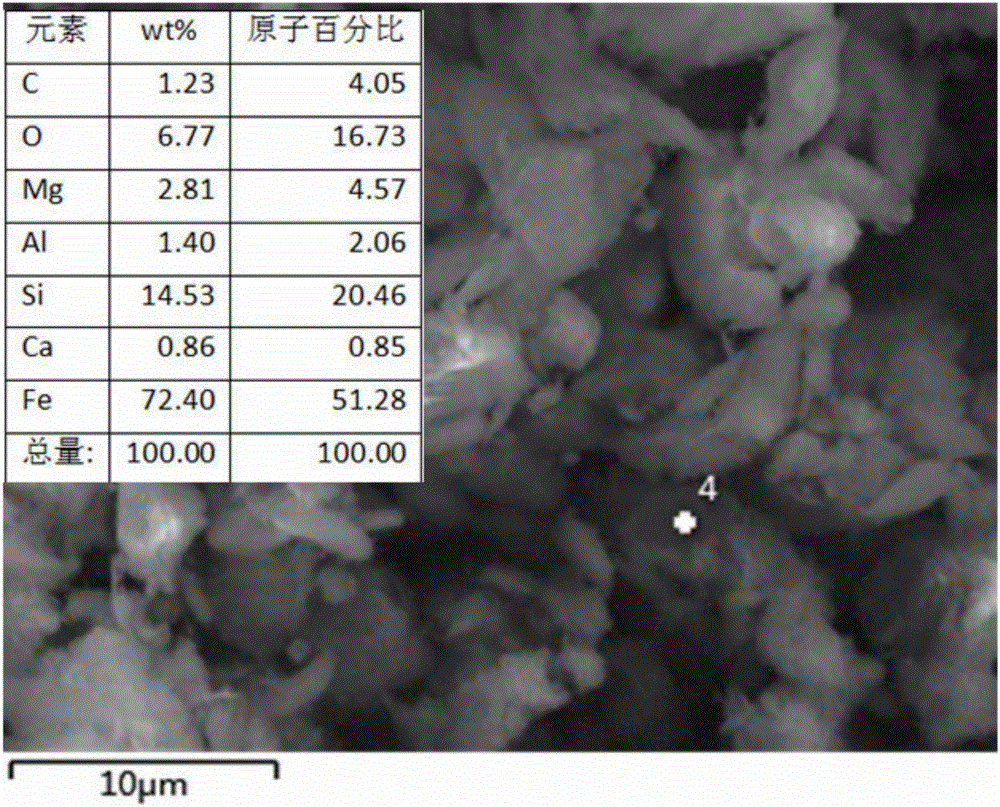

[0044] It can be seen from the attached...

Embodiment 2

[0047] After burning the sepiolite powder in an oven at 120° C. for 12 hours, cooling, grinding, and passing through a 200-mesh sieve, the pretreated sepiolite powder was obtained. Xylene is an organic solvent, carbonyl iron and carbonyl cobalt are mixed at a mass percentage of 1:1, and a mixture of pentacarbonyl iron and octacarbonyl dicobalt is configured in a solution system with a mass percentage of 50% to prepare a metal-organic solution system and add it to a 20L reaction In the kettle, the filling amount is 50%, and the pretreated sepiolite powder is added with a liquid-solid ratio of 4. Close the reactor, feed nitrogen, and remove the oxygen in the reactor. Set up a 3-stage heating program: (1) from room temperature to 100°C in 120 minutes, (2) from 100°C to 120°C in 540 minutes, (3) from 120°C to 135°C in 240 minutes. Then the temperature is lowered to room temperature, and the material is discharged. The obtained material is washed with absolute ethanol, filtered, d...

Embodiment 3

[0049] Prepare a 95% ethanol solution of silane coupling agent (KH550) with a concentration of 0.5mmol / L, add sepiolite fibers to the 95% ethanol solution of silane coupling agent according to the liquid-solid ratio of 3, stir at 20°C for 60min, then wash and filter , dried at 120°C for 2 hours, cooled, ground, and sieved to obtain pretreated sepiolite fibers. Quinoline is an organic solvent, and nickel tetracarbonyl and dimanganese decacarbonyl are mixed at a mass percentage of 2.6:1, and the mixture of nickel tetracarbonyl and dimanganese decacarbonyl is configured in a solution system with a mass percentage of 30% to form a metal-organic solution system, and is added to In the 20L reactor, the filling amount is 50%, and the pretreated sepiolite powder is added at a liquid-solid ratio of 8. Close the reactor, feed nitrogen, and remove the oxygen in the reactor. Set up a 3-stage heating program: (1) from room temperature to 150°C in 240 minutes, (2) from 150°C to 200°C in 48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com