A high temperature resistant antenna

A technology of high temperature resistance and antenna, which is applied to antennas, antenna parts, antennas suitable for movable objects, etc., can solve the problems of difficult application of millimeter wave band, non-negligible antenna loss in high frequency band, large antenna loss, etc., to achieve strong Practicality and application prospects, stable and reliable electrical performance, and the effect of meeting high temperature resistance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] based on the following Figure 1 to Figure 6 , specifically explain the preferred embodiment of the present invention.

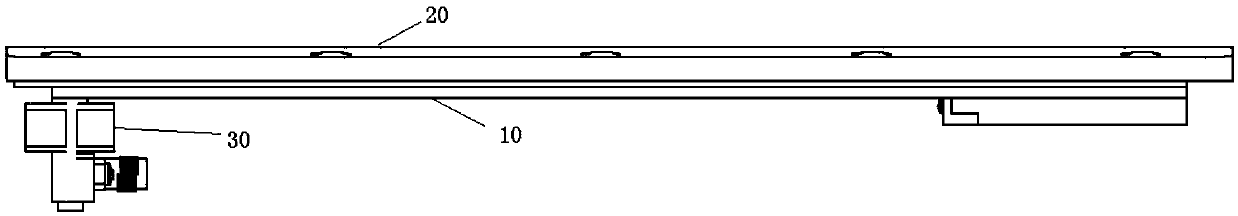

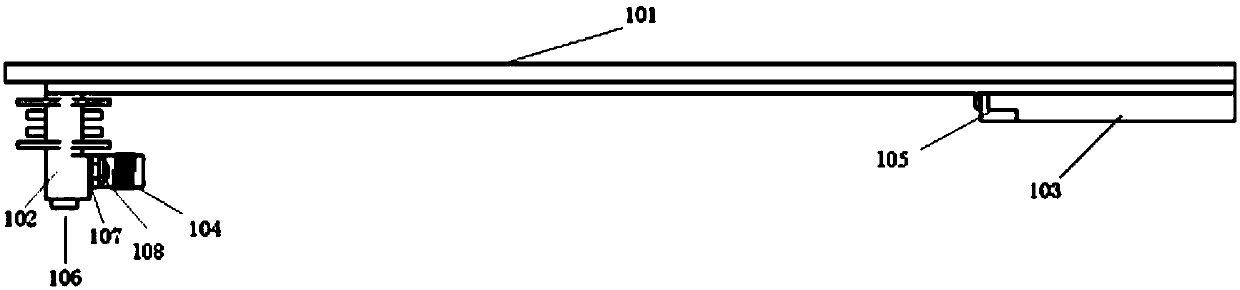

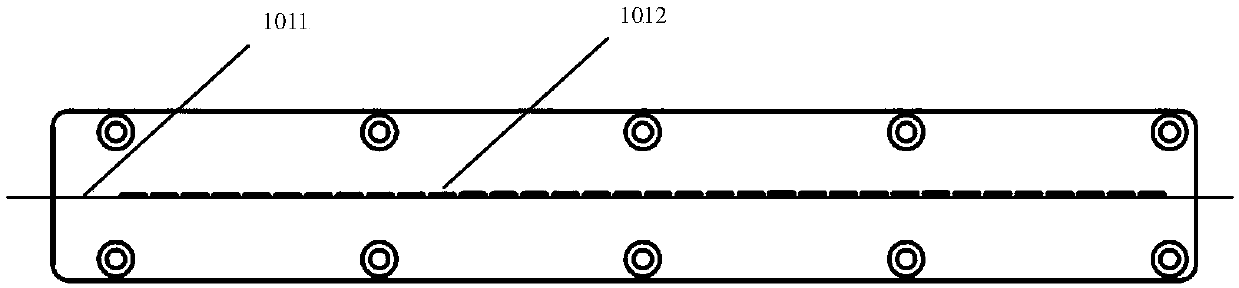

[0046] Such as figure 1 As shown, the present invention provides a high-temperature-resistant antenna, including: an antenna body 10, a radome 20 installed outside the antenna body 10, and a heat capacity expansion container 30 arranged on the antenna body 10. The antenna body 10 is used for Radiating electromagnetic waves and receiving electromagnetic wave echoes from the target, the radome 20 completely covers the antenna body 10 mounted on the carrier, avoiding the antenna being directly exposed to high-speed airflow, and protecting the antenna body 10 from the influence of external heat flow, It has the function of heat insulation and wave penetration, and meets the aerodynamic requirements. The heat capacity expander 30 is used to expand the heat capacity of the fuze and reduce the temperature rise rate of the antenna body 10 .

[0047] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com