Method for packaging metal coated fiber grating

A technology of fiber grating and packaging method, which is applied in the direction of mitigating undesired effects, instruments, etc., and can solve the problem of the lack of reports on metal-coated fiber grating packaging technology, the brittle working life of glue media, and the difficulty in meeting the application of spaceborne devices To achieve the effect of ensuring the consistency of the process, improving the radiation resistance and mechanical strength, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A metal-coated optical fiber grating packaging method of the present invention comprises the following steps:

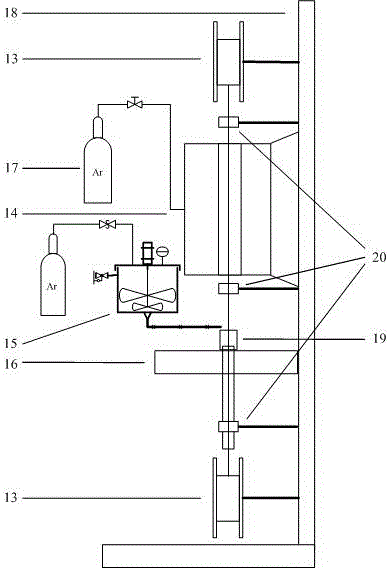

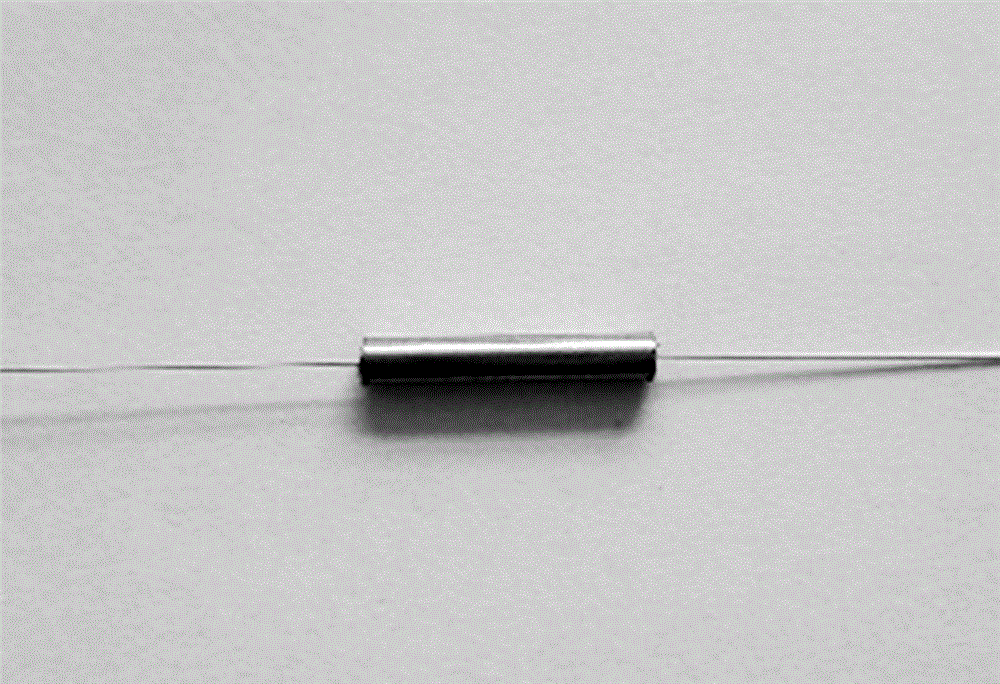

[0023] 1. Design of stainless steel tube with variable inner diameter: as shown in Figure-1, the outer diameter of the stainless steel sleeve is 1.5mm, and the inner diameter of the small diameter part in the middle is 0.18mm~0.2mm (the diameter of the metal-coated optical fiber is about 0.15mm), which is used to nest the bare fiber grating The fiber part; the inner diameter of both ends of the stainless steel sleeve is 1.3mm, which is used to fill the adhesive;

[0024] 2. Low-temperature glass frit treatment: Pour low-temperature glass frit (softening point around 380°C) and high-purity ethanol into a stirring container, stir thoroughly to obtain pasty low-temperature glass, which is used as an adhesive for optical fiber grating materials and metal tubes;

[0025] 3. Adjust the supporting metal tube (with an inner diameter greater than 0.3mm and an outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com