Electrochemical polishing electrolyte and polishing method for titanium and titanium alloy

An electrochemical and titanium alloy technology, applied in the field of electrochemical polishing electrolyte and polishing, can solve the problems of difficult large-scale application under low temperature conditions, easy corrosion on the surface of the sample, difficulty in obtaining polishing effect, etc. Good specular effect, avoid low temperature and relatively high voltage or high current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the electrochemical polishing electrolyte and the polishing method thereof of the present invention are used to electrochemically polish the surface of the titanium alloy, and the Zeiss sigma high-resolution scanning electron microscope of German Zeiss Company is used to observe the microscopic surface morphology of the titanium alloy. The specific steps as follows:

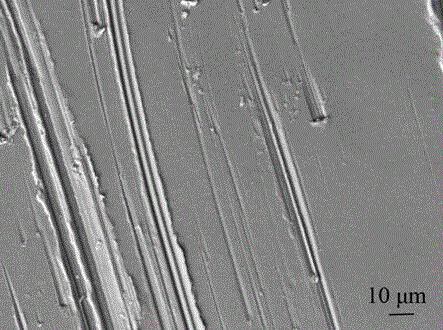

[0046] S1. Pretreatment: Polish the titanium alloy with a size of 10mm×10mm×2mm with metallographic sandpaper of 320 mesh, 500 mesh, 800 mesh, 1500 mesh and 2000 mesh in sequence, then wash it with deionized water and dry it; figure 1 is the SEM image of titanium alloy after pretreatment, from figure 1 Scratches left by hand polishing can be clearly seen in the middle;

[0047] S2. Surface degreasing and pickling treatment: Ultrasonic degreasing is performed on the product of S1 with acetone solution, then cleaned with deionized water, then pickled in a mixed solution of nitric acid an...

Embodiment 2

[0052] In this embodiment, the electrochemical polishing electrolyte and polishing method thereof of the present invention are used to electrochemically polish the surface of pure titanium, and the surface microscopic appearance of pure titanium is observed with a Zeiss sigma high-resolution scanning electron microscope from Zeiss, Germany. The specific steps as follows:

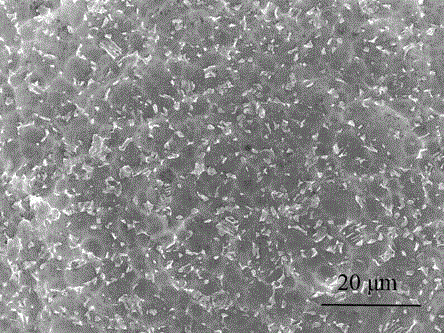

[0053] S1. Pretreatment: Polish the pure titanium with a size of 10mm×10mm×2mm with metallographic sandpaper of 320 mesh, 500 mesh, 800 mesh, 1500 mesh and 2000 mesh in sequence, then wash it with deionized water and dry it; Figure 7 is the SEM picture of pure titanium after pretreatment, from Figure 7 Scratches left by hand polishing can be clearly seen in the middle;

[0054] S2. Surface degreasing and pickling treatment: Ultrasonic degreasing is performed on the product of S1 with alcohol solution, then cleaned with deionized water, then pickled in a mixed solution of nitric acid and hydrofluoric acid,...

Embodiment 3

[0059] In this embodiment, the electrochemical polishing electrolyte and the polishing method thereof of the present invention are used to electrochemically polish the surface of the titanium alloy, and the Zeiss sigma high-resolution scanning electron microscope of German Zeiss Company is used to observe the microscopic surface morphology of the titanium alloy. The specific steps as follows:

[0060] S1. Pretreatment: Polish the titanium alloy with a size of 10mm×10mm×2mm with metallographic sandpaper of 320 mesh, 500 mesh, 800 mesh, 1500 mesh and 2000 mesh in sequence, then wash it with deionized water and dry it;

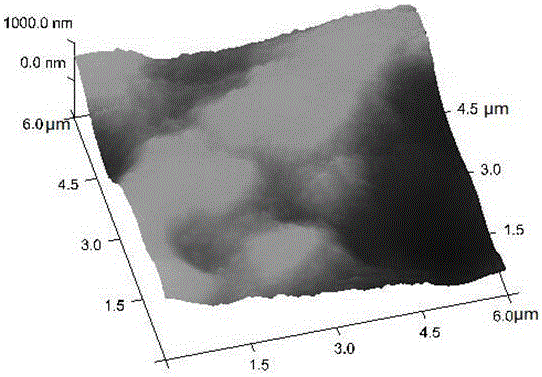

[0061] S2. Surface degreasing and pickling treatment: Ultrasonic degreasing is performed on the product of S1 with acetone solution, then cleaned with deionized water, then pickled in a mixed solution of nitric acid and hydrofluoric acid, and then cleaned with deionized water , blow dry; the surface of the treated titanium alloy is uneven, and the roughness is 46...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com