Preparing method for polystyrene microsphere loaded nano-copper composite material

A technology of polystyrene microspheres and composite materials, applied in the field of composite materials, can solve the problems of polystyrene microsphere-loaded nano-copper composite materials, complex and difficult control of polystyrene microspheres, and the like. Stable properties, easy control of reaction conditions and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

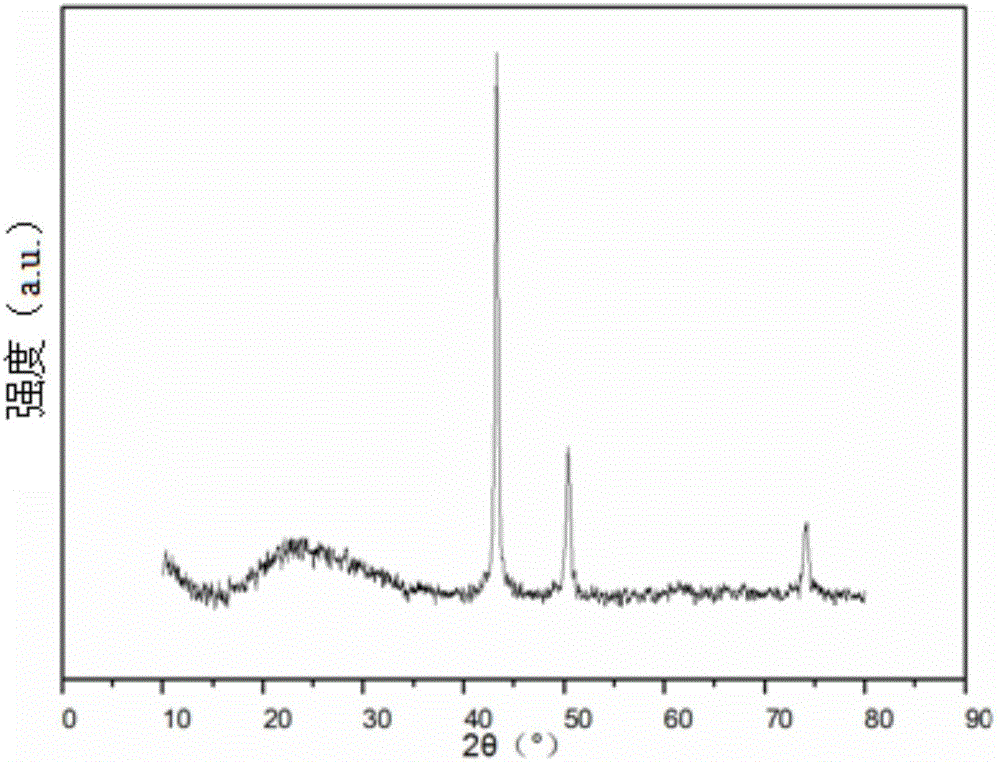

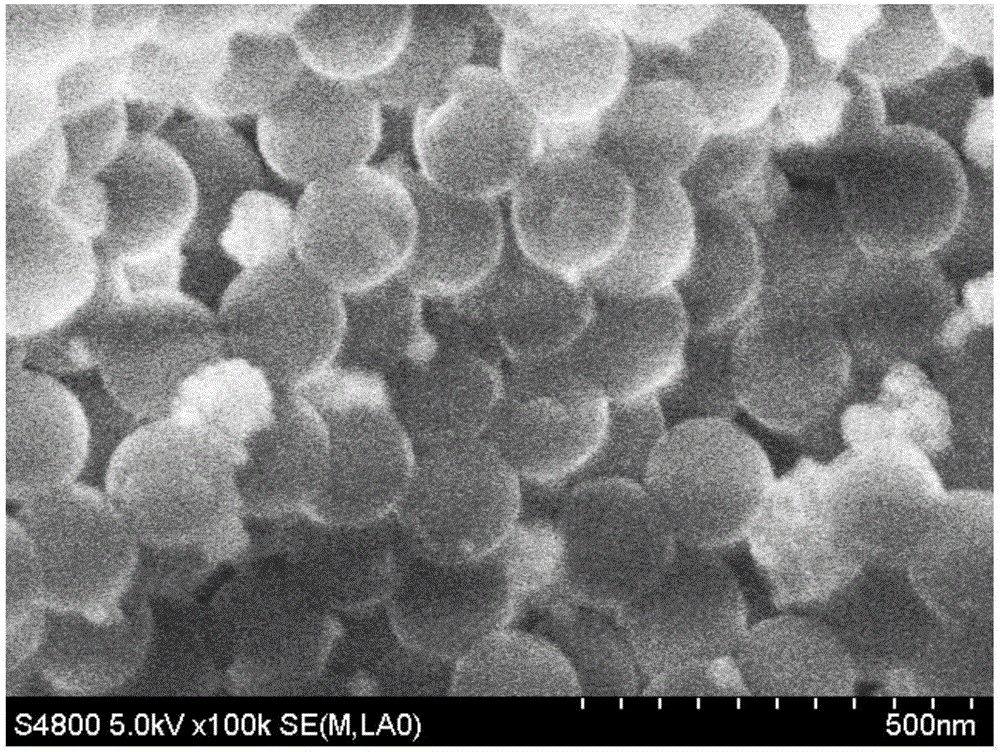

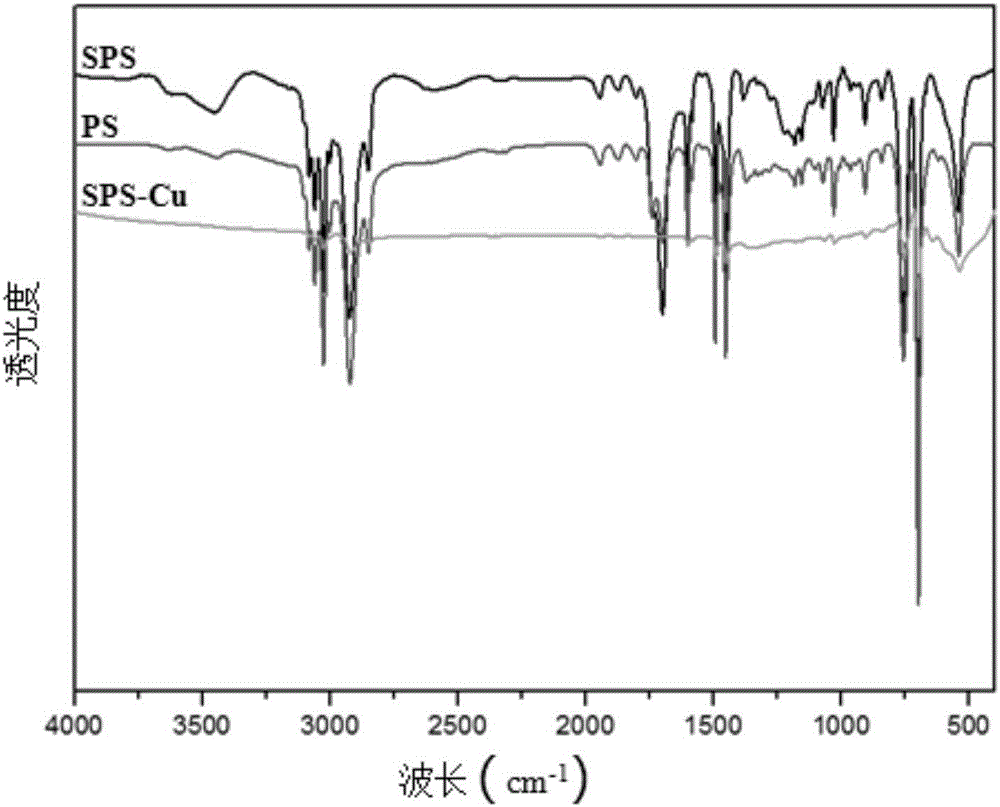

[0023] Specific embodiment one: the preparation method of polystyrene microsphere-loaded nano-copper composite material in this embodiment is carried out according to the following steps:

[0024] Step 1. Add 0.5g of sodium dodecylbenzene sulfonate to 500°C deionized water, add 25mL of styrene and 5mL of divinylbenzene under stirring conditions, pass in nitrogen, and add 0.5mL when the reaction temperature is 80°C g potassium persulfate, continue to react with nitrogen for 12 hours, after the reaction is over, cool, centrifuge, take the lower layer of solid, wash with deionized water until there is no unreacted monomer, and disperse with 10mL of deionized water;

[0025] Step 2, then add 30mL concentrated sulfuric acid, mix well, heat and react at 45°C for 10h, then dilute with deionized water to obtain a milky white suspension, wash with deionized water until neutral, and then use 30mL deionized water for ultrasonic dispersion ( Polystyrene microspheres have sulfonic acid gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com