Ultraviolet detector and preparation method thereof

A detector and ultraviolet light technology, applied in the field of photoelectric detection, to achieve good light response, mild reaction conditions, and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

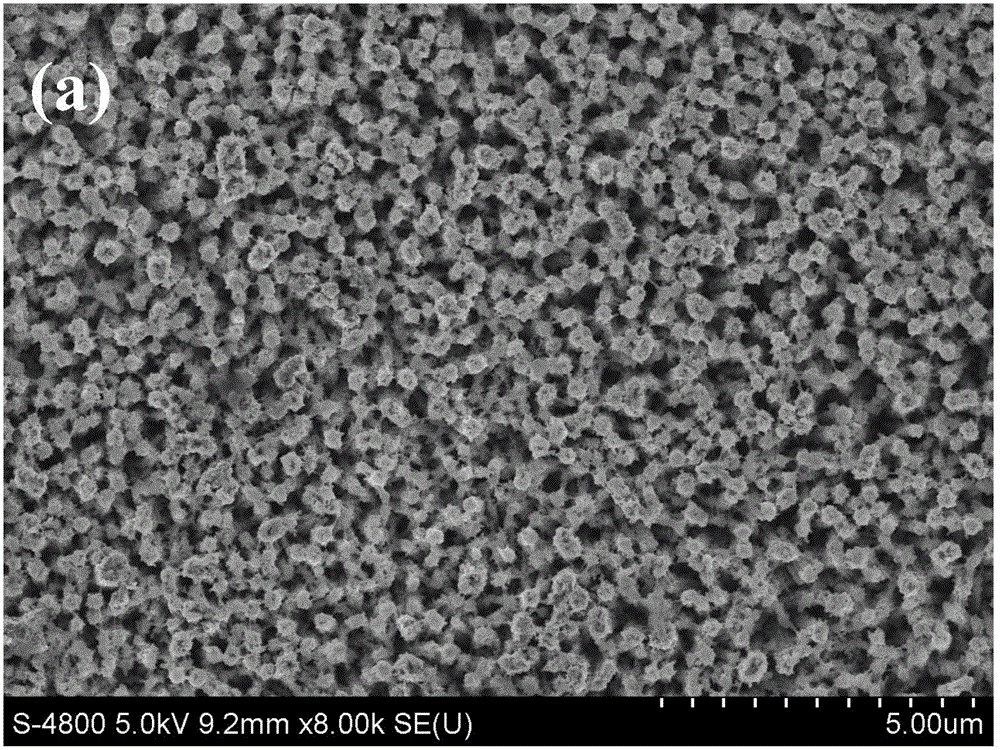

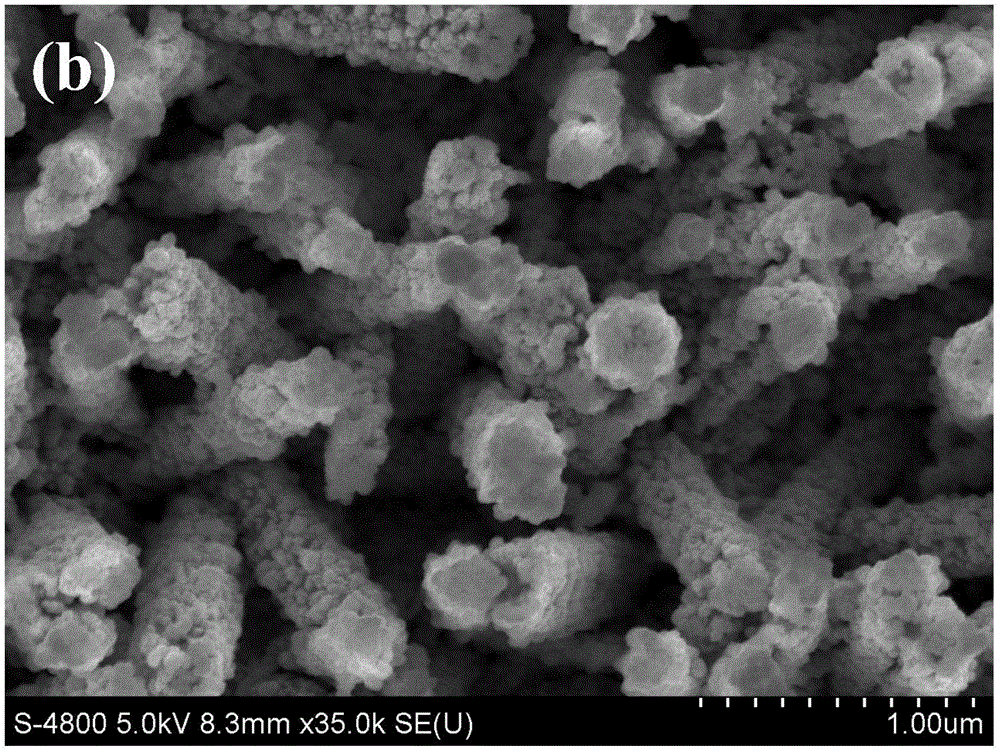

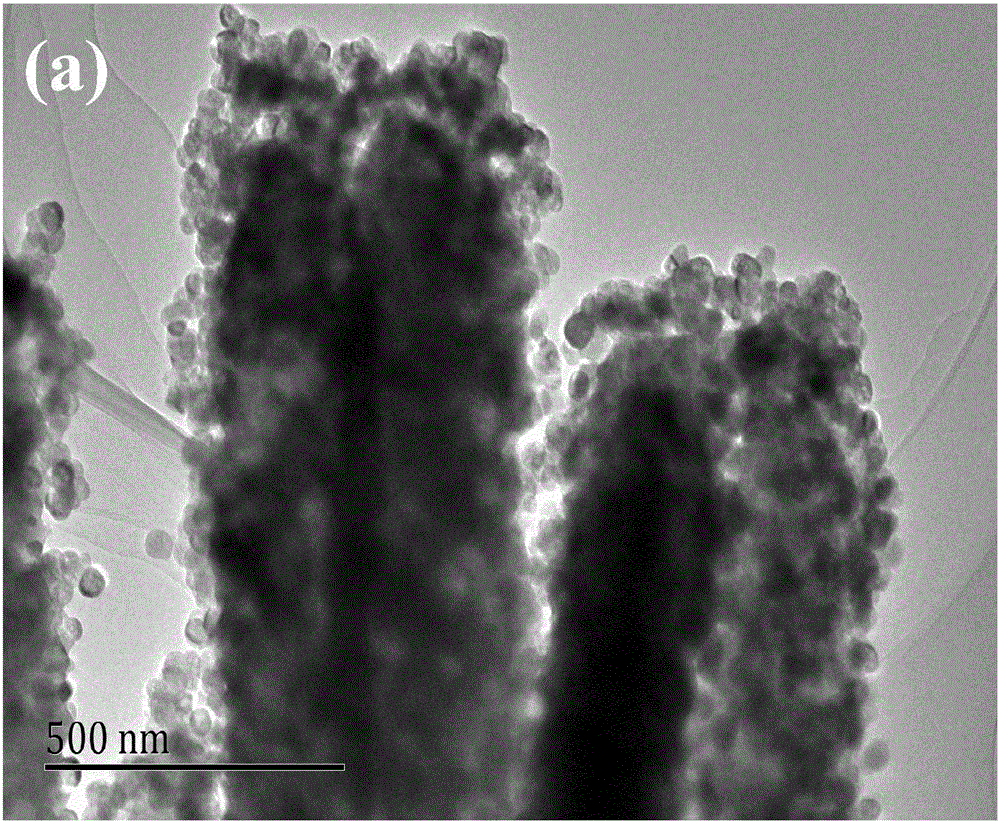

[0035] Firstly, place the 1cm×1cm quartz substrate in acetone, ethanol and deionized aqueous solution for ultrasonic cleaning and drying. Then 30 mM zinc acetate was dissolved in ethanol to prepare a seed solution. Place the quartz substrate on a spin coater, drop the prepared seed crystal solution on the surface, and spin coat after standing for 5 minutes. The time is 5 minutes. Then place the quartz substrate grown with the seed crystal on a heating platform, heat rapidly at 200° C. for 30 minutes, and then cool down to room temperature naturally. Then accurately weigh 0.4205g of zinc acetate and 0.6585g of hexamethylenetetramine with an electronic balance, dissolve them in 100ml of deionized water, and stir quickly to obtain a mixed solution. The heat-treated quartz substrate was immersed in the mixed solution, and reacted at 90° C. for 5 hours. After the reaction, the obtained quartz substrate was taken out, washed with water, and dried at 70-80°C. Subsequently, 0.014 g...

Embodiment 2

[0037] This embodiment is similar to Embodiment 1, except that the heat-treated quartz substrate is immersed in the mixed solution and reacted at 90° C. for 4 hours. At the same time, the growth time of the GaOOH precursor was changed. In this example, the reaction was carried out at 70° C. for 5 hours. After the reaction, the obtained sample was taken out, washed with water, and dried at 70-80° C. Subsequently, the growth array samples were heated to 800° C., incubated for 1 hour, and then naturally cooled to room temperature. Paste the ITO glass with 0.2cm channel on the surface of the obtained core-shell array structure and fix it.

Embodiment 3

[0039] This embodiment is similar to embodiment 1, except that the heat-treated quartz substrate in embodiment 1 is immersed in the mixed solution and reacted at 90° C. for 3 hours. At the same time, the growth time of the GaOOH precursor was changed. In this example, the reaction was carried out at 70°C for 12 hours. After the reaction, the obtained sample was taken out, washed with water, and dried at 70-80°C. Subsequently, the growth array samples were heated to 800° C., incubated for 1 hour, and then naturally cooled to room temperature. Paste the ITO glass with 0.2cm channel on the surface of the obtained core-shell array structure and fix it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com