A kind of negative ion environmental protection paint and preparation method thereof

An environmentally friendly coating and negative ion technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of weak adsorption, which is not conducive to improving the air purification effect of coatings, so as to reduce the mixing of crosslinking agents and improve air purification effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0045] A Bi 2 o 3 / activated carbon, prepared according to the following steps: 1.5kg of 2.5% nitric acid solution and 1.5kg of absolute ethanol were added in the stirrer, after stirring for 30min at 300r / min, 1.5kg of Bi(NO 3 )·5H 2 O is added to the stirrer, stirred at 400r / min for 50min to obtain a transparent sol, put the transparent sol into the polytetrafluoroethylene liner of the hydrothermal reaction kettle, and put the polytetrafluoroethylene liner into the hydrothermal reaction kettle , then move the hydrothermal reactor into the oven, react at 120°C for 24 hours, take out the reactor, centrifuge the liquid in the polytetrafluoroethylene liner to obtain a solid product, put the solid product into the oven, and heat it at 80 After drying at ℃ for 6h, and then grinding the solid product, Bi 2 o 3 / activated carbon.

preparation example 2

[0047] A Bi 2 o 3 -TiO 2 / activated carbon, prepared according to the following steps:

[0048] (1) Add 1.5kg of tetrabutyl titanate and 4kg of absolute ethanol into the stirrer, and stir for 15min at 200r / min to obtain a titanium-containing solution;

[0049] (2) At 300r / min, add 1.5kg of nano activated carbon into the titanium-containing solution and stir for 15min to obtain a mixed solution;

[0050] (3) the 2.5% nitric acid solution of 1.5kg and the dehydrated alcohol of 1.5kg are mixed uniformly, obtain nitric acid alcohol solution;

[0051] (4) Under the stirring condition of 400r / min, the nitric acid alcohol solution and 1.5kg of Bi(NO 3 )·5H 2 O was added in the mixed solution, and after stirring for 60min, the sol was obtained;

[0052] (5) Add the sol to the polytetrafluoroethylene liner of the hydrothermal reaction kettle, put the polytetrafluoroethylene liner into the hydrothermal reaction kettle, and then move the hydrothermal reaction kettle into the oven....

Embodiment 1-7

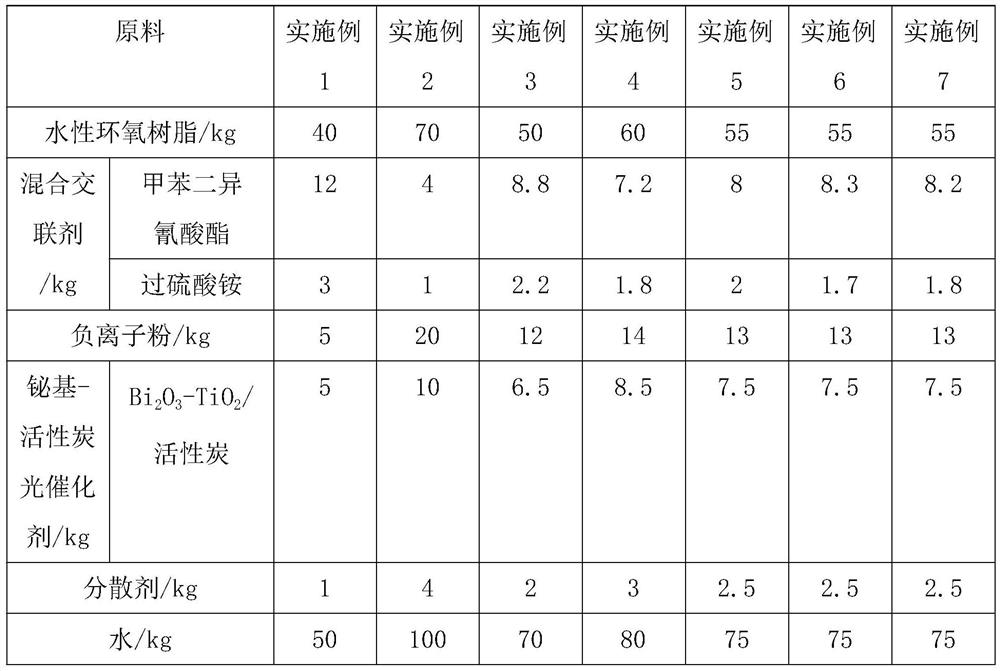

[0055] As shown in Table 1, the main difference of Examples 1-7 is that the proportioning of raw materials is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com