Flame-retardant ABS composite material and preparation method thereof

A composite material and ABS resin technology, applied in the field of flame retardant composite materials, can solve the problems of low flame retardant efficiency, large amount of flame retardants, poor mechanical properties of composite materials, etc., to improve the flame retardant effect and carbon content. High, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

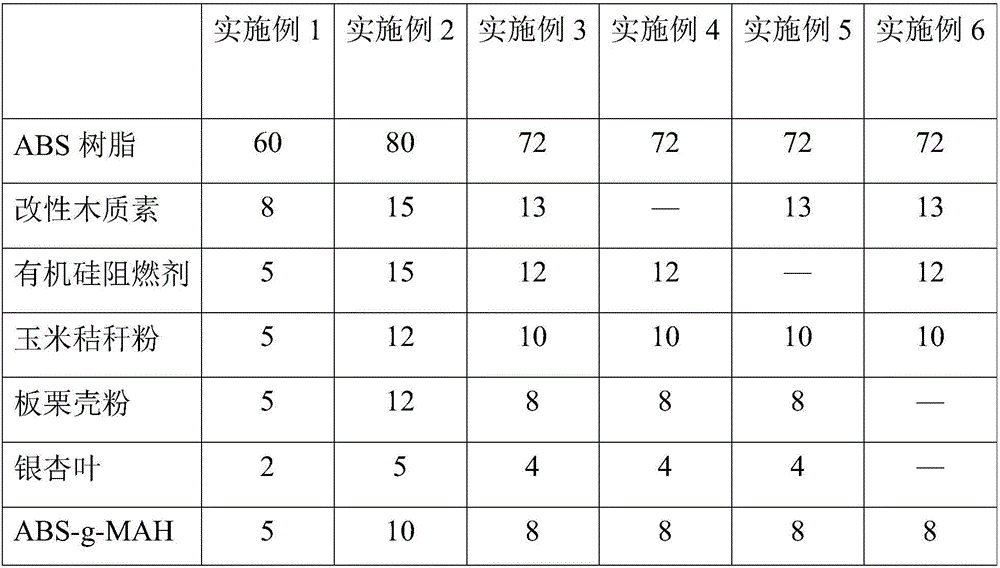

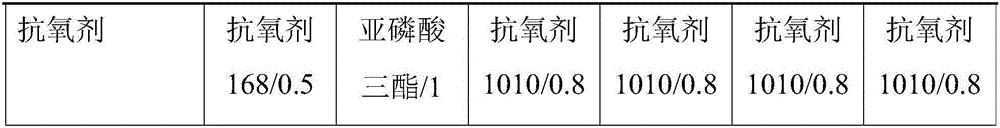

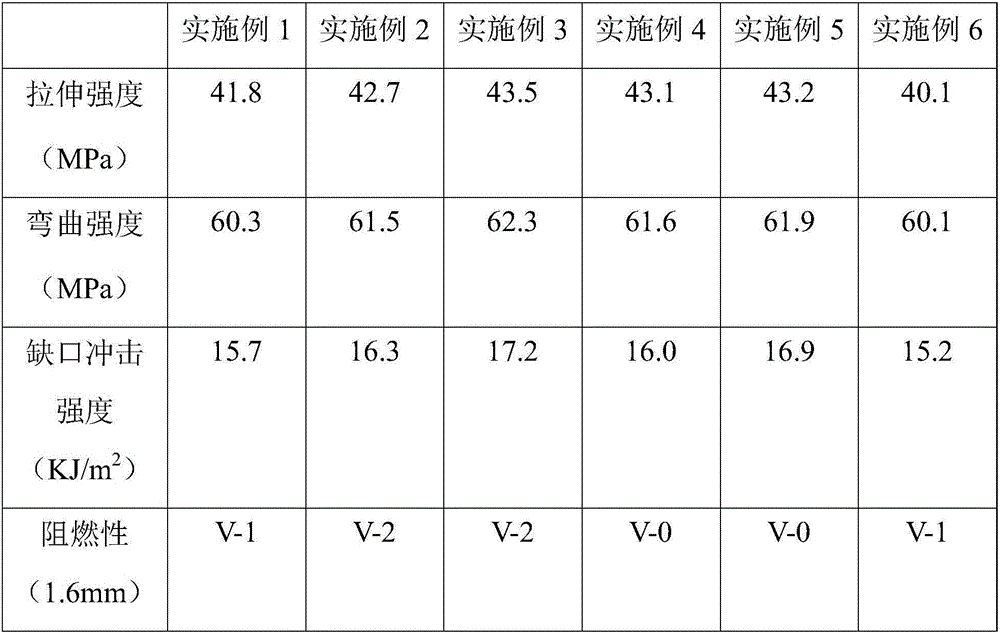

Embodiment 1

[0033] A flame-retardant ABS composite material, comprising the following components in parts by weight: 60 parts of ABS resin, 8 parts of modified lignin, 5 parts of organic silicon flame retardant, 5 parts of corn straw powder, 5 parts of chestnut shell powder, ginkgo biloba 2 parts, 5 parts of ABS-g-MAH and 0.5 parts of antioxidant; among them, corn straw powder, chestnut shell powder and ginkgo leaf are all dry matter; the particle size of corn straw powder and chestnut shell powder is 3-5mm; antioxidant The agent is antioxidant 168.

[0034] Modified lignin is prepared by the following method:

[0035] (1) Dissolving lignin in dimethyl sulfoxide to obtain a lignin solution; wherein, the volume ratio of the quality of lignin to dimethyl sulfoxide is 1:6g / mL;

[0036] (2) adding phosphorus pentoxide to the lignin solution obtained in step (1), and reacting at 100° C. for 4 hours; wherein, the mass ratio of phosphorus pentoxide to lignin is 1.5:1;

[0037] (3) dissolving m...

Embodiment 2

[0048] A flame-retardant ABS composite material, comprising the following components in parts by weight: 80 parts of ABS resin, 15 parts of modified lignin, 15 parts of organic silicon flame retardant, 12 parts of corn straw powder, 12 parts of chestnut shell powder, ginkgo biloba 5 parts, 10 parts of ABS-g-MAH and 1 part of antioxidant; among them, corn straw powder, chestnut shell powder and ginkgo leaf are all dry matter; the particle size of corn straw powder and chestnut shell powder is 3-5mm; antioxidant The agent is phosphite triester.

[0049] Modified lignin is prepared by the following method:

[0050] (1) Dissolving lignin in dimethyl sulfoxide to obtain a lignin solution; wherein, the volume ratio of the quality of lignin to dimethyl sulfoxide is 1:8g / mL;

[0051] (2) adding phosphorus pentoxide to the lignin solution obtained in step (1), and reacting at 120° C. for 2 hours; wherein, the mass ratio of phosphorus pentoxide to lignin is 2.5:1;

[0052](3) dissolvi...

Embodiment 3

[0063] A flame-retardant ABS composite material, comprising the following components in parts by weight: 72 parts of ABS resin, 13 parts of modified lignin, 12 parts of organic silicon flame retardant, 10 parts of corn straw powder, 8 parts of chestnut shell powder, ginkgo biloba 4 parts, 8 parts of ABS-g-MAH and 0.8 parts of antioxidant; among them, corn straw powder, chestnut shell powder and ginkgo leaf are all dry matter; the particle size of corn straw powder and chestnut shell powder is 3-5mm; antioxidant The agent is antioxidant 1010.

[0064] Modified lignin is prepared by the following method:

[0065] (1) dissolving lignin in dimethyl sulfoxide to obtain a lignin solution; wherein, the volume ratio of the quality of lignin to dimethyl sulfoxide is 1:7g / mL;

[0066] (2) adding phosphorus pentoxide to the lignin solution obtained in step (1), and reacting at 110° C. for 2 hours; wherein, the mass ratio of phosphorus pentoxide to lignin is 1.8:1;

[0067] (3) dissolvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com