High-efficient conny pressure gasification high-concentration sewage disposal method

A technology for pressurized gasification of crushed coal and sewage treatment method, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. The requirements of gasification and high-concentration sewage treatment and reuse, and the inability to meet environmental protection requirements, to achieve the effect of improving COD removal rate, improving biodegradability, avoiding blockage and wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

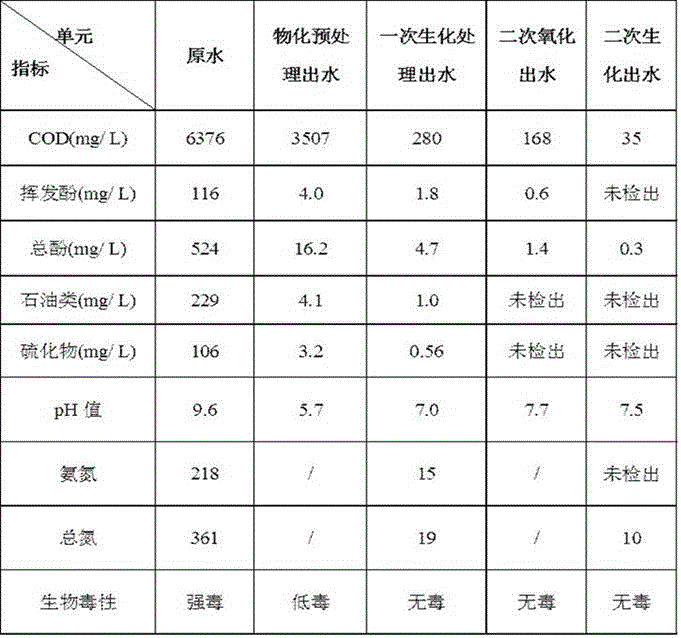

[0036] The method of the present invention is applied to high-concentration sewage from coal gasification of a crushed coal pressurized gasifier in Inner Mongolia. The specific influent water quality is shown in Table 1. The implementation process of sewage treatment is carried out according to the following steps.

[0037] Step 1. After homogeneous adjustment, the high-concentration sewage enters the pretreatment unit for oil removal and turbidity removal, and a polymerization-promoting initiator is added to precipitate and remove slick oil, emulsified oil and heavy oil.

[0038] Step 2. Pretreat the effluent for oil and turbidity removal for enhanced oxidation, and selectively oxidize and remove toxic and refractory organic substances such as phenols, petroleum, and aromatic hydrocarbons in the sewage, reduce toxicity and improve biodegradability; specific methods can use existing technologies, For example, in ZL 200710131116.9, an enhanced oxidation process for organic toxi...

Embodiment 2

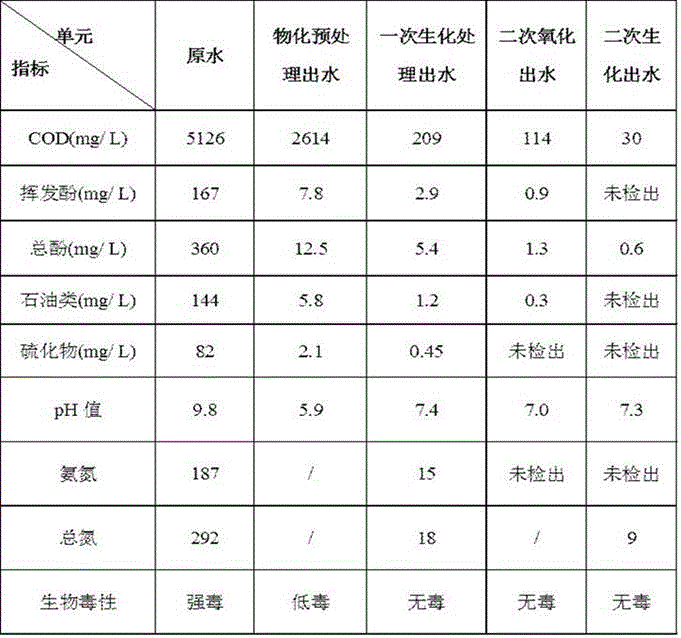

[0046] The high-concentration sewage of Henan crushed coal pressurized gasifier coal gasification, the specific influent water quality is shown in Table 2. The reaction steps are the same as in Example 1, and the specific reaction parameters are as follows.

[0047] In step 1, a polymerization-promoting initiator is added to realize the polymerization and sedimentation of the oily substance containing unsaturated bonds and the suspended matter in the wastewater. The concentration of the initiator is 0.2g / ton of wastewater, and the reaction time is 0.6h. The pretreated effluent flows into the split-flow two-stage anoxic / aerobic system, and the oxidized effluent flows into the two-stage A pools in different proportions. In step A, the operating pressure in the catalytic draft tube is 0.22Mpa, and the hydraulic retention time is 0.4h. In step B, the waste water flowing to the bottom of the catalytic oxidation tower is drawn out, and the reflux ratio is controlled to 300%. The s...

Embodiment 3

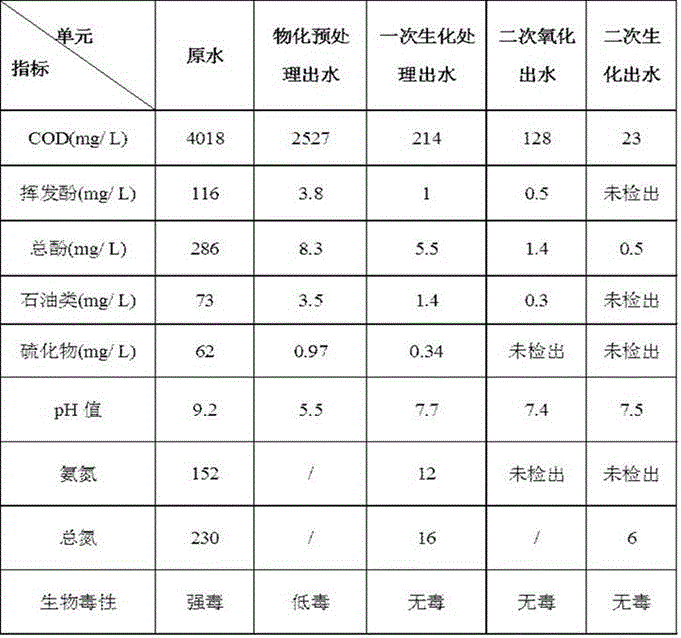

[0051] Xinjiang crushed coal pressurized gasifier coal gasification high-concentration sewage, see Table 3 for specific influent water quality. The reaction steps are the same as in Example 1, and the specific reaction parameters are as follows.

[0052] In step 1, a polymerization-promoting initiator is added to realize the polymerization and sedimentation of the oily substance containing unsaturated bonds and the suspended matter in the wastewater. The concentration of the initiator is 0.4g / ton of wastewater, and the reaction time is 1h. The pretreated effluent flows into the split-flow two-stage anoxic / aerobic system, and the oxidized effluent flows continuously into the two-stage A pools in different proportions. The ratio of the first-stage A pool to the second-stage A pool is 20:1. In step A, the operating pressure in the catalytic draft tube is 0.35Mpa, and the hydraulic retention time is 0.5h. In step B, the waste water flowing to the bottom of the catalytic oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com