Intelligent high-safety lithium-on battery with polymer skeleton

A technology of lithium-ion batteries and smart polymers, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of avoiding thermal volatilization and decomposition, small internal resistance, and superior electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

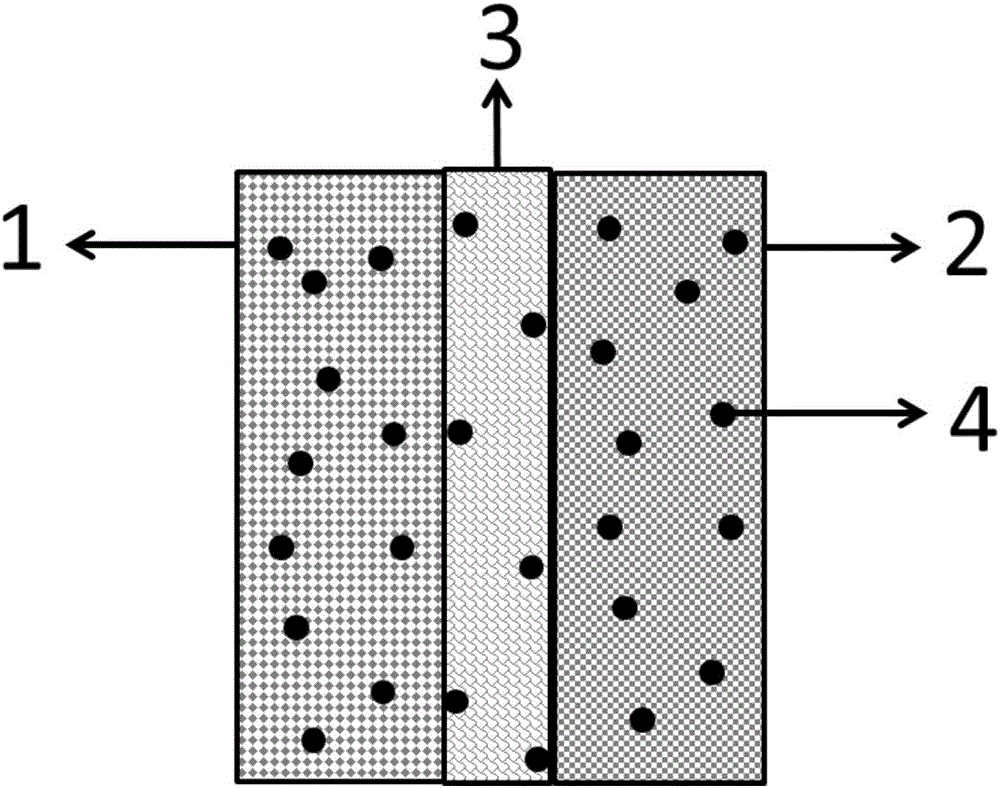

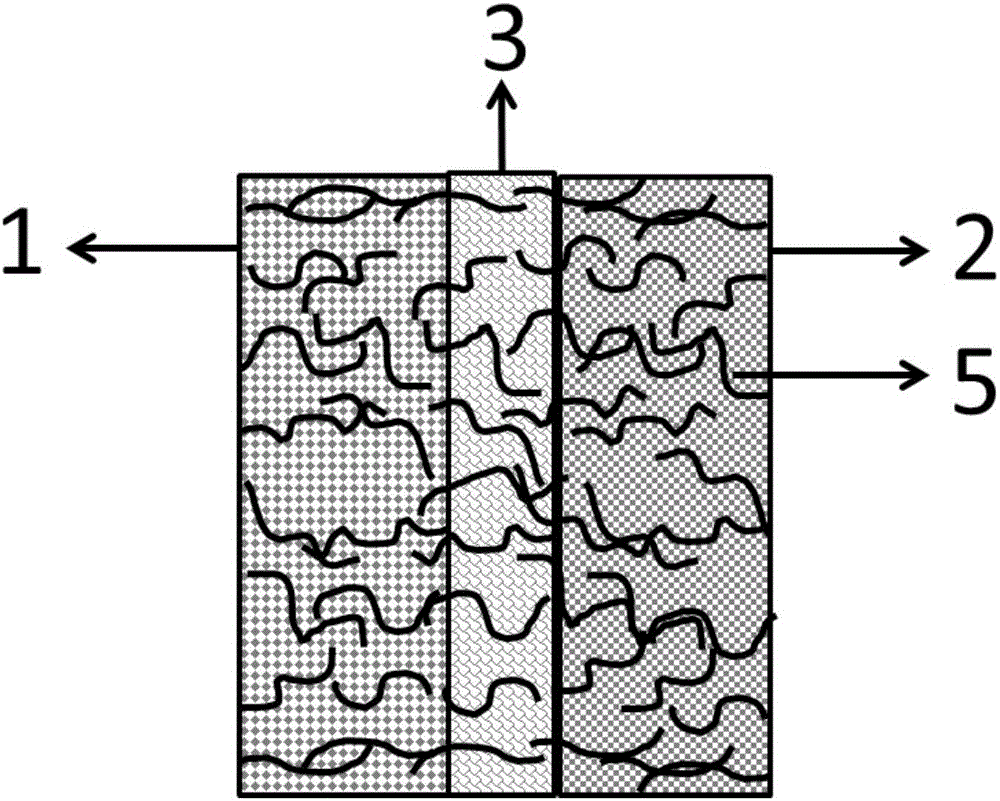

Image

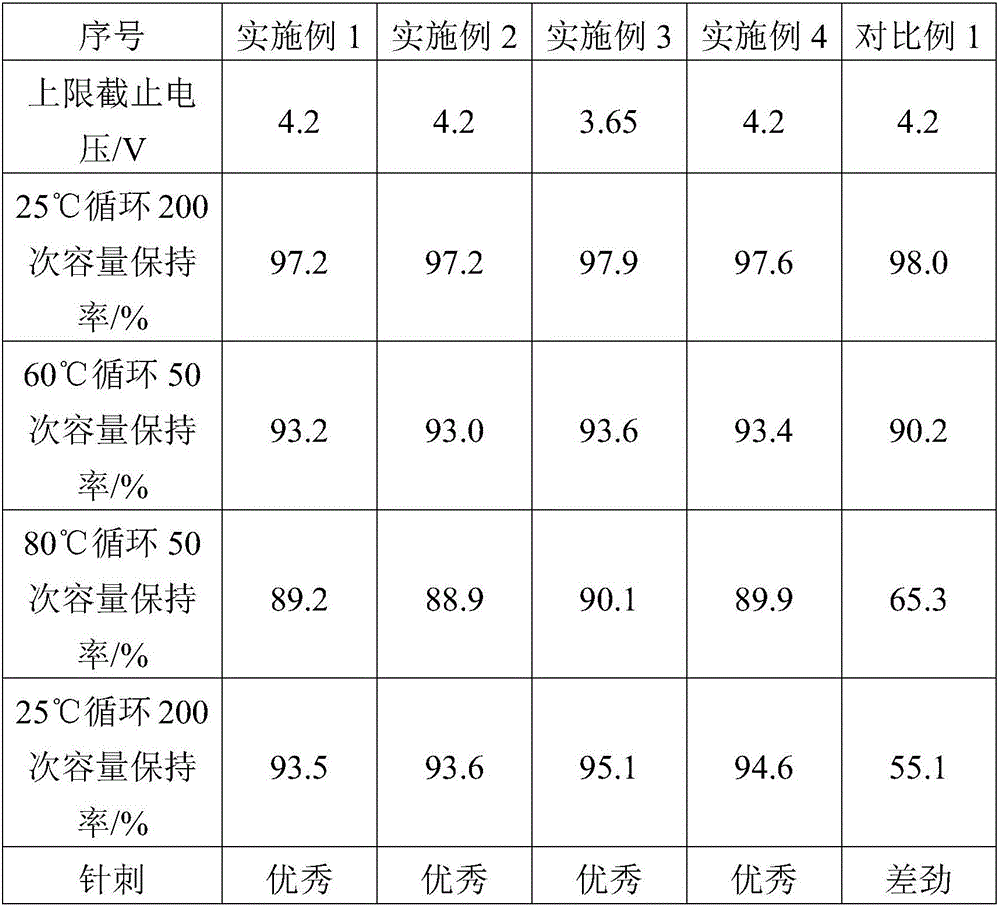

Examples

Embodiment 1

[0022] The positive temperature temperature-sensitive polymer particles in this example are polysulfodimethylammonium isobutylene ester particles with a weight-average molecular weight of 100,000 and a particle size of 0.5 μm. The positive electrode is composed of nickel-cobalt-manganese ternary, polysulfodimethylammonium isobutylene ester particles, polyvinylidene fluoride, and super P in a weight percentage of 92:1:3.5:3.5. The negative electrode is composed of artificial graphite, polysulfodimethylammonium isobutylene ester particles, hydroxymethyl cellulose, styrene-butadiene rubber, and super P according to the weight percentage of 92.5:1:2:3:1.5. The diaphragm is composed of porous polypropylene membrane surface coated with 2um thick polysulfodimethylammonium isobutylene ester particles. The electrolyte is composed of EC (ethylene carbonate): EMC (ethyl methyl carbonate): DEM (diethyl carbonate) according to the ratio of 1:1:1.2, and dissolves 1mol / L lithium hexafluoroph...

Embodiment 2

[0024] The positive temperature-type temperature-sensitive polymer particles in this example are polysulfobetaine particles with a weight-average molecular weight of 100,000 and a particle size of 0.4 μm. The positive electrode is composed of nickel-cobalt-manganese ternary, polysulfobetaine particles, polyvinylidene fluoride, and super P according to the weight percentage of 93:1.5:3:2.5. The negative electrode is composed of graphene, silicon monoxide, polysulfobetaine particles, hydroxymethylcellulose, styrene-butadiene rubber, and super P in a weight percentage of 80:10:2:2:3:3. The separator consists of a porous polyethylene membrane coated with 1.5um thick polysulfobetaine particles. The electrolyte is composed of EC (ethylene carbonate): EMC (ethyl methyl carbonate): DEM (diethyl carbonate) according to the ratio of 1:1.5:1, and dissolves 1.2mol / L lithium hexafluorophosphate. The positive electrode sheet, diaphragm, and negative electrode sheet are stacked in sequence ...

Embodiment 3

[0026] The positive temperature temperature-sensitive polymer particles in this example are poly(N-isopropylacrylamide) particles with a weight average molecular weight of 50,000 and a particle size of 10 μm. The positive electrode is composed of lithium iron phosphate, poly(N-isopropylacrylamide) particles, polyvinylidene fluoride, and superP according to the weight percentage of 93:1.5:3:2.5. The negative electrode is composed of graphene, silicon monoxide, poly(N-isopropylacrylamide) particles, hydroxymethyl cellulose, styrene-butadiene rubber, and super P in a weight percentage of 85:5:2:2:3:3. The diaphragm consists of a porous polyvinylidene fluoride membrane coated with 1 μm thick poly(N-isopropylacrylamide) particles. The electrolyte is composed of EC (ethylene carbonate): EMC (ethyl methyl carbonate): DEM (diethyl carbonate) according to the ratio of 1:1:1, and dissolves 1mol / L lithium hexafluorophosphate. The positive electrode sheet, diaphragm, and negative electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com