Equipment and process using methanol splitting decomposition to produce direct reduced iron

A technology for methanol cracking and iron reduction, applied in furnace types, furnaces, shaft furnaces, etc., can solve problems such as failure to take environmental protection measures, and achieve significant economic and social benefits, high production efficiency, and high gas utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

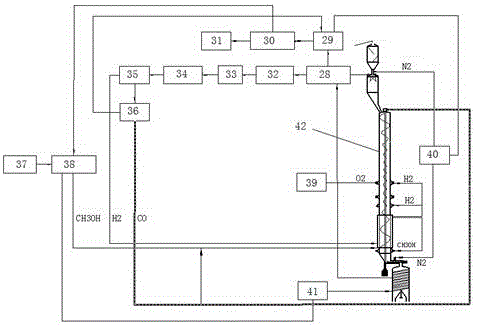

[0042] figure 1 It shows that the main body of the present invention is a gas-based reduction shaft furnace 42, and the supporting equipment includes a waste heat recovery device 28, a superheater 29, a back pressure steam turbine 30, a generator 31, a cyclone dust collector 32, a condenser 33, and a bag filter 34 , the first pressure swing adsorption tower 35, the second pressure swing adsorption tower 36, methanol storage tank 37, methanol vaporizer 38, oxygen generator 39, nitrogen generator 40, water tank 41.

[0043] The process flow of the present invention will be specifically described below in conjunction with the equipment of the present invention.

[0044] figure 1 It is shown that the waste heat recovery device 28 is connected to the tail gas exhaust port 9 of the tail gas separation chamber 6, and the tail gas separated from the tail gas separation chamber 6 is discharged into the waste heat recovery device 28 through the exhaust port 9, where the tail gas at 350...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com