Double-network hydrogel based on PEG (polyethylene glycol) and polysaccharides as well as preparation method and application of double-network hydrogel

A hydrogel and double-network technology, applied in the field of double-network hydrogel based on PEG and polysaccharides and its preparation, can solve problems such as inability to prepare shapes, achieve rapid recovery and reorganization, excellent biocompatibility, and The effect of reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

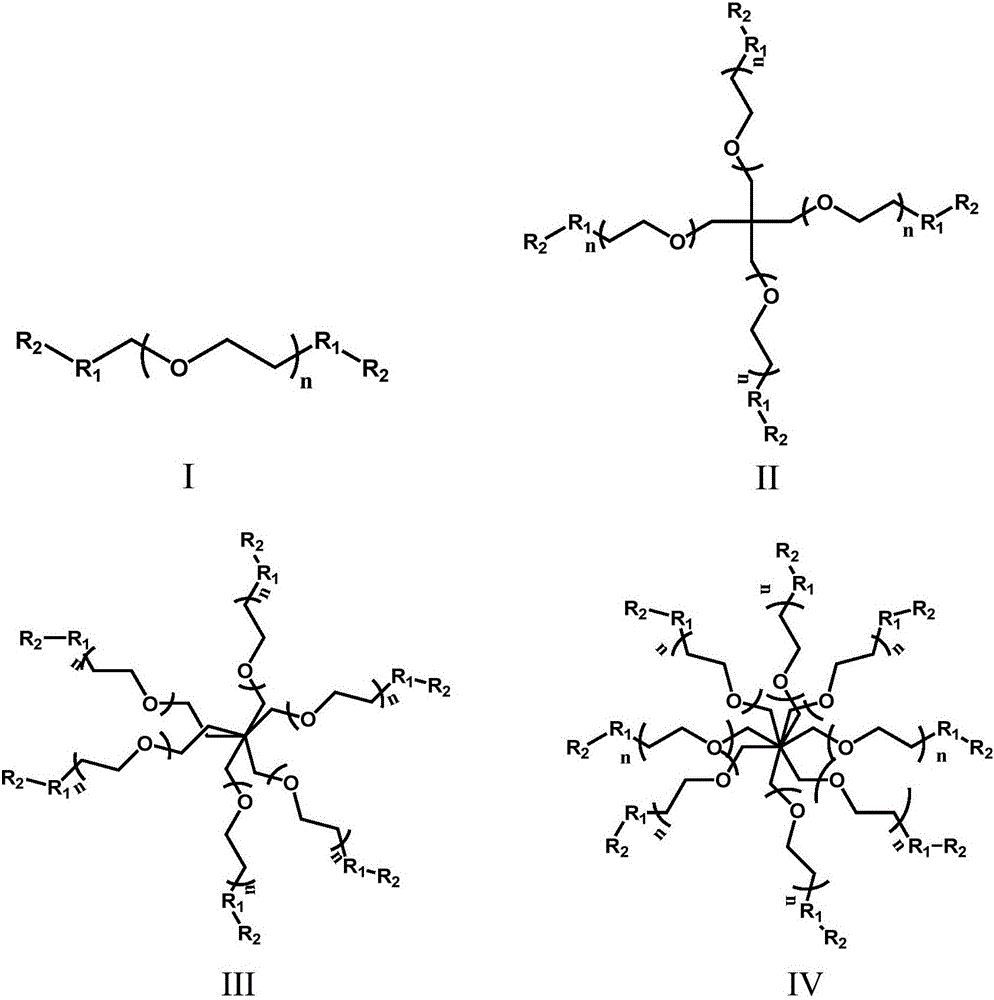

[0073] (1) Weigh 200 mg of high-strength agarose and dissolve it in 10 mL of PBS buffer solution, heat to 120 ° C and cool to 50 ° C, take 5 mL and add 400 mg of four-armed polyethylene glycol amino (as shown in formula II, wherein, n is 56, R 1 is an ether bond, R 2 is amino) and 400mg four-arm polyethylene glycol succinimide ester (as shown in formula II, wherein, n is 56, R 1 is an ester bond, R 2 succinimide ester) to obtain mixed solution 1 and mixed solution 2; draw a mixed solution with one of the double-barreled syringes respectively, then inject it into a glass mold, and wait for cooling to room temperature for 3 hours to obtain chemical-physical double network water gel.

[0074] The obtained chemical-physical double network hydrogel was tested, and the compressive strength was 28MPa, and the compressive deformation rate was over 97%.

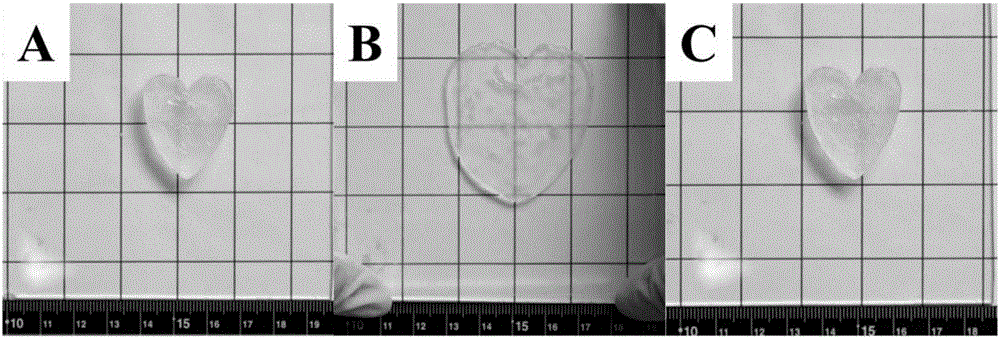

[0075] After the gel prepared in this example is compressed, it can recover to the original compressive strength after being hea...

Embodiment 2

[0077] Weigh 200 mg of conventional agarose and dissolve in 10 mL of PBS buffer solution, heat to 100 ° C and cool to 50 ° C, respectively take 5 mL and add 400 mg of four-arm polyethylene glycol alkynyl (as shown in formula II, wherein n is 56 , R 1 is an ether bond, R 2 is alkynyl) and 400mg four-arm carboxy azide (as shown in formula II, wherein, n is 56, R 1 is an ether bond, R 2 azide) to obtain mixed solution 1 and mixed solution 2; draw a mixed solution with one of the double-barreled syringes respectively, then inject it into a mold, and wait for cooling to room temperature for 2 hours to obtain a chemical-physical double network hydrogel.

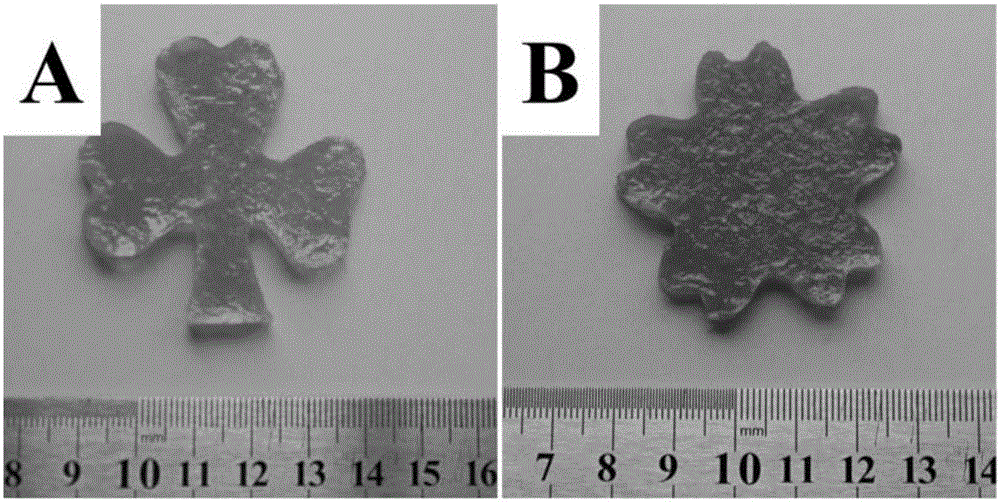

[0078] Different shapes of hydrogels can be obtained by using different molds, such as figure 2 As shown, clover-shaped and snowflake-shaped hydrogels can be prepared.

Embodiment 3

[0080] Weigh 200 mg of low-melting point agarose and dissolve in 10 mL of PBS buffer solution, heat to 80 ° C and cool to 50 ° C, respectively take 5 mL and add 400 mg of four-armed polyethylene glycol thiol (as shown in formula II, wherein n is 56 , R 1 is an ether bond, R 2 is mercapto) and 400mg four-arm polyethylene glycol succinimide ester (as shown in formula II, wherein, n is 56, R 1 is an ester bond, R 2 succinimide ester) to obtain mixed solution 1 and mixed solution 2; use one of the double-barreled syringes to draw a mixed solution, then inject it into the mold, and wait for cooling to room temperature for 4 hours to obtain the chemical-physical double network hydrogel glue.

[0081] The obtained chemical-physical double network hydrogel was tested, and the compressive strength was 38MPa, and the compressive deformation rate was over 98%. After the gel is compressed, it can recover to its original compressive strength by heating to 60°C for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com