A piezoelectric ceramic material with high Curie temperature and high temperature stability, its preparation method and application

A technology of piezoelectric ceramics and ceramic materials, applied in the field of materials science and engineering, can solve the problems of small resistivity, unfavorable device production, unfavorable device preparation and stable operation, and achieve the effect of improving piezoelectric performance and excellent temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of bismuth yttrium niobate calcium lithium cerium ceramic powder by solid phase method

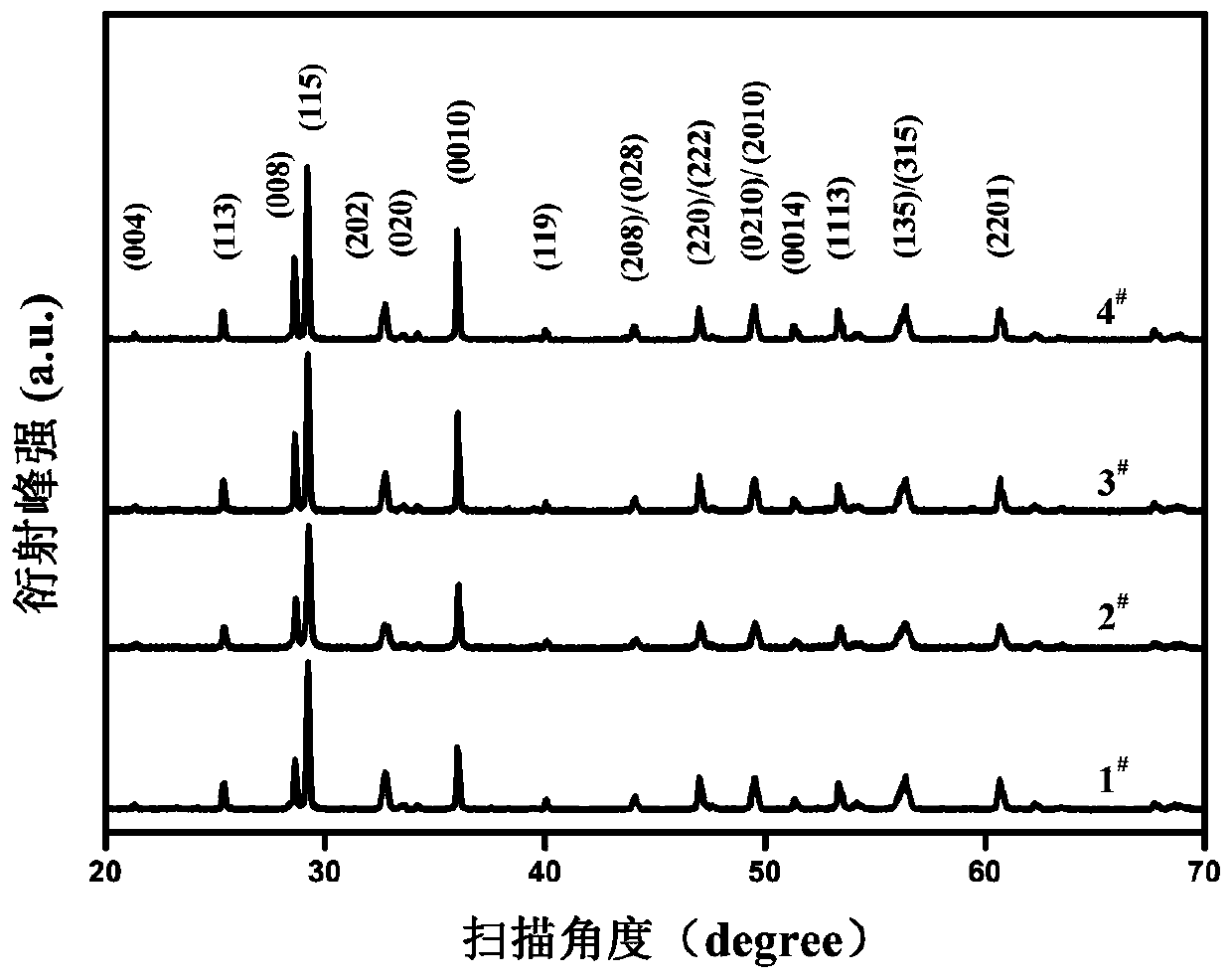

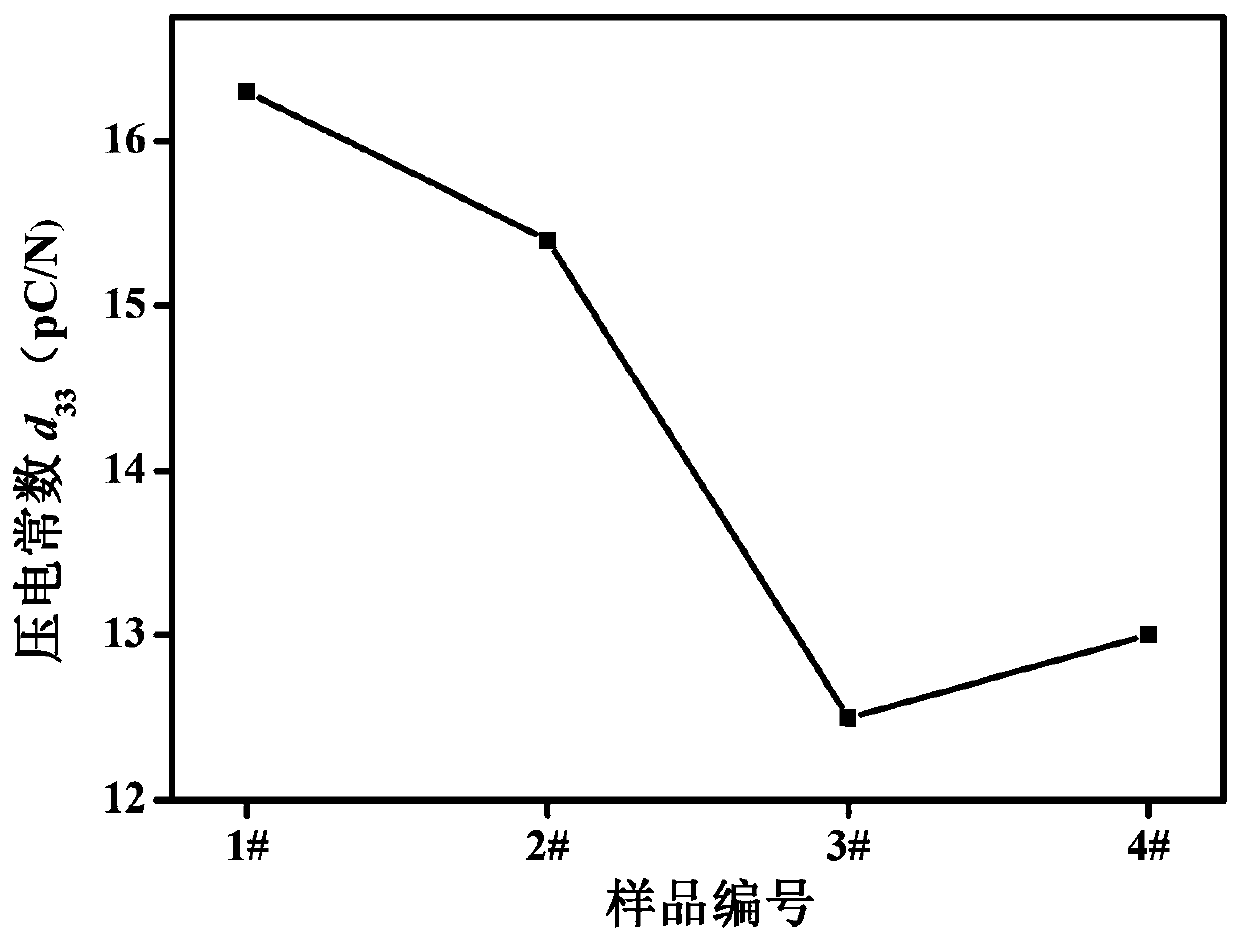

[0034] The raw materials were divided according to the general formula Ca 0.92 Li 0.04 Ce 0.03 Y 0.01 Bi 2 Nb 2 o 9 ( x =0.04, y =0.03, z =0.01, number 1 # ), Ca 0.92 Li 0.04 Ce 0.02 Y 0.02 Bi 2 Nb 2 o 9 ( x =0.04, y =0.02, z =0.02 number 2 # ) for weighing and batching, put it in a polyurethane ball mill tank, use absolute ethanol as the dispersion medium, and use a planetary ball mill for 24 hours after ball milling at a speed of 300rpm, bake it under a drying lamp for 2 hours to make it dry, and then control the temperature in the program The temperature was continuously raised to 850° C. in a box furnace, and kept for 3 hours to obtain bismuth yttrium niobate calcium lithium cerium ceramic powder.

[0035] (2) Secondary ball milling

[0036] The prepared bismuth yttrium niobate calcium lithium cerium ceramic powder was placed in a polyuretha...

Embodiment 2

[0044] (1) Preparation of bismuth yttrium niobate calcium lithium cerium ceramic powder by solid phase method

[0045] Raw material according to general formula Ca 0.92 Li 0.04 Y 0.04 Bi 2 Nb 2 o 9 ( x =0.04, y =0, z =0.04) for weighing and batching, put it in a polyurethane ball mill tank, use absolute ethanol as the dispersion medium, and use a planetary ball mill for 24 hours after ball milling at a speed of 300rpm, bake it under a drying lamp for 2 hours to make it dry, and then The temperature was continuously raised to 850° C. in a temperature-controlled box-type furnace and kept for 3 hours to obtain bismuth-yttrium-bismuth-calcium-lithium-cerium ceramic powder.

[0046] (2) Secondary ball milling

[0047] The prepared bismuth yttrium niobate calcium lithium cerium ceramic powder was placed in a polyurethane ball mill tank, with absolute ethanol as the dispersion medium, after ball milling with a planetary ball mill for 12 hours, the rotating speed was 300rpm, ...

Embodiment 3

[0055] (1) Preparation of bismuth yttrium niobate calcium lithium cerium ceramic powder by solid phase method

[0056] Raw material according to general formula Ca 0.92 Li 0.04 Ce 0.04 Bi 2 Nb 2 o 9 ( x =0.04, y =0.04, z =0) for weighing and batching, put it in a polyurethane ball mill tank, use absolute ethanol as the dispersion medium, and use a planetary ball mill for 24 hours after ball milling at a speed of 300rpm, bake it under a drying lamp for 2 hours to make it dry, and then The temperature was continuously raised to 850° C. in a temperature-controlled box-type furnace and kept for 3 hours to obtain bismuth-yttrium-bismuth-calcium-lithium-cerium ceramic powder.

[0057] (2) Secondary ball milling

[0058] The prepared bismuth yttrium niobate calcium lithium cerium ceramic powder was placed in a polyurethane ball mill tank, with absolute ethanol as the dispersion medium, after ball milling with a planetary ball mill for 12 hours, the rotating speed was 300rpm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com