Method for preparing sodium bismuth titanate piezoelectric ceramic from low-granularity powder

A technology of piezoelectric ceramics and sodium bismuth titanate, which is applied in the field of piezoelectric ceramics preparation, can solve the problems of piezoelectric performance and high-temperature resistivity. There are few studies on the influence of high-temperature resistivity, which cannot meet the actual use requirements and affect high-temperature resistivity. and other problems, to achieve the effect of increasing the remnant polarization strength, improving the polarization effect, and improving the high temperature resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1), ingredients

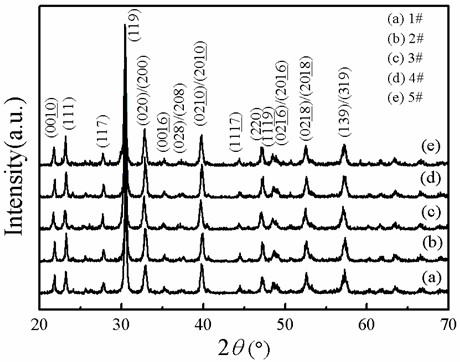

[0036] Chemically pure raw material Na with mass purity ≥ 99% 2 CO 3 、 Bi 2 o 3 、TiO 2 、 Ta 2 o 5 、WO 3 and Sm 2 o 3 According to the measurement formula: Na 0.5 Bi 4.5 Ti 3.95 Ta 0.025 W 0.025 o 15.0375 +0.1wt%Sm 2 o 3 The calculated dosage ratio is accurately weighed and mixed. Put the mixed raw materials into a ball mill tank and use a planetary ball mill for ball milling. The grinding balls use agate balls. The agate balls are composed of φ10mm agate balls, φ5mm agate balls and φ3mm agate balls. The weight ratio is 3:4:3. Ethanol is the dispersion medium, the weight ratio of agate balls, raw materials, and absolute ethanol is 5:2:3, the ball milling time is 8 hours, and the frequency of the ball mill is 33.5Hz. Grind in a mortar and pass through a 40-mesh sieve to form a mixed powder.

[0037] (2), synthesis

[0038] Put the mixed powder sieved in step (1) into a crucible, compact it, cover it, seal it, synthesize it in a synt...

Embodiment 2

[0050] (1), ingredients

[0051] Chemically pure raw material Na with mass purity ≥ 99% 2 CO 3 、 Bi 2 o 3 、TiO 2 、 Ta 2 o 5 、WO 3 and Sm 2 o 3 According to the measurement formula: Na 0.5 Bi 4.5 Ti 3.95 Ta 0.025 W 0.025 o 15.0375 +0.1wt%Sm 2 o 3 The calculated dosage ratio is accurately weighed and mixed. Put the mixed raw materials into a ball mill tank and use a planetary ball mill for ball milling. The grinding balls use agate balls. The agate balls are composed of φ10mm agate balls, φ5mm agate balls and φ3mm agate balls. The weight ratio is 3:4:3. Ethanol is the dispersion medium, the weight ratio of agate balls, raw materials, and absolute ethanol is 5:2:3, the ball milling time is 8 hours, and the frequency of the ball mill is 33.5Hz. Grind in a mortar and pass through a 40-mesh sieve to form a mixed powder.

[0052] (2), synthesis

[0053] Put the mixed powder sieved in step (1) into a crucible, compact it, cover it, seal it, synthesize it in a synth...

Embodiment 3

[0065] (1), ingredients

[0066] Chemically pure raw material Na with mass purity ≥ 99% 2 CO 3 、 Bi 2 o 3 、TiO 2 、 Ta 2 o 5 、WO 3 and Sm 2 o 3 According to the measurement formula: Na 0.5 Bi 4.5 Ti 3.95 Ta 0.025 W 0.025 o 15.0375 +0.1wt%Sm 2 o 3 The calculated dosage ratio is accurately weighed and mixed. Put the mixed raw materials into a ball mill tank and use a planetary ball mill for ball milling. The grinding balls use agate balls. The agate balls are composed of φ10mm agate balls, φ5mm agate balls and φ3mm agate balls. The weight ratio is 3:4:3. Ethanol is the dispersion medium, the weight ratio of agate balls, raw materials, and absolute ethanol is 5:2:3, the ball milling time is 8 hours, and the frequency of the ball mill is 33.5Hz. Grind in a mortar and pass through a 40-mesh sieve to form a mixed powder.

[0067] (2), synthesis

[0068] Put the mixed powder sieved in step (1) into a crucible, compact it, cover it, seal it, synthesize it in a synth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com