Method for synthesizing ordered mesopore nano-silica through pulverous coal

A nano-silica, fly ash technology, applied in the directions of silica, silica, chemical instruments and methods, etc., to achieve the effects of high mesoporous nanomaterial performance, shortening synthesis time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

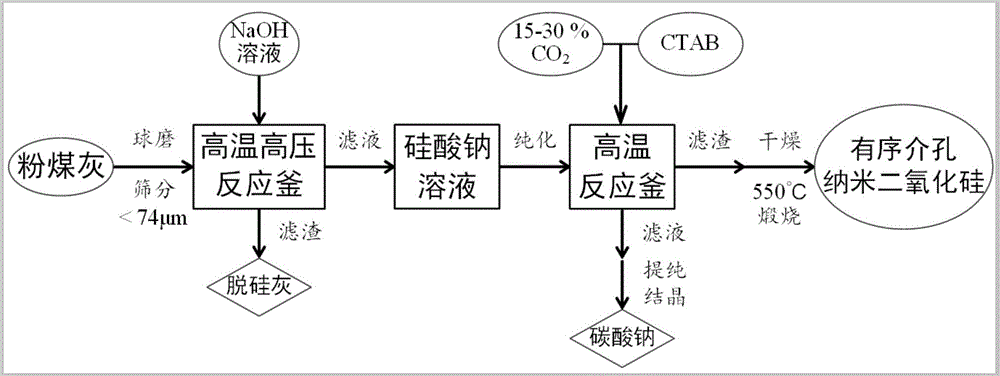

Method used

Image

Examples

Embodiment 1

[0040] (A) Take by weighing 168g, 84g, 14g and 14g of grinding balls of 3mm, 5mm, 8mm and 10mm respectively, take by weighing 140g of fly ash, place the ball and fly ash in a 250mL corundum ball mill jar, adjust the speed of the ball mill to 200rpm, ball milling time is 30min; use a 200-mesh sieve to sieve the fly ash after ball milling to obtain fly ash with a particle size of less than 74 μm for use.

[0041] (B) Accurately weigh 2.5g of NaOH solid, 5g of sieved fly ash and 7.5mL of pure water, add them to the lining of a 100mL high-temperature and high-pressure reactor, and react at 100°C for 60min.

[0042] (C) The mixed product in the step (B) is separated with a suction filtration device, and an appropriate amount of CO is passed into the filtrate 2 Gas, adjust the pH value to 10.8-11.3, remove impurities such as iron and aluminum, and then separate with a suction filtration device to obtain a secondary filtrate that is purified sodium silicate solution.

[0043] (D) Ad...

Embodiment 2

[0047] (A) Take by weighing 168g, 84g, 14g and 14g of grinding balls of 3mm, 5mm, 8mm and 10mm respectively, take by weighing 140g of fly ash, place the ball and fly ash in a 250mL corundum ball mill jar, adjust the speed of the ball mill to 250rpm, ball milling time 20min; use a 200-mesh sieve to sieve the fly ash after ball milling to obtain fly ash with a particle size of less than 74 μm for use.

[0048] (B) Accurately weigh 2.5g of NaOH solids, 5g of sieved fly ash and 7.5mL of pure water, add them to the lining of a 100mL high-temperature and high-pressure reactor, and react at 110°C for 30min.

[0049] (C) The mixed product in the step (B) is separated with a suction filtration device, and an appropriate amount of CO is passed into the filtrate 2 Gas, adjust the pH value to 10.8-11.3, remove impurities such as iron and aluminum, and then separate with a suction filtration device to obtain a secondary filtrate that is purified sodium silicate solution.

[0050] (D) Adju...

Embodiment 3

[0054] (A) Take by weighing 168g, 84g, 14g and 14g of grinding balls of 3mm, 5mm, 8mm and 10mm respectively, take by weighing 140g of fly ash, place the ball and fly ash in a 250mL corundum ball mill jar, adjust the speed of the ball mill to 300rpm, ball milling time is 10min; use a 200-mesh sieve to sieve the fly ash after ball milling to obtain fly ash with a particle size of less than 74 μm for use.

[0055] (B) Accurately weigh 2.5g of NaOH solid, 5g of sieved fly ash and 7.5mL of pure water, add them to the lining of a 100mL high-temperature and high-pressure reactor, and react at 120°C for 15min.

[0056] (C) The mixed product in the step (B) is separated with a suction filtration device, and an appropriate amount of CO is passed into the filtrate 2 Gas, adjust the pH value to 10.8-11.3, remove impurities such as iron and aluminum, and then separate with a suction filtration device to obtain a secondary filtrate that is purified sodium silicate solution.

[0057] (D) Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com