Composite heat-preservation, fireproof and energy-conservation decorating plate and preparing method thereof

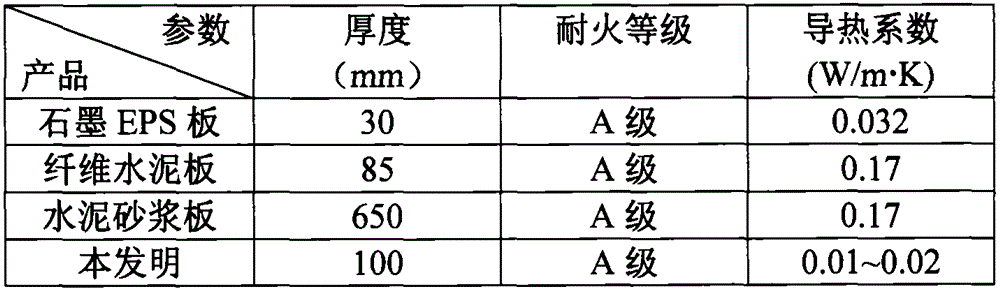

A technology of composite thermal insulation and decorative panels, which is applied in the direction of construction, building structure, floor, etc., can solve the problems of large difference in thermal expansion coefficient between the thermal insulation layer material and the decorative layer material, the product is prone to cracking, and there are potential safety hazards, etc., to achieve The effect of overcoming cracking, small difference in thermal expansion coefficient, and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] 1. 350 parts of fly ash (≤180 mesh), 100 parts of lime powder, calcium silicate (CaSiO 3 ) 20 parts, 20 parts of silicone amide foam stabilizer, 8 parts of aluminum powder suspension as raw materials, weighed by weight, stirred for 50 min (rotating speed: 450r / min), heated to 80, kept for 2 h, and left for 1 h After cutting, the cut material is placed in a steam-curing kettle at 200°C, the pressure is adjusted to 12Mpa, steam-cured for 1 hour, and cooled to room temperature to obtain an autoclaved aerated concrete block insulation layer; the self-developed nano-composite silicon material 120 Parts, lime powder (main ingredient: CaO) 200 parts, cement 30 parts, softwood pulp 30 parts, admixture 5 parts as raw materials, add water and stir for 30min (rotating speed: 300r / min) to obtain a slurry, then add the slurry The flow plate making machine is operated to obtain the embryonic plate, which is extruded for 40min (pressure: 40Mpa), pre-cultured at 60℃ for 6h, at 180℃ in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com