Boron-containing chitosan/polyvinyl alcohol composite fiber, preparation method thereof and non-woven fabric

A polyvinyl alcohol and composite fiber technology, applied in non-woven fabrics, conjugated synthetic polymer rayon, fiber chemical characteristics, etc., can solve problems such as poor mechanical properties of composite fibers, achieve good biocompatibility, eliminate The effect of peculiar smell and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

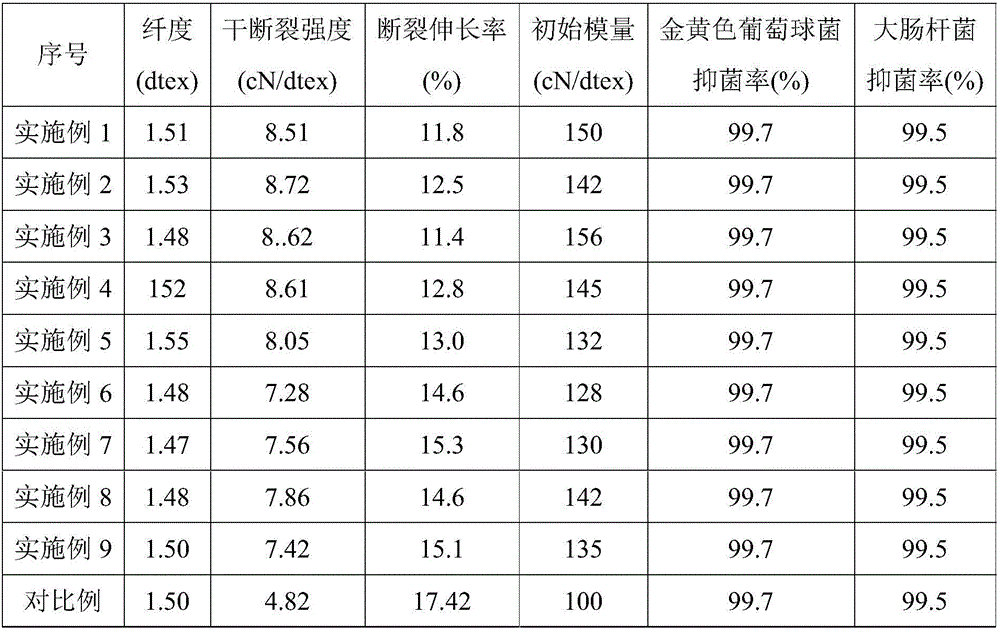

Examples

Embodiment 1

[0038]The boron-containing chitosan / polyvinyl alcohol composite fiber of this embodiment is mainly composed of the following components in mass percentage: 3% chitosan, 96.7% polyvinyl alcohol, and 0.3% boron. Among them, the degree of polymerization of polyvinyl alcohol is 1700-1800, the degree of alcoholysis ≥ 99%; the degree of deacetylation of chitosan > 93%.

[0039] The preparation method of the boron-containing chitosan / polyvinyl alcohol composite fiber of the present embodiment may further comprise the steps:

[0040] 1) Add polyvinyl alcohol to 50°C water and raise the temperature to 95°C, while stirring, add boric acid corresponding to the formula amount of boron, and stir until completely dissolved to obtain a polyvinyl alcohol solution; add the formula amount to the obtained polyvinyl alcohol solution Chitosan powder, fully stirred for 2 hours to mix, adjust the pH value of the system to 4.0, the temperature is 95 ° C, after filtration, stand for degassing for 6 ho...

Embodiment 2

[0044] The boron-containing chitosan / polyvinyl alcohol composite fiber of this embodiment is mainly composed of the following components in mass percentage: 4% chitosan, 95.7% polyvinyl alcohol, and 0.3% boron. Among them, the degree of polymerization of polyvinyl alcohol is 1700-1800, the degree of alcoholysis ≥ 99%; the degree of deacetylation of chitosan > 93%.

[0045] The preparation method of the boron-containing chitosan / polyvinyl alcohol composite fiber of the present embodiment may further comprise the steps:

[0046] 1) Add polyvinyl alcohol to 50°C water and raise the temperature to 95°C, while stirring, add boric acid corresponding to the formula amount of boron, and stir until completely dissolved to obtain a polyvinyl alcohol solution; add the formula amount to the obtained polyvinyl alcohol solution Chitosan powder, fully stirred for 2 hours to mix, adjust the pH value of the system to 6.0, and the temperature to 100 ° C, after filtration, stand for degassing fo...

Embodiment 3

[0050] The boron-containing chitosan / polyvinyl alcohol composite fiber of this embodiment is mainly composed of the following components in mass percentage: 5% chitosan, 94.6% polyvinyl alcohol, and 0.4% boron. Among them, the degree of polymerization of polyvinyl alcohol is 1700-1800, the degree of alcoholysis ≥ 99%; the degree of deacetylation of chitosan > 93%.

[0051] The preparation method of the boron-containing chitosan / polyvinyl alcohol composite fiber of the present embodiment may further comprise the steps:

[0052] 1) Add polyvinyl alcohol to 50°C water and raise the temperature to 95°C, while stirring, add boric acid corresponding to the formula amount of boron, and stir until completely dissolved to obtain a polyvinyl alcohol solution; add the formula amount to the obtained polyvinyl alcohol solution chitosan powder, fully stirred for 2 hours to mix, adjust the pH value of the system to 5.0, and the temperature to 95 ° C, after filtration, stand for degassing for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com